The Technical Seminar on Product Testing and Certification was held on 27 April 2013. The seminar was annually event and jointly organized by Department of System Engineering and Engineering Management of City University of Hong Kong (SEEM, CityUHK), Manufacturing and Industrial Engineering Section (MIES), The IET Hong Kong, and MILES Alumni Association of The Hong Kong Polytechnic University. Hong Kong Society for Quality (HKSQ) and America Society for Quality (ASQ - HK) were supporting organizations. The seminar aims to discuss and share the latest trends and technologies in testing and certification industry in Hong Kong and invited several experts to share their experiences and knowledge in the foods/food containers/toxicological testing. Moreover, I was honour to be invited as one of speakers to share Quality Journey on Technology Support Centre in HKSTP. The summary was shown below.

In the beginning, Prof. Kwok TSUI (Head of Dept. & Chair Professor of SEEM, CityU) gave a welcoming speech. He expressed that Quality was important in the Testing and Certification Industry.

Then Ir. Ho Chi Sing (Deputy Chairman, Hong Kong Quality Assurance Agency (HKQAA)) presented an opening remark. Ir. Ho pointed that the most important in the industry was Integrity. The he introduced HKQAA objective in the macroscopic view in Hong Kong.

After that IET and MILESAA presented souvenir to guest speakers and supporting organizations. I received the souvenir.

Dr. Xueping CHEN (CTO, Vitargent (International) Biotechnology Ltd.) received the souvenir. (Her company is HKSTP incubatee.)

Group photo of all speakers and representatives of supporting organizations

I (Quality Manager, BDTS of Hong Kong Science and Technology Parks Corporation) was the first speaker and my topic entitled "HKSTP - Technology Support Centre's ISO journey". Firstly, I shared our vision, mission and values.

After Science Park introduction, I briefed our ISO journey of ISO 9001, ISO 17025 (HOKLAS), ISO 27001 and OHSAS 18001 since 2003.

Eight Quality Management Principles were employed in Technology Support Centre (TSC). Then the HOKLAS work flow was briefed. After that ISO 27001 Information Security Management System development story was stated. Finally, Laboratory Safety organization and achievement was shared. We had planned to achieve ISO 14001 Environmental Management System in Laboratories in next year.

During the seminar, my friend Dr. Luk Chi Fai had also attended.

The second speaker was Dr. Xueping CHEN (Co-Founder & CTO, Vitargent (International) Biotechnology Limited) and her presentation was "Development of Innovative Biotests for estrogens and dioxins".

Dr. Chen introduced her company which was established in April 2010 and located in Hong Kong Science and Technology Park (HKSTP). Then she introduced their unique testing method such as Estrogen Disruptors testing, Fish Embryo Toxicity Testing ISO 15088 (HOKLAS accredited), etc.

(This achievement had published in HKSTPConnect at http://mail02.edm.hkstp.org/intimate/templates/images/hkstp_connect/40/en-us/news2.html.)

Their core technology was transgenic medaka which had developed which Dr. Chen studied in CityU for her PhD.

Before break, Ir. Lam Man-Kwan brief the membership of MILESAA and IET.

The third speaker was Mr. Wallace Luk (Technical Manager - Chemical Department, UL VS Hong Kong Limited) and his topic named "Safety of Food-contact utensils". Food contact utensils used different materials such as plastic, ceramic, stainless steel, glass and paper.

Mr. Luk reviewed the safety requirement for food contact articles (EU & US) and listed some common food regulations as follows.

- EU (EC 1935/2004, EC 10/2011, 84/500/EC, etc)

- FDA (21 CFR 175)

- LFGB (Formerly called LMBG)

- Japan Food Sanitation Law, others (GB, Taiwan, France, etc.)

Mr. Luk briefed the different requirements of different country that Some specific migration elements for plastic container included heavy metals, primary aromatic amines (PAA), melamine, formaldehyde, phthalates and bis-phenol A (BPA); for ceramic included lead and cadmium. The he introduced different analysis method to detect such migration.

The last speaker was Mr. Kenneth C.K. To (Assistant Sales Manager, Business Development Division, CMA Testing and Certification Laboratories) and his presentation topic was "The Importance of Food Safety and Microbiological Test".

Mr. To mentioned the key problem of food safety non-conformity in 2012. Some important cases were identified such as DEHP in wine. Many toxic event related to Chemical material (~52%) and harmful bacteria/microbes (~31%). After that Mr. To introduced Food Laws in Hong Kong and their real-time PCR testing for different bacteria/microbes.

