Asian Network for Quality (ANQ) Congress 2019 was held

by Standard and Quality Association of Thailand (SQAT) in The Berkeley Hotel, Bangkok,

Thailand from 21-25 Oct 2019. The congress theme was “Quality Innovation for

Sustainability”. Day 2 of Congress was

held on 24th Oct 2019. In the beginning, Minda and I took a photo

with Dr. Pramual

Suteecharuwat (Assistant Professor, Department of Industrial Engineering,

Faculty of Engineering, Chulalongkorn University, Thailand) in front of the ANQ

flag which made by her.

We also took a photo

with Ms. Larisa Fedyk (Head of the Central Organ the System, Federal Agency on

Technical Regulating and Metrology System of Voluntary Certification) and Mr.

Igor Pundel (Chairman of the Board of Directors the Systems, Federal Agency on

Technical Regulating and Metrology System of Voluntary Certification).

The first session I

attended was “Quality Management” and the first speaker was Dr. Ngo Van Nhon

(VQAH; Institute for Quality Assessment Development (IQAD)) and his

presentation topic entitled “ISO 21001: A New Management System Standard for

Educational Organizations (EOMS) – Studying and Implementation”. The new standard was more socially

responsible for offering educational services.

The ISO 21001:2018 standard

provided a great basis for education providers to enhance the quality of their

products and services. Then Dr. Ngo introduced the framework of EOMS and he

believed that if the standard was implemented, and complemented with best

practices in the field of education, it would help organizations yield positive

results for its beneficiaries – be it students, parents, community and

interested parties.

The second speaker was Mr.

Johnson Tan Swan San (Honorary Treasurer & Exco member, SQI) and his topic

named “Enhancement of a Laboratory Management System via Application and

Integration of Risk Management into ISO/IEC 17025:2017”. Firstly,

he briefed the requirements of the new version of ISO/IEC 17025:2017.

After DMAIC six sigma

process, Mr. Too achieved the target that cost reduction upto 16%. During Q&A, someone asked why used three

factors but only two factors during analysis phase. Mr. Too said because of time limitation and

constraint in the business world.

The third speaker was

Dr. Catherine Y.P. Chan and her presentation named “Quality Function Deployment

(QFD) Fosters Innovation”. She said in

order to endure existence in the market, enterprises had tried every mean to

seek for new products and services. So

that Innovation was key for sustainability in the long run.

Then Dr. Catherine Chan

briefed discussing methods for collecting VOC such as video recording,

visiting, etc. Since advancement of

Technology & Information Technology, she asked us to consider new media,

channels, methods and tools which could assist and support us on interacting

customers and acquiring a thoroughly understanding with needs.

Finally, Dr. Chan

introduced how QFD fostered innovation and she believed positive power

generated from the QFD process which would develop innovation naturally and

continuously.

The last speaker in this

session was Mr. DurgalPrasad (DP) Muthukrishnan (Director Consulting,

Cognizant) and his topic was “Enhancing Customer Experience (CX) in Digital

World through Quality Architecture”. Firstly,

he introduced Congizant which established in 1994 and to be NASDAQ since

1998. Then he addressed change of

Quality role through world class Quality Architecture.

And then Mr. DP

explained world class Quality Architecture solution evolved to address:

-

Product

quality improvement in line with ISO standards

-

Influence

business growth/outcome

He also explained the Quality

Architecture that product quality characteristics profiled based on the

business context and the economic benefits.

Finally, he explained 5

steps approach to setting up Quality Architecture Framework below.

1.

Customer

Experience Scanning (CX Scanning)

2.

Diagnostic

Study

3.

Analyse

and Benchmark

4.

Define

and Measure

5.

Improve

I met Dr. Takeshi Kaneko

in the venue and took a photo for memory.

After end of this

session, I went to the other session “Quality of Life”. Ms. Larisa Fedyk (Head of the Central Organ

the System, Federal Agency on Technical Regulating and Metrology System of

Voluntary Certification) was the last speaker and her topic named “All-Russian

Register - Projection into the future quality of life”.

Firstly, Ms. Larisa Fedyk presented All-Russian Register contribution and her presentation of ANQ award such as medical organization in the Nizhnevartovsk city polyclinic Nizhnevartovsk and different paper presentation in the field of health care such as lean medical production, etc. She also briefed their project named “Zemsky Doctor” and “Good to the Village” implemented in the Khanty-Mansi Autonomous District of Yugrap and presented in ANQ Congress 2018. Then she introduced different implementation project implemented in Center for Diagnostics and Cardiovascular Surgery (Surgut), Soviet District Hospital, Surgut Clinical Perinatal Center, Surgut District Clinical Hospital, Center for Professional Pathology, etc.

All speakers took a

group photo.

