The first day of Asian Network for Quality (ANQ) Congress 2017 in Soaltee Crowne Plaza Hotel, Kathmandu, Nepal was held on 20 Sep 2017. The

congress theme was “Quality Culture for Sustainable Prosperity”. Before the

congress, Minda and I took a photo in front of the entrance.

During

registration, I met Mr.

Janardan Ghimire (President, NQPCN) and Mrs. Bindu Manandhar (EC member, NQPCN). We took a photo for memory.

Minda helped the registration affairs for Hong Kong Society for Quality (HKSQ) members.

In the

congress hall, we took a group photo with Prof. Kano, CAQ, CSQ, SQI, SQAT and

HKSQ.

HKSQ group

(5 representatives) photo was taken during the congress.

(Left:

Dr. Inez M Zwetsloot (CityU), Dr. KS Chin, Mr. Peter Fung, Ms. Minda Chiang and

I)During the opening of ANQ Congress 2017, a Nepal traditional performance included music and dancing were performed. (See short video below)

Plenary Session 1: Opening of Congress

In the beginning, Mr. Janardan Ghimire (President, NQPCN) gave

a welcome speech and he would like to extend a warm welcome to all

distinguished guests and delegates at Kathmandu, the resilience valley of the

Himalayas and capital of Nepal. The congress would focus on sharing novel ideas

on crucial quality culture, issues and trends on the theme of “Quality Culture

for Sustainable Prosperity”.

Inauguration

by Chief Guest – Hon. Minister, Sunil Bahadur Thapa (Minister of Industry) to

lighting the Panas.

Then Prof.

Azat Abdrakhmanov (President, ANQ) gave an opening speech and briefed ANQ way

to all participants.

Chief

Guest speech was performed by Hon. Minister, Sunil Bahadur Thapa (Minister of

Industry) and he said QC in products and services were important. This morning we would learnt the best

practices that could be better live and better quality in different parties

such as supply chain. Quality Culture in

prosperity we got good

experience for Nepal through ANQ Congress.

The

first keynote speaker was Prof. Noriaki Kano (Honorary Chairperson, ANQ) and

his presentation topic entitled “Service Quality Management in the New Era”. Firstly, he suggested Nepal should stop

manufacturing and focused on service industry because of sandwich by the two

gigantic countries (China and India) and god bless with Himalaya. Moreover, he suggested changing time zone

(UTC) to India time or Bangladesh time so as to convenient for tourists.

Prof.

Kano reviewed his book “TQM in Service Industries” which had published about 30

years ago. Some cases studies of TQM

implementation in the service sector included resort hotel, electric power

company, retail store, after-sales service company, financial institution,

trading company, etc. Then Prof. Kano

analyzed the growth of service industries in Asia and classification of service

industries. He said the top four GDP

growth service industries in Japan from 1970 to 2015 were “Health / Sanitation

/ Social Welfare”, “Information / Communication”, “Expert / Scientific /

Technical Services” and “Wholesale / Retailer”.

After

that Prof. Kano told us the three activities elements of TQM in Service

Industries and they were Humanware (people’s work), hardware (building,

equipment, measurement tools, etc.) and software (system, IT, ICT, etc.) He also raised an example of lodging service

(hotel) as follows:

Hardware (H/W): guest room, bathroom, TV, telephone, safety

box, etc.

Software (S/W): price system, check-in/out time, morning

call, laundry service system, directory, restaurant menu, etc.

Humanware (Hmn/W): housekeeping a guestroom, room

service operator response, manner of staff at check-in/out, behavior of

waiter/waitress, etc.

Finally,

Prof. Kano discussed the different concepts on products and services between

1980s and the New Era. In new era, on

time delivery was very essential for servicing.

Hmn/W focused servicing or for tailor-made services, the flexibility or

the ability to adapt to specific circumstances (awareness, observation, and

attention), on-the-spot customization and thinking ahead was required. Lastly,

Prof. Kano concluded that “Service Quality is not only dependent on humanware

but also hardware and software.

