ASQ

Shenzhen LMC organized a seminar on “Minus Quality Assurance (- QA)” (減法品質保證) on 8th Sep 2019

(Sunday) in Shenzhen. The seminar is

full within two hours after the post published.

Dr. Aaron Tong (China Outstanding Quality Professional (中國傑出質量人)) was invited to be the honorary

speaker. Minda and I represented HKSQ to

support Aaron’s talk. Before the

seminar, we were invited by ASQ Shenzhen LMC to have lunch together.

(Left:

Ms. Minda Chiang, Ms. Susanne Chang, I, Mr. Simon Lee (Vice Chair, ASQ Shenzhen

LMC) and Mr. Lorenzo (Operation Chair, ASQ Shenzhen LMC), Dr. Aaron Tong and

Dr. Pat Cheung)

The

venue was closed to the restaurant. Mind and I took a photo for memory.

We met

Mr. Simon Tong (Chair, ASQ Hong Kong LMC) and took a photo for memory.

Dr. Pat

Cheung, Minda and I prepared to learn from Aaron. You could feel how hot in Shenzhen.

In the

beginning, Mr. Simon Lee (Vice Chair, ASQ Shenzhen LMC) introduced the guest

speaker and the only one awarded the China Outstanding Quality Professional (中國傑出質量人) in GBA – Dr. Aaron Tong.

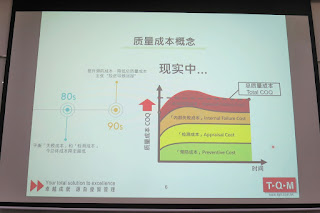

Dr.

Aaron Tong firstly reviewed different quality cost concepts from 80s, 90s and

now.

In 80s, the total Cost of Quality (COQ) defined Failure Cost plus Appraisal Cost that we needed to find the optimal one.

In 90s, the

total COQ included Failure Cost, Appraisal Cost and Preventive Cost. However, it was only an ideal case.

The real

situation was showed as the diagram that it included External Failure Cost,

Internal Failure Cost, Appraisal Cost and Preventive Cost. If we increased Appraisal Cost and Preventive

Cost, firstly Internal Failure Cost would increase immediately and then

External Failure Cost would decrease after some time (say 9 months). External

Failure Cost reduction had latency.

Therefore,

Dr. Aaron Tong proposed minus QA in which did not increase Appraisal Cost and

Preventive Cost, but could reduce Failure Cost significantly. The most important part of –QA from optimal

testing (remove over testing) and decrease the preventive cost so as to reduce

the internal failure cost. Based on Dr.

Aaron Tong past seminars (see reference), his original insight was come from

Deming.

And then

he reviewed the traditional QA (he named addition Quality Assurance (+QA). The following diagram demonstrated the

existing practice in factory.

However,

we needed to find the original source of problem that usually hidden under

water. So that –QA aimed to solve the root cause but not only use addition

resource.

The following table compared both concepts in terms of Cost, Effect, Supply Chain, Stock, After Sale Reliability and Process of Production.

Finally,

Dr. Aaron Tong explained his –QA concept and implementation in two case studies

that one is SUPOR and the other is LED Supplier for IKEA. In SUPOR case, -QA implementation could

reduce the after sale NC percentage from 3% to 0.3% after 50 months. In LED

supplier case, the cycle time was reduced significantly from 14 days to 1 day.

At the end,

Dr. Aaron Tong shared –QA tools to us included:

i)

Effect-Cause Analysis (using Extension thinking)

ii)

HALT / HASS application

iii)

Cross Industry and Cross team during implementation

iv)

Supply Management (No need to do good/best, but need to do right!)

Q&A

Session.

Lastly,

we took a group before left.

After

the seminar, Minda and I visited the new airport in Shenzhen.

Very

large and beautiful.

We saw an

auto machine for medicine.

We had dinner in airport restaurant and then back to HK.

Reference:

ASQ

Shenzhen LMC - https://www.weibo.com/u/3916950978?is_all=1

20170714: ASQ LMC Hong Kong Seminar “From Process

Change to Human Change” - https://qualityalchemist.blogspot.com/2017/07/asq-lmc-hong-kong-seminar-from-process.html

Previous Aaron’s related talk:

20160703:

HKSQ Quality Philosophies Series – Deming Workshop - https://qualityalchemist.blogspot.com/2016/07/hksq-quality-philosophies-series-deming.html

20180414:

HKSQ Congratulate to Dr. Aaron Tong awarded China Outstanding Quality

Professional (中國傑出質量人) 2017 and visit Beijing Industries - https://qualityalchemist.blogspot.com/2018/04/hksq-congratulate-to-dr-aaron-tong.html

20180804:

HKSQ AGM Quality Innovation Seminar on “Extenics and AI Application” - https://qualityalchemist.blogspot.com/2018/08/hksq-agm-quality-innovation-seminar-on.html

2181108:

The 3rd World Summit for Chinese Quality (WSCQ) – Day 1 (Part A) - https://qualityalchemist.blogspot.com/2018/11/the-3rd-world-summit-for-chinese.html

20181117:

HKSQ/Minitab/TQM Seminar on Asset Management and Reliability: Machine Learning

+ AI - https://qualityalchemist.blogspot.com/2018/11/hksqminitabtqm-seminar-on-asset.html

20190829:

The 4th Summit of pre-World Alliance for Chinese Quality (WACQ) – Day 1 (Part

A) - https://qualityalchemist.blogspot.com/2019/08/the-4th-summit-of-pre-world-alliance.html

沒有留言:

發佈留言