Hong Kong QFD Symposium 2016 was

organized by Hong Kong Quality Function Deployment Association (HKQFDA) and co-organized

by Asia Quality Function Deployment Association, Hong Kong Society for Quality

(HKSQ), System Engineering and Engineering Management (SEEM), CityU on 17 Dec

2016. Prof. Yoji Akao had first

suggested QFD in Japan in 1966. So the

symposium aimed to celebrate the important milestone of 50th

Anniversary of QFD and it was also the 2nd time held in Hong

Kong. Before the symposium, Minda and I

took a photo in front of banner – 50 years of QFD.

Mr. Peter Fung (Chairman, HKSQ)

was the master of ceremonies (MC) and he introduced today’s schedule and all

guest speakers.

Then we took a group photo.

In the beginning, Dr. Catherine

Chan (President, HKQFDA) gave a welcome speech.

She said that QFD had been widely applied in various industries and this

year was 50 years of QFD developed which was told by Prof. Yoji Akao when she

studied with him.

The first speaker was Mr. Koji

Tanaka (CEO, Kanjie Associates) who awarded Akao Prize in 2004 and he was director

of Knowledge Management Society of Japan.

He promoted QFD in JUSE. He had

served MTR Cheung Sha Wan Station in 1973.

His presentation today entitled "QFD in Japan & Future

Development of QFD".

Mr. Tanaka said the traditional

QFD expanded the practical use range and evolution of the job function

deployment that created the 3rd generation QFD (e7-QFD). The total

structure included basic knowledge of QFD, “Ba” and the expansion of the

applied domain.

Then Mr. Tanaka briefed the “Ba”

(場) that “The

management is not to manage the member.

It is to make information between people and the stage of mutual

sitmulation of the psychology.” The characteristic

of “Ba” is that “All the members can understand the contents by “Ba” and get

possible to practice tacit knowledge such as the thought of the manager or the

expert know-how”. I found that it was

similar to my paper using Magnetic Field domain approach which presented in ANQ

Congress 2003 in Beijing. So I will

translate “Ba” to “Field” in English.

Mr. Tanaka further explained “Ba”

using Knowledge Conversion Model (Socialization, Externalization, Combination and

Internalization (SECI)) to utilize QFD making “Ba”.

Finally, he explained the

expansion of the applied domain. There

were two types of improvement included business processes and quality of

duties. Improvement of business

processes included the following stages:

-

Clarification of the goal that you should achieve

-

Clarification of the job function

-

Connecting the goal with the job function

-

Setting of a guarantee item and the guarantee level for the

accomplishment

-

Practice development of a design and the management of duties

At the end, Mr. Tanaka stated new

product development aiming at value creation.

He mentioned the Value Creation System to us and concluded “The practice

of the manager produces result of QFD” and “Even with managers, they cannot

change the direction of the wind, but can control the sail freely.”

Dr. Catherine Chan (President,

HKQFDA) presented appreciated certificate to Mr. Koji Tanaka.

The second speaker was Dr. Catherine

Chan (President, HKQFDA; Secretary General, Asia QFD Association & Council

Member of International Council for QFD) and her topic named "QFD from

Japan to Global". She said there

were many new tools and skills added into QFD for the past 50 years. Then she briefed the history of QFD since

1960s in Japan. In that time, Japan

companies faced from B2B to B2C. One of pioneer

companies employed QFD was Toyota.

Then Catherine introduced Prof.

Yoji Akao’s two earliest books in Japan in 1988. In 1990s, Prof. Yoji Akao issued “Introduction

to Quality Deployment” and co-authored with T. Ohfuji & M. Ono for two more

books named “Quality Deployment Methodology Part I (1990) and Part II (1994)”.

After that Catherine briefed the

development of QFD in USA from 1980s to 2000s. For instance, some institutes

and companies employed QFD such as American Supplier Institute (1987), Kaizen

Institute (1987), Ford Motor (1987) and General Motor (1990). Then Prof. Yoji Akao’s books were translated

into English since 1990. QFD Institute

was established in 1994 by Glenn Mazur.

Catherine said House of Quality

named by USA but it named as Quality Table in Japan. At that time, many vehicle industries

employed QFD so the 4-Phase Model (Design Requirement → Part Characteristics → Manufacturing Requirement → Production Operations) was very popular. But

it was one of models in QFD. Voice of

the Customer (VOC) then was focused.

Some people simplified QFD to Blitz QFD using one-page &

all-at-one-glance design to speed up the operation of QFD. Analytic Hierarchy Process (AHP) was also

employed into the scoring that made its ranking more mathematically.