Therefore, the application of process management and control by data

that was considered difficult will be popular in TQM promotion in

servicing. The gap between service

quality management and product quality management will be reducing with the

lapse of time.”

At the

end, I asked a question that what is different between peopleware and

humanware. Prof. Kano replied that was

the same. However, I thought that the

coverage of humanware should be larger.

Prof.

Azat Abdrakhmanov

and Mr. Janardan

Ghimire presented an appreciation certification to Prof. Noriaki Kano.

During

the tea break, I took many photos with ANQ friends for memory.

Photo of HKSQ and CAQ

(Left: Dr. KS Chin, Ms. Wang (王麗林), Prof. Tang Xiaoqing (唐曉青) (Vice-chairperson, CAQ), I and Dr. Inez M Zwetsloot)

WACQ

group photo included CAQ, CSQ, SQI and HKSQ

(Left:

I, Liu Xiaosong, Mr. Kenneth Liang, Ms. Wang, Prof. Ching-Chow Yang (楊錦洲), Mr. Tan Gheng Een, Prof.

Kuan Sheng-Pin (官生平), Dr. KS

Chin and Mr. Han Ling (韓岭) (Sr. Manager, International Exchange Department, CAQ))

I took a photo with Prof. Dinesh P. Chapagain (Founder President and Advisor of NQPCN, Nepal)

(Left: Mr. Too Meng Ken (SQI), Dr.

Thanakom Soontornchainacksaeng, Dr. Panisuan Jamnarnwej (SQAT), I, Prof.

Phulporn Saengbangpla (SQAT), Dr. Yury Gusakov (ROQ) and Ms. Gulbakhram Aitkhozhina (ROQ))

Minda

took a photo with Prof.

Phulporn Saengbangpia (Honary Advisor, SQAT) (HK gift - Moon cake)

Photo

with Mr. Janak Mehta (ISQ)

Photo

with Prof. Sung Hyun Park (KSQM)

Then we

went for a coffee.

I took a

photo with Ms. Wang and Mr. & Mrs. Kuan.

Minda

and I took a photo with Prof. Kano.

Then I

took a photo with Nepal’s friends.

I also

met two of IAQ friends and took photos for memory again.

Photo

with Mr. J. Ravikant (Associate Vice President & Head TQM, SRF)Photo with Mr. Anil Sachdev (President, TQMI)

Photo

with Prof. Uk Jung (Professor, Operations Management School of Business,

Dongguk University)

Plenary Session 2:

The second

key speaker was Prof. Azat

Abdrakhmanov (President, ANQ) and his presentation topic named “Global risks

and threats – how the Quality will allow us to overcome them”. In the beginning, Prof. Azat pointed out many

threats, crises and challenges in the modern world such as wars, regional

conflicts, uncontrolled migration, economic crises, unemployment, poverty,

ecological and technologic catastrophes, globalization and social negative

factors, etc. He said Quality Management

as a philosophy could prevent or reduce some negative consequences of many of

threats and challenges.

Prof.

Azat also mentioned some benefits of globalization included Foreign Direct

Investments (FDI), Technological Innovation and Economies of Scale

effects. On the other hand, it had some

risks of globalization included Interdependence, National Sovereignty and Equity

Distribution. Then He quoted the Global

Risks Report 2016 and Global Risks Interconnections Map 2016.

Prof.

Azat explained the role of Quality Management in the current environment and

quoted Henry Hazlitt “reveals that economics and ethics are, in fact,

intimately related. Both are concerned

with human action, human conduct, human decision, human choice …” After that

Prof. Azat introduced new approach to strengthening organizational culture

through the four parts of model and they were “Actions of Funders or Leaders”, “Culturally

Consistent Rewards”, Aligning Artifacts” and “Selecting and Socializing

Employees”.

Finally,

Prof. Azat discussed new business concepts included business excellence model

(EFQM and MBNQA), Innovations and benchmarking, as well as Sustainable

development, etc. Lastly, he concluded

that we were not able to exclude crises and threats from our lives. Therefore, we should be prepared for them (risk

management) to reduce or avoid negative consequences. ANQ as an Organization which united National

Quality Organizations had defined “ANQ Way” – its goal is to improve the

quality of life of the population in all Asia Region and in each of our

countries.