Then I took a photo with

Russian team - Ms. Larisa Fedyk, Mr. Mr. Igor Pundel and their interpreter.

During the tea break, I

took a photo with Prof. Satoko Tsuru (Professor, Healthcare Social System

Engineering Laboratory, School of Engineering, The University of Tokyo).

I also meet Japanese

friends included Dr. Masaaki Kaneko (Associate Professor, Tokai University),

Mr. Janak Mehta, Prof.

Yoshimichi Watanabe (Professor, Division of Engineering, Graduate School

Department of Interdisciplinary Research, University of Yamanashi, Japan), and

Mrs.

I also took photo with

Mr. Janak Mehta in front of the ANQ flag.

After that I attended

the session “Quality Innovation” for HKSQ member presentation.

When I arrived, the

speaker was Dr. Lien Nguyen thi Hoang (VQAH) and her presentation topic named

“Choosing a Networking Model of Laboratory Collaboration for Analysis Services

in Vietnam”. Dr. Lien said “When the free trade agreements that Vietnam signed

are effective, the control of goods through technical barriers will be more

focused, because the demand for testing and verifying the quality of goods is

growing.” Therefore, she proposed a

model provided networking foundation to member-laboratories on the basis of

strengthening their weak capacity and failure in order to meet the demand of

market.

Then she introduced

their research methodology in three phases.

After that she

demonstrated the preliminary survey results of the entire laboratory in

Vietnam. There were more than 900

laboratories in which only 165 laboratories were accredited by the Office of

Accreditation.

There were

two findings and the first one was summary of problems of the laboratory system

below.

-

Equipment

is not synchronized, has not invested equally and characteristics

-

There

is no mechanism to transfer research results in the field of testing

-

Lack

of technical support services (repair, supply of standards, equipment

calibration ...)

-

Lack

of information on testing capacity and legality of test results;

-

Laboratory

management capacity is limited and lack of professionalism

-

Performance

of equipment is not high

-

Most

research activities focus on basic research, few application products and

connect with industries

The second finding was to propose models of cooperative connection

system models and connection criteria.

Dr. Ivan C. Ng (City

University of Hong Kong) was the fourth speaker in this session and his topic

named “The Role of Corporate Culture in China’s 21 Century Industrialization:

An Investigation in Eastern China”. Firstly,

Dr. Ng introduced significant economic development in China in the first 15

years of the 21 century and 10 cluster industries of China’s Industry 4.0.

Then Dr. Ivan Ng briefed

his research workshop for different types of Chinese cultures such as

Paternalistic Leadership Culture (TC1), Artisan Spirit (TC2), Chinese Traditional

Thinking Culture (TC3), Work Attitude of “Just About Right” (差不多) (TC4), etc.

And then he demonstrated

his research framework – Study Model to find the relationship among Traditional

Culture (TC), Chinese Contemporary Culture (CC) and Critical Success Factors

(CSF).

Dr. Ng’s initial results

were showed as follows:

-

Enterprises

is to promote paternalistic culture in advancing of industrialization

-

Focus

on manufacturing and technology-intensive industries for industrialization

-

Decision

for industrialization are to consider artisan spirit

-

Organization

culture dimensions facilitate implementation for industrialization.

After that I went to the

session “Quality Management” and found that Dr. Tuan-Ho Le (Department of

Industrial & Management System Engineering, Dong-A University) presented

his paper named “Parameter estimation and optimization methodologies:

Artificial Neural Network modelling perspectives”. During Q&A, Dr. Le said it could be used

in Drug development.

The next speaker was Mr.

Yebeom Kim (Department of Industrial and Management Engineering, Inje

University) and his topic was “Applying the SERVQUAL and Kano model for

evaluating Service Quality in Fitness Industry”. Firstly, Mr. Kim proposed using the Kano-SERVQUAL

integrated approach to more accurately assess the quality of service in the

fitness industry.

The overall framework

with four stages were demonstrated.

In the detailed

procedure, one question was filled out with 2 SERVQUAL + 2 Kano = 4

questions. It needed to separate into

two sessions for analysis that one is for KANQ analysis and the other was

SERVQUAL analysis. Finally, he had 130

respondents for 22 items of fitness facility.

The last session I joined

in the morning was “Quality Management”.

The last speaker was Mr. Takaya Yamauchi (Department of Industrial

Administration, Tokyo University of Science) and his presentation topic entitled

“Recruitment Assistant Method using Video Interview”. His

study was focused on quality of hiring which was often performed based on each

interviewer.

Then Mr. Yamauchi

explained the background of vicious circle.