Q&A session.

IET (HK) executive committee members and guest took a group photo at the end.

Reference:

SEEM of CityUHK - http://www.cityu.edu.hk/seem/

IET (HK) - http://www.theiet.org.hk/

MILES Alumni Association - http://www2.ise.polyu.edu.hk/milesaa/mission1.asp

HKSQ - http://www.hksq.org/index.asp

2013年4月28日星期日

MA TRIZ Certification Level 1 Training (Part 2)

I attended MA TRIZ Certification Level 1 Training on 19, 20, 26 & 27 April 2013 which organized by Institute of Systematic Innovation, Hong Kong. I would like to summarize my study below for sharing.

Invention Principle 22 - Convert Harm into Benefit: Sandwich bag had fake mold printed on it to discourage thieves (http://boingboing.net/2008/09/16/sandwich-bag-has-fak.html).

Inventive Principle 24 - Mediator: Use paper ring as mediator to avoid heat of coffee cup.

Inventive Principle 32 - Color Changes: The liquid inside the bulb of fire sprinkler used color code to indicate the different temperature classification.

Inventive Principle 37 - Thermal Expansion: The fire sprinkler worked when bulb broke as a result of the thermal expansion of the liquid inside the bulb.

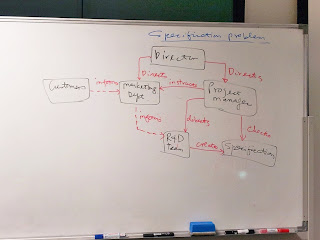

The following diagram showed how to use the Contradiction Matrix.

Dr. Li then introduced how to use Physical Contradiction to solve a problem. Physical Contradictions are some aspects of the product must have two opposing state. Something must increase, the same parameter must decrease. It was formulated for physical parameters which can be resolved in time, space, affiliation, and system hierarchy.

There are three types of methods to solve physical contradictions.

- Separating contradictory demands (included separation in Space, Time, Relation & System Level)

- Satisfying contradictory demands

- Bypassing contradictory demands

Day 4 (27 April 2013)

In the last day of TRIZ training course, Dr. Li introduced Feature Transfer, which was an analytical tool for improvement of the base system by transferring relevant features (say properties, characteristic, etc.) from the alternative system.

After that Dr. Li briefed the Substance-Field Standard Solutions using Substance-Field Model (Su-Field Model). There are 76 generalized model of standard inventive solution which would be included in TRIZ Level 2 training.

The last topic was TRIZ for Patent Strategies. The goal of Competitive Patent Circumvention is to legally circumvent the constraints imposed by competitive patents through applying Function Analysis, Cause Effect Chains Analysis and Trimming. It is at least one subsystem (component) must be removed.

After that we needed to perform project presentation and quiz for examination.

Reference:

MA TRIZ Certification Level 1 Training (Part 1) - http://qualityalchemist.blogspot.hk/2013/04/ma-triz-certification-level-1-training.html

20111202 - Seminar on Introduction to TRIZ - http://qualityalchemist.blogspot.hk/2011/12/seminar-on-introduction-to-triz.html

20111122 - Seminar on Business Excellence with Innovative Improvements - http://qualityalchemist.blogspot.hk/2011/11/seminar-on-business-excellence-with.html

20110413 - HKU Quality Management Student Forum - http://qualityalchemist.blogspot.hk/2011/04/hku-quality-management-student-forum.html

20090822 - Innovation – From Art to Science - http://qualityalchemist.blogspot.hk/2009/08/innovation-from-art-to-science.html

20090614 - Innovation / Creativity Management (BS 7000-1:2008) - http://qualityalchemist.blogspot.hk/2009/06/innovation-creativity-management-bs.html

Institute of Systematic Innovation, HK - http://www.isi.org.hk/

Dr. Michael YH Li (Certified TRIZ Specialist, MA TRIZ Level 3) was our trainer and he introduced the course schedule as follows.

Day 1 (19 April 2013)

- Introduction of TRIZ

- Multi-screen Thinking - The Nine Windows

- Ideality and Ideal Final Result

- Function Analysis

Day 2 (20 April 2013)

- Cause Effect Chain Analysis

- Trimming

- Technical and Physical Contradiction

Day 3 (26 April 2013)

- Technical and Physical Contradiction

- 40 Inventive Principles

Day 4 (27 April 2013)

- Feature Transfer

- Function Oriented Search

- Introduction to Standard Inventive Solution

- TRIZ for Patent Strategies

Day 3 (26 April 2013)

A group photo for all classmates in TRIZ Level 1 was took.