In Asia, the first country

introduced QFD was Korea through Korea Standards Association (1978 – 1995). And then QFD came to Taiwan and the first Chinese

QFD translated book in 1986. QFD

introduced to China by Prof. Akao in 1994.

QFD came to Hong Kong and HKQFDA established in 2009. Catherine said it was similar development

path in China from B2B to B2C and the main concept changed from “Product Out”

to “Market In”. So QFD would become more

important in China.

During the break, we celebrated the

50th anniversary of QFD. We

prepared the birthday cake and sang a song for it.

All guests cut the cake together.

Then we distributed the cake and

enjoy with all participants.

I took some photos with friends

and quality professionals

(Left: Dr. Catherine Chan, Mr.

XXX, Mr. Koji Tanaka, Mr. Jesmer Wong (SSI), Dr. Victor Lo, I, Mr. James Wang

(Philips-China), Dr. Rita Wan (ISSC) and Dr. Jason Kong (ISSC))

(Left: Dr. Rita Wan (Chairlady,

ISSC), Dr. Victor Lo and I)

(Left: Mr. Ricky Cheng (Managing

Director, QP Group), Dr. Janson Kong (ISSC) and I)

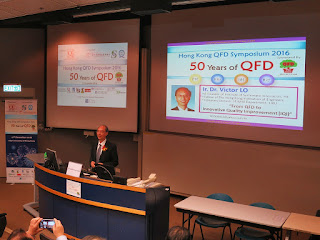

The third speaker was Dr. Victor

Lo (Founder, Institute of Systematic Innovation HK; Honorary Lecturer of IMSE

Dept., HKU) and his presentation named "Form QFD to Innovative Quality

Improvement (IQI)". Firstly, he

briefed QFD was one of the best tools to translate VOC to Product

Specifications.

Dr. Victor Lo then used Kano

Model to express the requirement of customer increased time to time. He quoted

Catherine’s presentation in the 1st QFD symposium (2012) “QFD and

Innovation” that had relationship among them.

Dr. Lo proposed QFD process had Innovation during concept generation and

evaluation as well as detailed design.

After that Dr. Lo said innovation

needed Method and System. He explained “What

is Innovation?” using his own definition that “Novel ways to solve problem that

bring values”. He believed Innovation

equal to Problem Solving.

Dr. Lo introduced Innovative

Quality Improvement (IQI) model which based on Design Thinking, TRIZ, Six Sigma

and CWQC. It involved Innovation tools

& techniques, Project Management and People & Team.

Finally, Dr. Lo demonstrated his

product 50 flash cards based on TRIZ principles and using PKII phases for problem

solving.

Dr. Catherine Chan (President,

HKQFDA) presented appreciated certificate to Dr. Victor Lo.

Prof. Xiong Wei (Director, Centre

for Quality Management, Zhejiang University; VP, Asia QFD Association; Council

Member, International Council for QFD) was the last speaker and his topic

called "QFD in China and Chinese QFD theory". He said “Akao gave his first QFD speech in

China at an event of State Bureau of Quality Technical Supervision in June 1994

(with Ms. Lin MA as interpreter)”. Then Prof Yoji Akao gave lecture on QFD at

Zhangjiajie, Hunan in 1997.

Prof. Xiong Wei said QFD in Japan

was employed very common but it was not in China because of different in

culture. Then Prof. Xiong Wei came back

to China and established QFD research team in 2003 and started to invite

research student since 2006.

Prof. Xiong Wei focused on

Chinese culture such as “Relationship”(講情面), “Almost / Near” (差不多) and “Mild” (中庸), and then using different

methods & models to solve these problems.

After that Prof. Xiong Wei

introduced the “Made in Zhejinang” and its positioning such as Innovation,

Advancement, Responsibility and Collaboration.

The following model explained two

important supports included Innovation and Quality through QFD. So Prof. Xiong Wei concluded that we needed

to make QFD more localization.

Mr. Koji Tanaka presented

appreciated certificate to Prof. Xiong Wei.

After presentation of

appreciation certificates to speakers, we took a group photo.

All guest speakers

All participants

Then I took a photo with Mr. Koji

Tanaka and Prof. Xiong Wei for memory.

After the symposium, we had lunch

together.

We then took a photo in front of

CityU when we left.

Reference:

20120114: Hong Kong QFD Symposium 2012 - https://qualityalchemist.blogspot.hk/2012/01/hong-kong-qfd-symposium-2012.html

Remember Prof. Yoji Akao - Father of Quality Function Deployment

(QFD) - https://qualityalchemist.blogspot.hk/2016/10/remember-prof-yoji-akao-father-of.html

沒有留言:

發佈留言