The

third key speaker was Mr. Janak Mehta (Chair, IAQ) and his topic entitled “IOT

as Enabler for creating Quality Culture and Sustainable Prosperity”. Firstly, Mr. Mehta aligned his talk with the

theme that Quality Culture is a way of life for benefit of all included Respect

humanity, Fact based, Self-discipline and Customer focused; Sustainable

Prosperity – over a long period of time that long term prosperity rather than

short term profit, benefit for all stakeholders and all living beings.

Then he

mentioned some key issues for Quality Improvement and those key issues were

related to data. (e.g. Reliability of data, Time taken to collect data, real

use conditions data, errors in transmission of data, etc.) Such data could be

gathered in real time, in large numbers and accurately that enable quality

professionals and problem solvers to achieve much higher level of improvement

in shorter time.

After

that Mr. Mehta shared a case study “Intangles – Proprietary Design &

Technology”. Based on the customer

requirement study and identification, the company employed IoT to perform “Predictive

vehicle health monitoring”, “Fuel monitoring”, “Driving Behavior Analysis”, “Vehicle

Tracking”, etc. Company performed extensive study to understand customer pain points

and through IOT specialist to develop hardware, software and algorithm for data

collection, analysis, validation, etc.

At the

end, Mr. Janak Mehta concluded that role of Quality Professional should

understand the key issues and pain through interaction with the customer

through on site, in field observations.

Technology team needed to develop the hardware and the software to

capture the data, analyzed and presented in easily understandable way like a

dash board. Lastly, to use the

information generate and help the customer to overcome technical and operational

issues through structured improvement process.

The Ishikawa-Kano (IKA) award 2017 winner was Mr. Qin Yufeng (President Dong EE Jiao Corporation Limited, PRC). He has more than 30 years’ solid experiences in manufacturing industry, specifically the traditional Chinese medicine industry. Qin has demonstrated significant achievement and advancement in quality discipline by developing and implementing a successful supply chain based quality control mechanism and an innovative GAP traceability system.

Another IKA winner was Mr. Segey Katyrin (President of Russian Chamber of Commerce and Industry (CCT)). He has over 25 years’ experience in the Chamber of Commerce and Industry of Russian Federation. He is taking active part in development of the new Russian Federal law of “On Standardization in Russian Federation” and initiated the inclusion of special article on quality into draft Federal Law “One development of agriculture in Russian Federation”. Mr. Katyrin’s main contribution to quality is in the policy making area at macro level. Since Mr. Katyrin was not able to join the congress, Dr. Yury Gusakov (Senior VP and CEO, ROQ) represented him to get the award.

During the lunch time, we took a group photo and with India friends Mr. J. Ravikant (Associate Vice President & Head TQM, SRF) (Left) and Mr. Neeraj Chandna (Vice President TQM, SRF)

I met IKA award 2017 winner Mr. Qin Yufeng and took a photo for memory.

I took photo with Singapore friends.

I also met Vietnam friends Dr. Pham Xuan Thu (Dean-Business Administration School, College of Foreign Economic Relations) and Ms. Le Thi Giang Phuang.

Technical Session – I (Parallel Session I)

I joined

the parallel session I for Six Sigma.

The

first speaker was Mr. Too Meng Ken (Lecturer, SQI) and his presentation topic

entitled “Improvement of Credit Risk Management in the Mining Industry through

Lean Six Sigma Methodology”. Firstly,

Mr. Too introduced the products of that mining industry included Iron Ore,

Copper, Diamond, Coal, Platinum and Nickel.

Then he briefed the marketing risk management strategy included Market

Risk and Credit Risk.

Mr. Too

employed Lean Six Sigma to handle Credit Risk using DMAIC six sigma approaches and included Lean for

improvement stage. In define phase, Mr.