Dr. Li continued to the technical contradiction and briefed 39 generalised parameters. We needed to choose the one which had the closest similar meaning to the specific parameters (Divergent). Then Contradiction Matrix was to select different inventive principle to find the generic solution. After that specific solution was identified through analogical though from generic solution (Convergent)

39 Engineering Parameters were shown in the following table.

Then Dr. Li explained 40 Principles one by one and it showed as following table.

Some examples were showed below.

Inventive Principle 7 - Nesting (Nested Doll): Chair are nested inside chair

- Introduction of TRIZ

- Multi-screen Thinking - The Nine Windows

- Ideality and Ideal Final Result

- Function Analysis

Day 2 (20 April 2013)

- Cause Effect Chain Analysis

- Trimming

- Technical and Physical Contradiction

Day 3 (26 April 2013)

- Technical and Physical Contradiction

- 40 Inventive Principles

Day 4 (27 April 2013)

- Feature Transfer

- Function Oriented Search

- Introduction to Standard Inventive Solution

- TRIZ for Patent Strategies

Day 3 (26 April 2013)

A group photo for all classmates in TRIZ Level 1 was took.

Dr. Li continued to the technical contradiction and briefed 39 generalised parameters. We needed to choose the one which had the closest similar meaning to the specific parameters (Divergent). Then Contradiction Matrix was to select different inventive principle to find the generic solution. After that specific solution was identified through analogical though from generic solution (Convergent)

39 Engineering Parameters were shown in the following table.

Then Dr. Li explained 40 Principles one by one and it showed as following table.

Some examples were showed below.

Inventive Principle 7 - Nesting (Nested Doll): Chair are nested inside chair

Invention Principle 22 - Convert Harm into Benefit: Sandwich bag had fake mold printed on it to discourage thieves (http://boingboing.net/2008/09/16/sandwich-bag-has-fak.html).

Inventive Principle 24 - Mediator: Use paper ring as mediator to avoid heat of coffee cup.

Inventive Principle 32 - Color Changes: The liquid inside the bulb of fire sprinkler used color code to indicate the different temperature classification.

Inventive Principle 37 - Thermal Expansion: The fire sprinkler worked when bulb broke as a result of the thermal expansion of the liquid inside the bulb.

The following diagram showed how to use the Contradiction Matrix.

Dr. Li then introduced how to use Physical Contradiction to solve a problem. Physical Contradictions are some aspects of the product must have two opposing state. Something must increase, the same parameter must decrease. It was formulated for physical parameters which can be resolved in time, space, affiliation, and system hierarchy.

There are three types of methods to solve physical contradictions.

- Separating contradictory demands (included separation in Space, Time, Relation & System Level)

- Satisfying contradictory demands

- Bypassing contradictory demands

In the last day of TRIZ training course, Dr. Li introduced Feature Transfer, which was an analytical tool for improvement of the base system by transferring relevant features (say properties, characteristic, etc.) from the alternative system.

After that Dr. Li briefed the Substance-Field Standard Solutions using Substance-Field Model (Su-Field Model). There are 76 generalized model of standard inventive solution which would be included in TRIZ Level 2 training.

The last topic was TRIZ for Patent Strategies. The goal of Competitive Patent Circumvention is to legally circumvent the constraints imposed by competitive patents through applying Function Analysis, Cause Effect Chains Analysis and Trimming. It is at least one subsystem (component) must be removed.

After that we needed to perform project presentation and quiz for examination.

Reference:

MA TRIZ Certification Level 1 Training (Part 1) - http://qualityalchemist.blogspot.hk/2013/04/ma-triz-certification-level-1-training.html

20111202 - Seminar on Introduction to TRIZ - http://qualityalchemist.blogspot.hk/2011/12/seminar-on-introduction-to-triz.html

20111122 - Seminar on Business Excellence with Innovative Improvements - http://qualityalchemist.blogspot.hk/2011/11/seminar-on-business-excellence-with.html

20110413 - HKU Quality Management Student Forum - http://qualityalchemist.blogspot.hk/2011/04/hku-quality-management-student-forum.html

20090822 - Innovation – From Art to Science - http://qualityalchemist.blogspot.hk/2009/08/innovation-from-art-to-science.html

20090614 - Innovation / Creativity Management (BS 7000-1:2008) - http://qualityalchemist.blogspot.hk/2009/06/innovation-creativity-management-bs.html

Institute of Systematic Innovation, HK - http://www.isi.org.hk/

2013年4月24日星期三

MA TRIZ Certification Level 1 Training (Part 1)

I attended MA TRIZ Certification Level 1 Training on 19, 20, 26 & 27 April 2013 which organized by Institute of Systematic Innovation, Hong Kong. I would like to summarize my study below for sharing.