Finally, he showed how

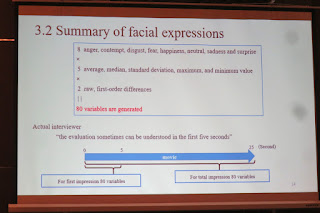

to measure facial expression using Microsoft Azure Face API that could

recognize eight expression included anger, contempt, disgust, fear, happiness, neutral,

sadness and surprise. Overall, it had generated

80 variables. Mr. Yamauchi introduced a

method of rating the interviewer's evaluation ability using the item response

theory (IRT) generalized partial scoring model used for estimating an

examination.

During lunch break, I

met Prof. Suzuki Tomomichi (Japan).

I also met Bangladesh

friends Mr. A.M.M. Khairul Bashar (President, Bangladesh Society for Total

Quality Management (BSTQM)) (middle) and Mr. Md. Nurul Haque (Principal

(Retired), Government Polytechnic Institute; BSTQM) (left).

In afternoon parallel

session “Quality Process”, the first speaker was Mr. Ranjay Kumar Singh (Head

Process Slab Casting, Tata Steel Ltd.) and his presentation named “Sticker

Pattern Recognition – The use of advanced analytics on engineered features to

detect sticker breakout in continuous casters”.

Firstly, he introduced the background and problem of Casting, Sticker

and Consequence of Sticker. The process included Blast Furnace, Steel Making,

Casting and Rolling.

Then he introduced the

sticker detection and recovery as well as its past algorithm. After that he introduced new approach such as

use of 3 year history of available patterns and merging data science and

physical reality of sticker, etc.

Finally, Mr. Singh

concluded his project timeline and scaling up plan after successfully achieved

75% reduction in false alarm and saving 1.2 million in reduction of quality downgrading

cost.

After Mr. Ranjay Kumar Singh

presentation, we took a photo with his friends for memory.

(Left: I, Mr. Ranjay Kumar Singh, Mr. Avinash

Kumar and Mr. Kartar Singh)

The last speaker in this

session was Dr. Mong Ka Fai, Alan (Deputy Project Manager, China Communications

Construction) and his presentation topic entitled “New Mechanically Automatic

Inclinometer System”. Dr. Mong

introduced Hong Kong reclamation and introduced inclinometer was one of major

equipment to measure the land deformation which was a common phenomenon in land

reclamation.

Then Dr. Mong compared

the conventional manual inclinometer and new mechanically automatic

inclinometer system. He identified

several advantages such as high efficiency, few human resource and higher level

of precision, etc.

The whole system and

data acquisition and transmission were explained in the following diagram. And then he briefed his research hypotheses

below.

RQ1. Is the mechanically

automatic system accurate than the manual system in measuring horizontal

displacement?

RQ2. Can the

mechanically automatic system be cheaper than the manual system in one-off

set-up and incurring cost?

RQ3. Can the

mechanically automatic system improve site safety by preventing injuries and

deaths than the manual system?

Lastly, Dr. Mong

concluded his results were positive that the mechanically automatic system

performed better than the traditional system in terms of measurement accuracy,

work efficiency, lower labour costs and lower risk of safety concerns.

Then Dr. Alan Mong

received certificate and took a photo with his wife for memory.

After that I took a

photo with all Postdoc participants from Hong Kong.

(Left: I, Dr. Keith Kwok-keung Wong (Deputy

Chair – The Chartered Institute of Plumbing and Heating Engineering), Dr. Alan

K.F. Mong (Deputy Project Manager, China Communications Construction) and Dr.

Lam Kong Ngan Kenny (Founding President, Shenzhen-Hong Kong Institute of

Professional Management Association))

In the Panel Session, we

were well prepared to learn from the coming keynote speakers.

Our Singapore friend Mr.

Kitson Leonard Lee chaired this session.

The first

keynote speaker was Prof. Ching-Chow Yang (President, CSQ) and his presentation

topic entitled “Quality 、Innovation

and Sustainability”. Firstly,

Prof. Yang briefed the changes from quality concept to sustainability from 1900

to 2000 in which had different stages from Product standard (1900) to Product

quality (1930), to Customer-focused (1970), to Innovative quality (1990) and

then to Sustainability (2000).

Then Prof. Yang introduced

the framework of innovation system of TSMC.

He said TSMC established in 1987 and headhquartered in Hsinchu Science

Park, Taiwan. TSMC pioneered the

innovative pure-play foundry business model by focusing solely on manufacturing

customers’ semiconductor product. TSMC focused on four perspectives and they

were Best Quality, Customer Service, Innovation-focused and Sustainable

Products.

After that Prof. Yang

mentioned the progress of green system in TSMC from code compliance to

voluntary carbon reduction.

Finally, Prof. Yang

briefed TSMC CSR award achievement and their sustainability implementation involved

Risk Management, Social Responsibility and Green that achieved different green

related management system standards.