Too showed us some operational definition of key terms such as Near Miss due to

human error, minor incident and inadequate processes or systems which were

corresponded to Credit Breach (Breach of any defined authorizations, Major

incident and Material financial consequences).

The goal statement was to reduce lead time in invoice booking and cash

application by 50% from baseline 2015.

They achieved to reduce credit limit breaches to zero by April

2016. Finally, value stream mapping was

employed for future state.

The

second speaker was Dr. Inez M Zwetsloot (Asst. Professor, SEEM, CityU) and her

topic was “Lean Six Sigma meets Data Science – Integrating two approaches based

on 3 case-studies”. There were four

elements of Lean Six Sigma (LSS) to establish continuous improvement included “Parallel-meso

structure”, “Improvement specialist leads the project”, “Structured roadmap

called DMAIC” and “Improve performance metrics”.

Dr. Inez

also described that “Data science is utilizing large data sets to provide

insights”. She found the differences

between data science LSS and the traditional elements of LSS.

Therefore,

she modified LSS framework in order to facilitate data science such as

including data scientists in organizational structure & teams, cross train

data scientists and black belts, as well as, allow for iterations in DMAIC

structure.

During

Q&A discussion, Dr. KS Chin suggested SSBB should learn some knowledge

about data science so as to better fusion of LSS and Data Science.

The

third speaker was Mr. Yao-Chang Wang (Unimicron Technology Corp. (Taiwan)) and

his presentation subject named “Build up AOI Trace Nick (O4) Defect Improvement”.

Mr. Wang briefed Unimicron which was one of world leading PCB companies. Then he introduced Flip Chip Ball Grid Array

(FCBGA) which was between IC and PCB to avoid IC damage causing by PCB

warping. Fine Line Space (FLS) was an

ultra-fine pitch circuit smaller than 50 um produced by Lithography –

Semi-Additive Process (SAP).

Mr. Wang’s

studied based on three hypotheses that would impact the process flow. Then he did the potential cause verification

for defects. He concluded the project utilized

six sigma methodologies to find out the critical factors. After screening out the potential causes, the

key factors for clean roller material properties were determined and

improvement actions were implemented.

They reduced O4 defect rate from 1.78% to 0.22% (Target <1.0%).

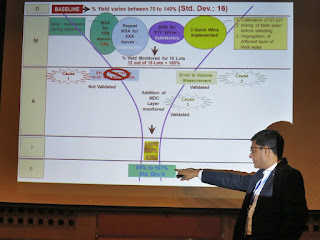

The fourth speaker was Mr. Deepak Bansal (TQM International Pvt. Ltd., India) and his presentation topic was “Business Transformation through Application of Lean Six Sigma in a Bulk Drug Pharmaceutical Company”. Mr. Bansal briefed the company in the field of Phytochemicals over 1000 employees worldwide with three manufacturing sites across India. The managing director decided to go for “Business Transformation” with LSS in three phase approach which was Pilot -> Expansion -> Replication.

LSS

approach followed the framework DMAIC was described by Mr. Bansal. In Pilot

phase, monetary gains were not calculated and declared just to ensure that

employees did not treat this initiative as a cost saving initiative but as a

strategy for Business Transformation. In

Expansion phase, Governance structure was put into place with dedication team

(contain 1 Black Belt and 2 Green Belts).

QA projects were mainly on the theme of variation reduction in testing

(e.g. using MSA) and Financial gains were now calculated. Employees then were

proposing the projects rather than senior people allocating the project that

changed from “Push to Pull” DNA of the company.

NQPCN

representative presented the appreciation certificate to Mr. J. Ravikant (Associate Vice

President & Head TQM, SRF) for servicing as session chair.

Technical Session – II (Parallel Session II)

I

serviced as session chair in Performance Management (PMT) session.

The

first speaker was Ms. Youngju Park (PhD Candidate, Graduate School of Business,

Soongsil University) and her topic named “A Study on the Decisive Factors of

Productivity of Global Mobile Telecommunications Operators”. She introduced the objectives of her studies

included efficiency analyzed the world’s main mobile carriers, finding measures

for efficiency increase of Korea’s mobile carriers and analyze the relative

change in productivity of mobile carriers.