Dr. Michael YH Li (Certified TRIZ Specialist, MA TRIZ Level 3) was our trainer and he introduced the course schedule as follows.

Day 1 (19 April 2013)

- Introduction of TRIZ

- Multi-screen Thinking - The Nine Windows

- Ideality and Ideal Final Result

- Function Analysis

Day 2 (20 April 2013)

- Cause Effect Chain Analysis

- Trimming

- Technical and Physical Contradiction

Day 3 (26 April 2013)

- 40 Inventive Principles

- Feature Transfer

Day 4 (27 April 2013)

- Function Oriented Search

- Introduction to Standard Inventive Solution

- TRIZ for Patent Strategies

Day 1 (19 April 2013)

In the beginning, Dr. Li introduced The International TRIZ Association (MATRIZ) with 5 levels of certified TRIZ Specialist and briefed the development of TRIZ.

TRIZ is Theoria Resheneyva IsobretateIskehuh Zadach (Theory of Solving Problems Inventively). The father of TRIZ was Genrich Altshuller (1926 - 1998) who was a discovery of a talented patent examiner for the Russian navy.

The innovation Roadmap was separated into three parts including Problem Identification, Problem Resolution and Concept Substantiation. In Level 1 course, we would study the following items: Function Analysis, Cause Effect Chain Analysis, Trimming, Feature Transfer, Function Oriented Search, Contradiction Analysis, Inventive Principles, Su-Field Standard Solutions and Secondary Problem Solving.

Dr. Li mentioned five basic concepts of TRIZ included Functionality, Contradiction, Ideality, Resources and Pattern of Evolution. Then he quoted a statement from Peter F. Drucker (1995) that "Every organization - not just businesses - needs one core competence: Innovation, and ever organization needs a way to record and appraise its Innovative Performance".

During introduction of some successful and failure innovation product. The Segway PT which was a two-wheeled, self-balancing, battery-powered electric vehicle, was mentioned. I have an experience to stand on Segway and took a photo during my EngD Graduate.

Some roadblocks to innovation were discussed such as Historical Mindset, Need for Instant Answers, An Impatient World, Resistance to Change, Change is Threatening, Poorly Defined Problem or Objective, "Not Invented Here" Syndrome, Habits, Past Experiences, Inability to Accept Risk, Peer Influences and Rejection of Past Ideas. But TRIZ would help us to break our Psychological Inertia by seeing things from many different views.

Innovation and Risk diagram demonstrated the higher level of innovation, the likelihood of result was low (indicating risky) but its impact was very high (meaning rewarding if success). There were 5 levels of Invention (with % distribution).

Level 1: Apparent Solution (32%)

Level 2: Minor Improvement (45%)

Level 3: Major Improvement (18%)

Level 4: New Concept (4%)

Level 5: Discovery (1%)

Innovation was not a flash but a connected process. When compared Random methods (e.g. Trial and Error, Brainstorming, etc.) and TRIZ, it was found that TRIZ used patterns and predictive knowledge and structured principles to find out the most ideal ideas in narrower range.

TRIZ process was Analysis Problem, Generation New Ideas and Selection of Best Ideas. TRIZ transferred a specific problem to a general problem and found a general solution.

The 9 Windows model was a tool for multi-screen thinking in Time and Space. Supersystem could be Environment, System was an object and Subsystem was a component.

TRIZ process was Analysis Problem, Generation New Ideas and Selection of Best Ideas. TRIZ transferred a specific problem to a general problem and found a general solution.

The 9 Windows model was a tool for multi-screen thinking in Time and Space. Supersystem could be Environment, System was an object and Subsystem was a component.

At the end of Day 1, Dr. Li introduced Function Analysis. Function definition was stated that "An action performed by one Material Object to Change parameter(s) of another Material Object or Maintain parameter(s) of another Material Object which otherwise the relevant parameters will be changed". There were three stages: Component Analysis → Interaction Analysis → Function Modeling. Using the 9 Windows could identified system, system components and supersystem components. Then it need to use a matrix to identify each components interactions (e.g. "+" in the table means interaction component 1 and component 2. If "-", both components were no interaction.) Function modeling provided a functional representative of an system in a simple words such as CAR (Function Carrier) MOVE (Action) PEOPLE (Object of the Function). The goal of Function Analysis was to clearly identify and evaluation functional advantages and disadvantages of the system.

