Hong

Kong Productivity Council (HKPC) established an “Inno Space” on 27 Oct 2017 to

promote the translation of innovative and technological ideas into industrial

designs or products, nurture a start-up culture in Hong Kong and support “re-industrialization”.

The “Inno Space” would provide workspace and technical support to enable users

to develop their innovative ideas into industrial design which may subsequently

be translated into products though prototyping.

TecONE arranged Inno Space visit and sharing seminar on 12th

Jan 2018. I took a photo in front of the

Inno Space for memory.

In

the beginning, Ms. Stephanie Huang (Centre Manager, Inno Space, Corporate

Development of HKPC) gave a welcome speech and introduced Inno Space to us.

Mr.

Chuck Fung (Senior Consultant, Smart Manufacturing & Materials, HKPC) was

the speaker and his presentation entitled “Inno Space and Prototyping Technical

Sharing”. Firstly, he briefed some

technology background and then shared three real cases employed HKPC

technologies to assist industries.

Mr. Fung said there were five technologies types included Optic, Mechatronic, Electronic, Magnetic and Chemistry in here and he was familiar in the first three technologies. Then he briefed the 3D Tech (CAD/CAM), Opto-Mechatronics and System Integration from 1992 “established Rapid Prototyping Technology Centre” to 1997 “3D CAD/CAM Popularization Program”.

He

shared the first case which was Bra Cup Machinery Development using 3D

technology to overcome the manufacturing problem. It included double-side laser

scanning system and automatic loader for bra cup molding machine. The total solution for Bra Cup manufacturing process

was showed as following diagram. The

project worked with HKRITA.

Video

of Automatic Loader for Bra Cup Molding Machine (自動化胸杯模壓系統)

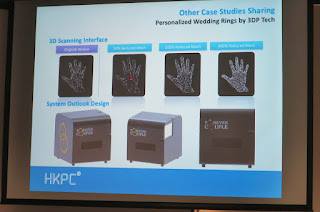

The

second case was the “Personalized Wedding Rings” by 3D Printing Technology. Firstly, Mr. Fung identified the combinations

of sizes for ring finger. Then his team

developed tailor-made scanning system.

The partner company would like to enhance customer experience using 3D

printing to form a prototype

The final machine was showed as follows.

The

last case was the textile defect checking by image recognition that main

employed to inspect the label logo. HKPC

solutions included Tailor-made Scanning System, Knowledge-based System and

Removal System.

After

that Mr. Arnold Wu (Co-founder, The Hong Kong Maker Club) and he introduced

what is the maker and shared how Inno Space to help them from idea to

prototype. He hoped that Inno Space

provided area for different makers to jam new ideas.

Finally,

Ms. Stephanie Huang led us to visit Inno Space facilities.

First

place was 3D scanning.

She

demonstrated the motion capture problem which could help to develop simple

short video.

Then

we visited the 3D Printing centre. She introduced different technologies on 3D

printing such as Laminated Object Manufacturing (LOM), Stereo-lithography (SLA)

and Fused Deposition Modeling (FDM), as well as, Selective Laser Sintering

(SLS).

We walked through the I4.0 centre and went to the workshop of Inno Space.

It

was a maker area with laser cutting, laser welding, casting, machining

workshop, etc.

Stephanie

said the cost for rental such facilities was $800 per month that had 30hr per

week. Moreover, it had 80% discount for

booking 3 months and upto 70% discount for booking 6 months. If you were in partner company, the month

rate down to 50% discount.

Then

we visited the new 3D scanning.

Stephanie

demonstrated how to scan for one of our participants.

The

3D printer was introduced at the end.

Reference:

HKSTP

- http://www.hkstp.org

TecONE

- http://tecone.hkstp.org/t1_web/

Inno

Space - https://innospace.hkpc.org/

The

Hong Kong Maker Club - https://www.facebook.com/HongKongMiniMakerFaire/

20170913:

HKSTP TecONE Seminar “Industry 4.0 and Its Potential Opportunities for Tech

Companies” - https://qualityalchemist.blogspot.hk/2017/09/hkstp-tecone-seminar-industry-40-and.html

沒有留言:

發佈留言