She employed the Malmquist Productivity Index (MPI) by Fare et al. (1994)

for her study.

Ms. Park

concluded S. Korea, Republic of South Arica and Argentina that had high

technical advancement but low the operation efficiency for productivity

improvement. So S. Korea’s speed of

technical advancement from 2G to 4G should increase but large marketing cost

needed to expanse (means large deadweight loss). During Q&A session, I asked when S. Korea

had 5G. She consulted by her teacher and

replied that it may be in 2020.

The

second speaker was Mr. Yukihiro Ando (TQM Consultant, Japanese Society for

Quality Control) and his topic entitled “Introduction to Guidelines for Policy

Management JSQC-Std 33-001(E): 2017”. He

said there was a standard for “Policy Management” as JIS Q 9023:2003. During development of this Guideline, it had

been adapted as JIS Q9026:2016.

Then Mr.

Ando introduced the whole set of relevant JSQC standards. Policy Management is “Activities to achieve

policies by unity of purpose and priority approach with engagement of all

functions and levels”. And Policy is defined as “Overall intentions and

direction of an organization, formally expressed by top management, relating to

achievement of mission, principles, vision and mid-and-long-term business plan

of organization”. (JSQC-Std. 00-001:2007)

After

that Mr. Ando briefed the key concepts of policy management included three

streams of policy management, various types of PDCA cycles and founding

principles. The structure of the

standard was mentioned.

During

Q&A, Minda asked any case about “6.5 - Mental attitude as a manager” for

sharing. Mr. Ando shared that manager

should define the objectives of today to achieve company policy.

The

third speaker was Mr. Wichaya Phanidanant (SCG Packaging Co., Ltd. Thailand)

and his presentation topic was “Sheet Break Reduction in Siam Nippon Paper

Industry”. Firstly, Mr. Phanidanant

introduced his company’s products included Printing, Packaging and Industrial

use paper. There was a challenge for

paper making that the sheet break loss time was the obstacles to increase the

speed of machine (productivity).

Mr.

Wichaya Phanidanant presented the definition of the problem and followed the

sequence from Observation, Analysis, Action, Check, Standardization and Result

to present his project. Finally, they

solved the problem and increase the productivity.

Prof.

Sheng-Pin Kuan (CSQ / QKC-Quality Knowledge Community, Taipei) was the fourth

speaker and his presentation topic named “What Roles can Quality Organizations

play under “One Belt One Road” Initiative”.

He quoted that somebody said “The 21st century will be the

century of China” and it seems true. “One

Belt One Road (OBOR)” is a grand scheme for knitting a network of roads, ports,

railroads and other links from East China through Southeast and South and

Central Asia to Europe. It actually is

century engineering!

Then

Prof. Kuan quoted Dr. Sun Yat Sen statement to explain that we needed to follow

the trend. So that ANQ would consider the trend and think our role under OBOR

initiative.

Lastly,

Prof. Kuan purposed each member of ANQ should have a role in OBOR Economic

Corridors. Moreover, he suggested the

quality activities organized by government organization, nonprofit

organization, profit organization in each economic corridor and such activities

included “Public Service TQM”, “Excellent Performance Management”, “Sustainable

Management System”, “Continual Improvement Mechanism”, “Quality Professional

Training and Certification” and “Product Reliability and Safety Certification”. Therefore, we could form Global Platform for

Quality. At the end, Prof. Kuan used a

news “Nepal signs mega hydro project deal with Chinese firm” as conclusion that

organization members of ANQ should take into account on OBOR.

I as

session chair presented the speaker certificate to Prof. Sheng-Pin Kuan.

The last

speaker of this session was Mr. Amit Patnaik (Senior Manager, Planning &

Scheduling – Steel & HR, KPO, Flat Products Planning, TATA Steel Limited)

and his presentation was “Planning and Scheduling System Tata Steel

Kalinganagar (TSK)”. Firstly, Mr.