Day 2 (20 April 2013)

We continued the Function Analysis exercise using different product. During specification problem solving, Dr. Li briefed another business approach using TRIZ which raised by Mr. Darrell Mann (Author, Hands on Systematic Innovation for Business & Management).

Mr. Darrell Mann's Book: Hands on Systematic Innovation for Business & Management

Then Dr. Li introduced Cause and Effect Chain Analysis (CECA). After Function Analysis, it usually identified a large number of disadvantages. Therefore, CECA was employed to identify the Key Disadvantages of the System. It was similar to 5 Why to identify the root cause of the problem from target disadvantage to .key disadvantage.

The last topic in Problem Identification was Trimming. Trimming was based on improving a system by reducing the number of components and simplifying the system to achieve Simplicity Design. There were several objectives of trimming, but not limited to, "Eliminate negative functions", "Reduce cost", "Reduce complexity", "Improve performance / throughput" and "Toward increasing Ideality."

Traditionally, there were 3 trimming rules.

Rule A: Function Carrier can be trimmed if we remove the Object of its useful Function. (X - Remove)

Rule B: Function Carrier can be trimmed if the Object of the Function performs the Useful Function itself (O - Self-service)

Rule C: Function Carrier can be trimmed if another Component performs its useful Function ( ↓ - Substitution by existing System Component)

However, Dr. Li and other experts agreed to add one more rule as follow.

Rule X: Function Carrier can be trimmed if its useful function is no longer needed. ( →x No Action Need)

After Problem Identification, Dr. Li discussed Problem Resolution method entitled "Fuction-Oriented Sarch (FOS). It was a problem solving tool based on identifying existing technologies worldwide, using function criteria. Altshuller said "Some basic functions are the same across different industries for different products". So that FOS borrowed idea (through searching solutions from leading industry) to overcome the limitation.

Some knowledge databases were shown below.

Function Database - http://function.creax.com/

Attribute Database - http://attributes.creax.com/

Patent database - http://www.freepatentsonline.com/

The last topic in Day 2 was Contradictions which included Technical Contradiction, Physical Contradiction and Inventive Principles. Since we believed that "Nothing is perfect", it should have contradiction.

Technical contradiction situation, in which an attempt to improve one parameter of an system leads to the worsening of another parameter. In order to solve technical contradiction, the conflicting parameters are generalized to 39 typical parameters and matching to 40 Inventive Principles using Contradiction Table.

One of method named "IF ... THEN ... BUT" could identified the technical contradiction. For example, IF a mobile is larger, THEN it can display in larger screen, BUT it will be heavier. (Screen Size (+) vs Weight (-))

Genrich Altshuller (translated by Lev Shulyak) (1996) And Suddenly the Inventor Appeared – TRIZ, the Theory of Inventive Problem Solving, Technical Innovation Center, Inc. (and Chinese Version)

Reference:

MA TRIZ Certification Level 1 Training (Part 2) - http://qualityalchemist.blogspot.hk/2013/04/ma-triz-certification-level-1-training_27.html 20111202 - Seminar on Introduction to TRIZ - http://qualityalchemist.blogspot.hk/2011/12/seminar-on-introduction-to-triz.html

20111122 - Seminar on Business Excellence with Innovative Improvements - http://qualityalchemist.blogspot.hk/2011/11/seminar-on-business-excellence-with.html

20110413 - HKU Quality Management Student Forum - http://qualityalchemist.blogspot.hk/2011/04/hku-quality-management-student-forum.html

20090822 - Innovation – From Art to Science - http://qualityalchemist.blogspot.hk/2009/08/innovation-from-art-to-science.html

20090614 - Innovation / Creativity Management (BS 7000-1:2008) - http://qualityalchemist.blogspot.hk/2009/06/innovation-creativity-management-bs.html

Institute of Systematic Innovation, HK - http://www.isi.org.hk/

Dr. Michael YH Li (Certified TRIZ Specialist, MA TRIZ Level 3) was our trainer and he introduced the course schedule as follows.