The second keynote

speaker was Ms. Victoria Yakimova (Head of perspective development, Department

of Academy of Standardization, Metrology and Certification, ROQ, Russia,

Novosibirsk) and her topic named “Quality Innovation for Sustainability in

Russia”. Firstly, she introduced that

Russia had 1/8 of the land in the world with 11 time zones.

Then she mentioned their

President formed strategy of scientific and technical development of Russia

that “Sustainable, Dynamic and Balanced Development of Russia for the next 10

years.” They had 9 national goals for

priority national projects.

Finally, Ms. Victoria

Yakimova introduced the award of the Government of the Russian Federation that award model was harmonized with EFQM

award for excellence. The competition established

in 1998 and separated into four nominations including Quality Leader, The Pride

of the Fatherland, Innovation and Import Substitution.

The last keynote speaker

was Dr. Ladawan Krasachol (Executive Vice President, National Science and

Technology Development Agency) and her presentation title named “Quality

Innovation - National Science and Technology Development Agency”.

In the beginning, Dr. Krasachol briefed the Quality Roadmap in Thailand from 1969 to 2003. The Quality Control Association was established in 1977 and Thai Standards Association (TSA) was founded in 1981. They combined to be The Standards & Quality Association of Thailand (SQAT) in 2001 and SQAT is ANQ Board Member. In 2000, Thailand started their TQM journey.

Then she introduced

their role of Research Organization to create/discover new knowledge and

applying it to provide solutions. Such

knowledge would extend to create innovation.

And then she briefed their Total Quality Concept.

After that Dr. Krasachol

stated to apply Quality Excellence Criteria for excellence practices in NSTDA

from Research to Innovation, from ideas to utilization.

Lastly, she concluded

that they expected to connect R&D to Economic Impact for Thailand 4.0. “Quality is a momentum to Thailand

Sustainability” she said at the end.

I presented HKSQ 30th

anniversary book and highlight to Dr. Ladawan Krasachol and took a photo for

memory.

After the panel session,

Dr. Panisuan Jamnarnwej (Chairman, ANQ; President, SQAT) presented souvenirs to

all keynote speakers and session chair.

And then Dr. Pansiuan

presented the ANQ Recognition for Excellence in Quality Practice (ARE-QP)

awards and took a group photo of winners.

Prof. Thanakom

Soontarnchainacksaeng (SQAT) reported the ANQ 2019 information and announced

the Best Paper Award.

Totally, ANQ Congress 2019

had 245 participants with 138 papers.

20 papers selected as

the best papers.

Hong Kong had two

winners and they were Dr. Mong Ka Fai, Alan

and Dr. Raymond W.L. Chan. (Since

Dr. Raymond Chan had business meeting in this afternoon, Dr. Keith Kwok-keung

Wong represented him to get the award.)

Singapore had one winner

and our good friend Mr. Too Meng Ken achieved it.

The ANQ Congress 2020

would be held in Korea. Prof. Matthew

Minsuk Shin (Korea) introduced the venue of Congress which held in Korea

Chamber of Commerce and Industry (KCCI) Grand Hall (http://english.korcham.net)

Finally, Dr. Panisuan

Jamnarnwej transferred the ANQ flag to Prof. Wan Sean Shin (Former

President – Korean Society for Quality Management).

At the end, Prof. Phulporn

Saengbangpla (Honorary Advisor, SQAT) gave closing remarks and gave special appreciation

to the only staff in SQAT.

Reference:

Asian Network for

Quality (ANQ) - http://www.anforq.org/

ANQ 2019 - http://www.anq2019.org/

20191022: Pre-ANQ

Congress 2019 visit to University in Songkla, Thailand and Congress Registration

- https://qualityalchemist.blogspot.com/2019/10/pre-anq-congress-2019-visit-to.html

20191023: ANQ Congress

2019 in Bangkok, Thailand – Day 1 (Part A) - https://qualityalchemist.blogspot.com/2019/10/anq-congress-2019-in-bangkok-thailand.html

20191023: ANQ Congress

2019 in Bangkok, Thailand – Day 1 (Part B) - https://qualityalchemist.blogspot.com/2019/10/anq-congress-2019-in-bangkok-thailand_23.html

20191024: ANQ Congress

2019 in Bangkok, Thailand – Day 2 - https://qualityalchemist.blogspot.com/2019/10/anq-congress-2019-in-bangkok-thailand_24.html

20191024: ANQ Congress

2019 in Bangkok, Thailand – Gala Dinner - https://qualityalchemist.blogspot.com/2019/10/anq-congress-2019-in-bangkok-thailand_78.html

20191024: ANQ Congress

2019 in Bangkok, Thailand – Technical Visit - https://qualityalchemist.blogspot.com/2019/10/anq-congress-2019-in-bangkok-thailand_25.html

沒有留言:

發佈留言