The Seminar named "Common

Findings related to Management Requirements for Medical Testing Laboratories"

was organized by the Hong Kong Accreditation Service (HKAS) on 2 Jun 2017. Ms. Bella Ho (Senior Accreditation Officer,

HKAS) hold the open forum and then Dr. Alex Chan (Accreditation Officer, HKAS)

was the speaker for discussing the assessment findings.

It covered two parts. The first part was open forum to discuss the

issues encountered in implementation of the management requirement in ISO

15189. The second part was data analysis

to show the common assessment findings on management requirement. Bella

explained why we had this seminar because of many enquiries on internal auditor

training. However, HKAS did not provide

such training but they could share the findings for learning purpose.

A) Part 1: Open Forum

Firstly, Ms. Bella Ho briefed the

overall management requirements and then pointed out the most common findings

in each clause.

4.1 Organization and management responsibility

She said most contingency plan

and drill were related to safety but not the business/service viewpoint such as

referral laboratory’s capability and capacity.

Another common missing point was the meeting minutes to be circulated.

4.2 Quality management system

Not following documented

procedures was belong to 4.2.1 (QMS applicable throughout the laboratory)

4.3 Document control

There were 25 out of 33 (75.7%)

accredited laboratories to have no external documents on their master document

list and some were on the list but not all (e.g. ISO 8655 pipette standard).

4.4 Service agreements

4.5 Examination by referral laboratory

Some referral labs used did not

on the updated lists.

4.6 External services and supplies

Documented procedure to select

and purchase external services, equipment that should be able to provide

metrological traceability.

4.7 Advisory services (Communicating with users)

4.8 Resolution of complaints (usually no complaint)

4.9 Identification and control of NCs

4.10 Corrective action

It was found that most CARs were

not monitoring their effectiveness.

4.11 Preventive action

Laboratories had done but no

recorded.

4.12 Continual improvement

Improvement activities shall be

directed at high risk areas. It could

consider to monitoring Quality Indicator (e.g. EQA)

4.13 Control of records

Common missing records in both

management records and technical records such as in-house preparation, operator

traceability, reagent lot number, reference equipment ID on PM record, etc.

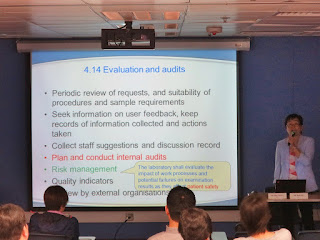

4.14 Evaluation and audit

She said many risk management /

assessment were focused on staff.

However, the laboratory shall evaluate the impact of work processes and

potential failures on examination results as they affect Patient Safety.

Another common finding related to

plan and conduct internal audits was confusing concept of horizontal audit (HA)

and vertical audit (VA). The following

diagram explained clearly the different between them.

For vertical audit report, you

could find the information included sample(s), its type, test method, operator,

date, etc.

For horizontal audit report, you could

exam different people followed the same practice or SOPs.

Then Bella suggested how to select

report for internal audit and then shared some report samples for discussion.

4.15 Management review

Most findings in management

review were staff suggestions and circulation of minutes.

B) Part 2: Common assessment findings on management requirement

Dr. Alex Chan was held the part 2

for Data Analysis.

Firstly, he showed the summary of

assessment number from Oct 2014 to May 2017.

Totally, there were performed 96 assessments.

The overall NCs distribution was

demonstrated in the following pie chart.

The Six most frequency findings

clauses related to management requirement were (1) Document control, (2)

Evaluation and audits, (3) Quality management system, (4) Control of records,

(5) Organization and management responsibility and (6) Use of HKAS

accreditation symbols & claims of accreditation status.

No. 1 –

4.3 Document control

Most documents were not reviewed

in the past 12 months; external documents were not included in the master

list. Posted instructions were not dated

and signed.

No.2 – 4.14

Evaluation and audits

Internal audit no timeframe and

responsible person, as well as did not give sufficient details on the auditing

procedures. Recurrence of a number of

NCs indicated in the last HKAS assessment.

Horizontal audit report coverage was not sufficient and Vertical audit

report was lack of sample ID recording.

Internal audits were conducted by untrained staff. Quality indicators were no target achievement

documented and no monitoring plan.

No.3 – 4.2

Quality management system

Quality manual had not been

updated. No documented policies and

procedures addressing several new requirements in ISO 15189:2012 (e.g. risk

management, staff suggestions, and review by external organizations, etc.)

No.4 – 4.14

Control of records

The system to control records to

maintain traceability required improvement.

The spill kits were said to be checked every month but no record. Record of the HEPA filter leakage test of a

biosafety cabinet was not retrievable during assessment.

No.5 – 4.1

Organization and management responsibility

The Code of Conduct document was

not in detail. Constantly worked

overtime indicated lack of staff resources seriously. Measurable quality objectives had not been

documented. A Quality Policy is not

evident. Quality manager did not report

to the laboratory management at the level at which decisions is made on

laboratory policy, objectives and resources.

No.6 –

Use of HKAS accreditation symbols & claims of accreditation status.

Alex

shared the one and only one critical NC that non-accredited status was not

indicated in the accredited test reports.

Similar finding had been reported in the last assessment.

Another significant NC was that

HOKLAS endorsed reports issued included results of non-accredited examination

only. Some minor NC was about laboratory

webpage was not updated scope of accreditation.

He suggested to link with HOKLAS directory of that laboratory.

Reference:

20160909: HOKLAS Assessment

Feedback Seminar for Medical Testing Laboratory 2016 - https://qualityalchemist.blogspot.hk/2016/09/hoklas-assessment-feedback-seminar-for.html

20150706: HKCTC & HKAS

Seminar on R&D Projects of Medical Testing - https://qualityalchemist.blogspot.hk/2015/07/hkctc-hkas-seminar-on-r-projects-of.html

20130611: HKAS First Assessment

Feedback Seminar for MedLab under ISO 15189 - https://qualityalchemist.blogspot.hk/2013/06/hkas-first-assessment-feedback-seminar.html

20130327: HKAS Seminar of the

Transition Arrangement ISO 15189_2012 - https://qualityalchemist.blogspot.hk/2013/04/hkas-seminar-of-transition-arrangement.html

20130321: Briefing on the New

Edition of ISO 15189:2012 Medical Laboratory - https://qualityalchemist.blogspot.hk/2013/03/briefing-on-new-edition-of-iso.html

20110231: Seminar - The Meaning

of Accreditation to Medical Testing - https://qualityalchemist.blogspot.hk/2011/01/seminar-meaning-of-accreditation-to.html

20101201: Medical Laboratory QM

Training - ISO 15189 - https://qualityalchemist.blogspot.hk/2010/12/medical-laboratory-qm-training-iso.html

20100727: Common nonconformities

encountered in assessments using ISO 15189 - https://qualityalchemist.blogspot.hk/2010/07/common-nonconformities-encountered-in.html

沒有留言:

發佈留言