Day 1 (19 April 2013)

- Introduction of TRIZ

- Multi-screen Thinking - The Nine Windows

- Ideality and Ideal Final Result

- Function Analysis

Day 2 (20 April 2013)

- Cause Effect Chain Analysis

- Trimming

- Technical and Physical Contradiction

Day 3 (26 April 2013)

- 40 Inventive Principles

- Feature Transfer

Day 4 (27 April 2013)

- Function Oriented Search

- Introduction to Standard Inventive Solution

- TRIZ for Patent Strategies

Day 1 (19 April 2013)

In the beginning, Dr. Li introduced The International TRIZ Association (MATRIZ) with 5 levels of certified TRIZ Specialist and briefed the development of TRIZ.

TRIZ is Theoria Resheneyva IsobretateIskehuh Zadach (Theory of Solving Problems Inventively). The father of TRIZ was Genrich Altshuller (1926 - 1998) who was a discovery of a talented patent examiner for the Russian navy.

The innovation Roadmap was separated into three parts including Problem Identification, Problem Resolution and Concept Substantiation. In Level 1 course, we would study the following items: Function Analysis, Cause Effect Chain Analysis, Trimming, Feature Transfer, Function Oriented Search, Contradiction Analysis, Inventive Principles, Su-Field Standard Solutions and Secondary Problem Solving.

Dr. Li mentioned five basic concepts of TRIZ included Functionality, Contradiction, Ideality, Resources and Pattern of Evolution. Then he quoted a statement from Peter F. Drucker (1995) that "Every organization - not just businesses - needs one core competence: Innovation, and ever organization needs a way to record and appraise its Innovative Performance".

During introduction of some successful and failure innovation product. The Segway PT which was a two-wheeled, self-balancing, battery-powered electric vehicle, was mentioned. I have an experience to stand on Segway and took a photo during my EngD Graduate.

Some roadblocks to innovation were discussed such as Historical Mindset, Need for Instant Answers, An Impatient World, Resistance to Change, Change is Threatening, Poorly Defined Problem or Objective, "Not Invented Here" Syndrome, Habits, Past Experiences, Inability to Accept Risk, Peer Influences and Rejection of Past Ideas. But TRIZ would help us to break our Psychological Inertia by seeing things from many different views.

Innovation and Risk diagram demonstrated the higher level of innovation, the likelihood of result was low (indicating risky) but its impact was very high (meaning rewarding if success). There were 5 levels of Invention (with % distribution).

Level 1: Apparent Solution (32%)

Level 2: Minor Improvement (45%)

Level 3: Major Improvement (18%)

Level 4: New Concept (4%)

Level 5: Discovery (1%)

Innovation was not a flash but a connected process. When compared Random methods (e.g. Trial and Error, Brainstorming, etc.) and TRIZ, it was found that TRIZ used patterns and predictive knowledge and structured principles to find out the most ideal ideas in narrower range.

TRIZ process was Analysis Problem, Generation New Ideas and Selection of Best Ideas. TRIZ transferred a specific problem to a general problem and found a general solution.

The 9 Windows model was a tool for multi-screen thinking in Time and Space. Supersystem could be Environment, System was an object and Subsystem was a component.

TRIZ process was Analysis Problem, Generation New Ideas and Selection of Best Ideas. TRIZ transferred a specific problem to a general problem and found a general solution.

The 9 Windows model was a tool for multi-screen thinking in Time and Space. Supersystem could be Environment, System was an object and Subsystem was a component.

At the end of Day 1, Dr. Li introduced Function Analysis. Function definition was stated that "An action performed by one Material Object to Change parameter(s) of another Material Object or Maintain parameter(s) of another Material Object which otherwise the relevant parameters will be changed". There were three stages: Component Analysis → Interaction Analysis → Function Modeling. Using the 9 Windows could identified system, system components and supersystem components. Then it need to use a matrix to identify each components interactions (e.g. "+" in the table means interaction component 1 and component 2. If "-", both components were no interaction.) Function modeling provided a functional representative of an system in a simple words such as CAR (Function Carrier) MOVE (Action) PEOPLE (Object of the Function). The goal of Function Analysis was to clearly identify and evaluation functional advantages and disadvantages of the system.

Day 2 (20 April 2013)

We continued the Function Analysis exercise using different product. During specification problem solving, Dr. Li briefed another business approach using TRIZ which raised by Mr. Darrell Mann (Author, Hands on Systematic Innovation for Business & Management).

Mr. Darrell Mann's Book: Hands on Systematic Innovation for Business & Management

Then Dr. Li introduced Cause and Effect Chain Analysis (CECA). After Function Analysis, it usually identified a large number of disadvantages. Therefore, CECA was employed to identify the Key Disadvantages of the System. It was similar to 5 Why to identify the root cause of the problem from target disadvantage to .key disadvantage.