Patnaik briefed Tata Steel India operation since 1907. Annual crude steel capacity across Indian

operations was nearly 13 MnTPA with a turnover of US $7889 Mn in FY 2017. Their vision was “We aspire to be the global

steel industry benchmark for Value Creation and Corporate Citizenship”.

Then Mr.

Patnaik introduced the overall supply chain system design of TSK from “order

logging” to “manufacturing execution system (MES)”. He proposed two solutions (Part 1 & 2) in

different position of the supply chain. The solution separated into three parts

and they were Business Process, Design Six Sigma (DSS) and Experience. He

concluded that the key KPI improved in Plan Compliance, Slab Inventory, Average

Edging and Lead Time.

At the

end of this session, Mr. Dipesh Shrestha (Executive Member, NQPCN) presented

the appreciation certificate to me for the session chair contribution.

Technical Session – III (Parallel Session

III)

My

presentation was in Quality and Innovation (QIN) session. Since I needed to

join IAQ dinner, I reschedule my presentation to be the first speaker. My presentation topic entitled “Quality

Innovation – Introduction of Extenics and Integrated System Approach”. In the

beginning, I explained the different about “Quality & Innovation”, “Quality

Innovation” and “Innovation Quality”.

Then I

reviewed the history of Quality and Innovation development and tools. For innovation, it mainly started from Trial

& Error to Brainstorming. The

breakthrough was TRIZ at 70 years ago. However, the actual innovation theory

for solving contradiction I found was “Extenics” at 33 years ago.

After

that I introduced Prof. Cai Wen (蔡文) (Founder of Extenics and The Director of

International Academy of Extenics (HK)) who started his study on 1976 and

published his first paper named “Extension Set and Incompatible Problem” in

1983. He employed formal model to

research the extension possibility of things and then used to solve

contradictory problems.

I had

studied “Extenics” for one year and followed Prof. Cai Wen’s train-the-trainer

class for 12 days in April and May 2017.

I understood the theory behind and discovered how clever Prof. Cai

is. The Extension Set was the core of

the Extencis and Prof. Cai only added the transformation part (in red color) in

the Set theory equation.

Then I

introduced the “Basic-element” which included Matter-element, Affair-element

and Relation-element. I used “Stack” as

example which was my exercise in the training.

The

Conjugate Analysis was one of important concepts in the Extenics. It viewed anythings into four dimension and

they were “Physical (Nonmaterial Part vs Material Part)”, “Systematic (Soft

Part vs Hard Part)”, “Dynamic (Latent Part vs Apparent Part)” and “Antithetic

(Negative Part vs Positive Part)”.

Finally,

I proposed the Integrated Approach for three key innovation methodology and

they were TRIZ (RUSSIA), Extenics (CHINA) and Innovation Culture (USA).

At the end, I used my company case for service innovation using Extenics. One of our projects named Quality Startup Scheme was implemented.

Dr.

Thanakom Soontornchainacksaeng (Asso. Professor, Department of Mechanical and

Aerospace Engineering, Faculty of Engineering, King Mongkut’s University of

Technology North Bangkok) was this session chair and presented a speaker

certification to me.

Reference:

Asian Network for Quality (ANQ) - http://www.anforq.org/

20170918:

ANQ-CEC Meeting 2017 in Nepal - https://qualityalchemist.blogspot.hk/2017/09/anq-cec-meeting-2017-in-nepal.html

20160920:

ANQ Congress 2017 Kathmandu, Nepal – Day 1 - https://qualityalchemist.blogspot.hk/2017/09/anq-congress-2017-kathmandu-nepal-day-1_20.html

20160921:

ANQ Congress 2017 Kathmandu,

Nepal – Day 2 -

https://qualityalchemist.blogspot.hk/2017/09/anq-congress-2017-kathmandu-nepal-day-2.html

20160921:

ANQ Congress 2017 Kathmandu, Nepal – Gala

Dinner - https://qualityalchemist.blogspot.hk/2017/09/anq-congress-2017-kathmandu-nepal-gala.html

沒有留言:

發佈留言