The last topic in Problem Identification was Trimming. Trimming was based on improving a system by reducing the number of components and simplifying the system to achieve Simplicity Design. There were several objectives of trimming, but not limited to, "Eliminate negative functions", "Reduce cost", "Reduce complexity", "Improve performance / throughput" and "Toward increasing Ideality."

Traditionally, there were 3 trimming rules.

Rule A: Function Carrier can be trimmed if we remove the Object of its useful Function. (X - Remove)

Rule B: Function Carrier can be trimmed if the Object of the Function performs the Useful Function itself (O - Self-service)

Rule C: Function Carrier can be trimmed if another Component performs its useful Function ( ↓ - Substitution by existing System Component)

However, Dr. Li and other experts agreed to add one more rule as follow.

Rule X: Function Carrier can be trimmed if its useful function is no longer needed. ( →x No Action Need)

After Problem Identification, Dr. Li discussed Problem Resolution method entitled "Fuction-Oriented Sarch (FOS). It was a problem solving tool based on identifying existing technologies worldwide, using function criteria. Altshuller said "Some basic functions are the same across different industries for different products". So that FOS borrowed idea (through searching solutions from leading industry) to overcome the limitation.

Some knowledge databases were shown below.

Function Database - http://function.creax.com/

Attribute Database - http://attributes.creax.com/

Patent database - http://www.freepatentsonline.com/

The last topic in Day 2 was Contradictions which included Technical Contradiction, Physical Contradiction and Inventive Principles. Since we believed that "Nothing is perfect", it should have contradiction.

Technical contradiction situation, in which an attempt to improve one parameter of an system leads to the worsening of another parameter. In order to solve technical contradiction, the conflicting parameters are generalized to 39 typical parameters and matching to 40 Inventive Principles using Contradiction Table.

One of method named "IF ... THEN ... BUT" could identified the technical contradiction. For example, IF a mobile is larger, THEN it can display in larger screen, BUT it will be heavier. (Screen Size (+) vs Weight (-))

MA TRIZ Certification Level 1 Training (Part 2) - http://qualityalchemist.blogspot.hk/2013/04/ma-triz-certification-level-1-training_27.html 20111202 - Seminar on Introduction to TRIZ - http://qualityalchemist.blogspot.hk/2011/12/seminar-on-introduction-to-triz.html

20111122 - Seminar on Business Excellence with Innovative Improvements - http://qualityalchemist.blogspot.hk/2011/11/seminar-on-business-excellence-with.html

20110413 - HKU Quality Management Student Forum - http://qualityalchemist.blogspot.hk/2011/04/hku-quality-management-student-forum.html

20090822 - Innovation – From Art to Science - http://qualityalchemist.blogspot.hk/2009/08/innovation-from-art-to-science.html

20090614 - Innovation / Creativity Management (BS 7000-1:2008) - http://qualityalchemist.blogspot.hk/2009/06/innovation-creativity-management-bs.html

Institute of Systematic Innovation, HK - http://www.isi.org.hk/

2013年4月21日星期日

ASQ InfVoices - Hong Kong Quality Awards & Programs

The April Topic of ASQ Influential Voice in Chinese was "Global Quality Programs (Don't Just Call Them Awards)" which initiated by Paul Borawski (CEO, ASQ). I would like to introduce some quality awards in Hong Kong.

Hong Kong Awards for Industry (HKIA) (formerly named Governor’s Award for Industry) was initiated in 1989 by the Hong Kong Government. It was organized by a committee that was chaired by the Director-General of Trade and Industry with membership drawn from trade and industrial organizations and industrial support bodies in Hong Kong. It is the first award scheme in Hong Kong that comprises seven categories of awards. Two of the most important awards in the scheme were the productivity category and the quality category. These were merged in 2005.

Hong Kong Awards for Industry (HKIA) - Productivity and Quality criteria are reference to Malcolm Baldrige National Quality Award (MBNQA).

Another famous quality award in Hong Kong was organized by Hong Kong Management Association (HKMA) on 1991. Moreover, it criteria was also reference to MBNQA.

Both HKIA-P&Q and HKMA-QA performed annually. Another non-regular award in Hong Kong had Quality Control Circle Award (QCCA) which was organized by Hong Kong Quality Management Association (HKQMA) through biannual Hong Kong Quality Circles Convention. In 2009, HKQMA and Macau Quality Management Association (MQMA) co-organized the QCCA.

Although Hong Kong Society for Quality (HKSQ) hadn't arranged quality award, we had started the earliest Quality Management Student Project Competition since 1994. HKSQ recognizes the value of continuing the meaningful event as a vehicle to further the interest of final year undergraduates in quality management and to emphasize its importance and relevance to local industry. Until 2005, we changed the competition style from final year project to company based project(named HKSQ Company Based Student Project Competition). It aimed to offer an opportunity for students to work on an actual industrial case and propose resolution.

In my opinion, quality awards in Hong Kong did not become a continuous quality program. It is only one-stop recognition. Winners would maintenance their existing system and continual improvement, but they are not specific to review quality award criteria regularly. As I known, only Housing Department and Phillips (Hong Kong) employed EFQM model continuously. Housing Department is planning to seek for EFQM Excellence Awards but Phillips (Hong Kong) had stopped the program few year ago.

On the other hand, HKSQ Company Based Student Project Competition is more significant to educate the students understanding the real industrial problem and working environment. We seek for different industrial sponsor both company visit support and prizes annually. The follow photo was taken in front of TTI during factory visit in 2013.

Reference:

Hong Kong Awards for Industry (HKIA) - http://www.hkindustryaward.org/

HKMA - Quality Award - http://www.hkma.org.hk/qa/front.htm

QCC Award - http://www.mss-mllc.com/mqma/QCC.html

HKSQ Quality Management Student Project Competition - http://www.hksq.org/quality_management_competition.htm

HKSQ Company Based Student Project Competition - http://www.hksq.org/company_based_competition.htm

EFQM Excellence Awards - http://www.efqm.org/en/tabid/166/default.aspx

Hong Kong Awards for Industry (HKIA) (formerly named Governor’s Award for Industry) was initiated in 1989 by the Hong Kong Government. It was organized by a committee that was chaired by the Director-General of Trade and Industry with membership drawn from trade and industrial organizations and industrial support bodies in Hong Kong. It is the first award scheme in Hong Kong that comprises seven categories of awards. Two of the most important awards in the scheme were the productivity category and the quality category. These were merged in 2005.

Hong Kong Awards for Industry (HKIA) - Productivity and Quality criteria are reference to Malcolm Baldrige National Quality Award (MBNQA).

Another famous quality award in Hong Kong was organized by Hong Kong Management Association (HKMA) on 1991. Moreover, it criteria was also reference to MBNQA.

Both HKIA-P&Q and HKMA-QA performed annually. Another non-regular award in Hong Kong had Quality Control Circle Award (QCCA) which was organized by Hong Kong Quality Management Association (HKQMA) through biannual Hong Kong Quality Circles Convention. In 2009, HKQMA and Macau Quality Management Association (MQMA) co-organized the QCCA.

Although Hong Kong Society for Quality (HKSQ) hadn't arranged quality award, we had started the earliest Quality Management Student Project Competition since 1994. HKSQ recognizes the value of continuing the meaningful event as a vehicle to further the interest of final year undergraduates in quality management and to emphasize its importance and relevance to local industry. Until 2005, we changed the competition style from final year project to company based project(named HKSQ Company Based Student Project Competition). It aimed to offer an opportunity for students to work on an actual industrial case and propose resolution.

In my opinion, quality awards in Hong Kong did not become a continuous quality program. It is only one-stop recognition. Winners would maintenance their existing system and continual improvement, but they are not specific to review quality award criteria regularly. As I known, only Housing Department and Phillips (Hong Kong) employed EFQM model continuously. Housing Department is planning to seek for EFQM Excellence Awards but Phillips (Hong Kong) had stopped the program few year ago.

On the other hand, HKSQ Company Based Student Project Competition is more significant to educate the students understanding the real industrial problem and working environment. We seek for different industrial sponsor both company visit support and prizes annually. The follow photo was taken in front of TTI during factory visit in 2013.

Reference:

Hong Kong Awards for Industry (HKIA) - http://www.hkindustryaward.org/

HKMA - Quality Award - http://www.hkma.org.hk/qa/front.htm

QCC Award - http://www.mss-mllc.com/mqma/QCC.html

HKSQ Quality Management Student Project Competition - http://www.hksq.org/quality_management_competition.htm

HKSQ Company Based Student Project Competition - http://www.hksq.org/company_based_competition.htm

EFQM Excellence Awards - http://www.efqm.org/en/tabid/166/default.aspx

訂閱:

文章 (Atom)