Electric vehicle (EV) is an exciting topic for transportation based on the technology of power electronics to enable the high efficiency use of the power conversion. The seminar discussed the technology including in-wheel motor, high performance motor drive, high energy density battery, high power charging and condition monitoring and their impacts on the environment, power system network and the human behavior.

Dr. Albert Tsang (past chairman) gave an opening speech of the seminar and introduced the speaker Prof. Eric Cheng who is in-charge Power Electronics Research Centre, Department of Electrical Engineering of Hong Kong Polytechnic University.

Prof. Eric Cheng briefed the content of seminar as follows:

i) The advantage of electric vehicle

ii) MyCar development

iii) Battery and charger

iv) Higher performance vehicle

The advantage of electric vehicle and disadvantage of traditional vehicle were listed below.

· Zero Emission vs Unfavourable Gases Emission

· Power Regeneration vs No Power Regeneration and consume power when stand still

· Low Noise Pollution vs Noise Pollution

· Instant start and direct drive vs Idle speed

· Simple in structure vs structure generate unnecessary heat

· Zero Emission vs Unfavourable Gases Emission

· Power Regeneration vs No Power Regeneration and consume power when stand still

· Low Noise Pollution vs Noise Pollution

· Instant start and direct drive vs Idle speed

· Simple in structure vs structure generate unnecessary heat

Then Prof. Cheng discussed the power electronics and its components design of MyCar.

· Battery Charger – switched mode power converter

· Motor – electromagnetic design

· Motor Drive – inverter design

· Light – LED converter driver

· Safety – EMI study, screening, fault tolerance, system control

· Material / New Devices – Super-capacitor battery modeling, measure of State of Charge (SoC) and State of Health (SoH)

He said the original design of MyCar was using diesel and then they decided to convert into electric drive.

· Battery Charger – switched mode power converter

· Motor – electromagnetic design

· Motor Drive – inverter design

· Light – LED converter driver

· Safety – EMI study, screening, fault tolerance, system control

· Material / New Devices – Super-capacitor battery modeling, measure of State of Charge (SoC) and State of Health (SoH)

He said the original design of MyCar was using diesel and then they decided to convert into electric drive.

Electric Vehicle range per charge was still limited by the battery. So battery technology was one of key focuses in EV development. There were four types of battery used.

i) Lead-acid batteries (relatively inexpensive)

ii) Nickel-metal-hydride battery (High self-discharge & an interim step to lithium-based battery)

iii) Lithium-ion battery (store more energy & larger power density)

iv) Carbon Nano Tube (CNT) battery

Solar Golf Cart involved environmental concern on combining solar energy and electric vehicle.

Battery Management System (BMS) was briefed. It used for cell balance and to avoid charging stops when one cell reaches the peak voltage. Moreover, BMS was able to protect batteries from over temperature, overload and under load, as well as, measuring the correct SoC & SoH.

EV Battery Charger Technology was discussed.

Polymer bonded Magnetics technology was also employed in transformer core.

Two parts were shown.

In-wheel Switched-Reluctance (SR) motor drive was introduced. The motor was built in each wheel in which used differential speed for skid steering.

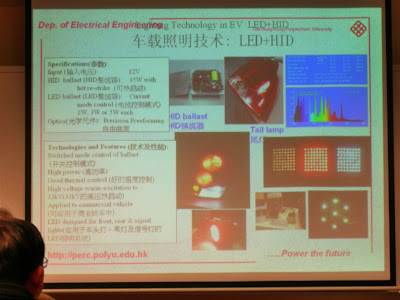

To use LED Lighting technology in Front and Tail Lamp of vehicle was the trend. Thermal design was one of key technology.

Then, Prof. Cheng showed the video about MyCar launch as below.

Prof. Cheng explained the In-wheel motor to us.

Front and Tail LED lighting and integrated sphere for LED testing.

i) Lead-acid batteries (relatively inexpensive)

ii) Nickel-metal-hydride battery (High self-discharge & an interim step to lithium-based battery)

iii) Lithium-ion battery (store more energy & larger power density)

iv) Carbon Nano Tube (CNT) battery

Comparison of different batteries were shown as follows: (Type / Charge & Discharge cycle / Energy)

i) Lead-acid / 400 / 30-40 WHr/kg

ii) Zinc-air / 1000 / 50-60 WHr/kg

iii) NiMH / 800 / 70-80 WHr/kg

iv) Li-ion / 1000 / 100-160 WHr/kg

v) CNT / 2000 / 180-240 WHr/kg

vi) Hydrogen Fuel cell / 1000 / 150-200 WHr/kg

The CNT battery was a 99% recyclable, rechargeable battery that utilizes a highly-conductive carbon nano tube coating to modify the fabrication of batteries.

i) Lead-acid / 400 / 30-40 WHr/kg

ii) Zinc-air / 1000 / 50-60 WHr/kg

iii) NiMH / 800 / 70-80 WHr/kg

iv) Li-ion / 1000 / 100-160 WHr/kg

v) CNT / 2000 / 180-240 WHr/kg

vi) Hydrogen Fuel cell / 1000 / 150-200 WHr/kg

The CNT battery was a 99% recyclable, rechargeable battery that utilizes a highly-conductive carbon nano tube coating to modify the fabrication of batteries.

The photo showed the CNT battery. (So thin)

Solar Golf Cart involved environmental concern on combining solar energy and electric vehicle.

Battery Management System (BMS) was briefed. It used for cell balance and to avoid charging stops when one cell reaches the peak voltage. Moreover, BMS was able to protect batteries from over temperature, overload and under load, as well as, measuring the correct SoC & SoH.

EV Battery Charger Technology was discussed.

Polymer bonded Magnetics technology was also employed in transformer core.

Two parts were shown.

In-wheel Switched-Reluctance (SR) motor drive was introduced. The motor was built in each wheel in which used differential speed for skid steering.

To use LED Lighting technology in Front and Tail Lamp of vehicle was the trend. Thermal design was one of key technology.

Then, Prof. Cheng showed the video about MyCar launch as below.

Finally, he concluded the following No.1s:

i) 1st plastic magnetic core for power conversion in the world;

ii) 1st Large EV research group in Hong Kong;

iii) 1st Self developed commercial electric vehicle in Hong Kong;

iv) 1st In-wheel motor using the switched-reluctance technology;

v) 1st Integrated charger and motor drive in Town car.

i) 1st plastic magnetic core for power conversion in the world;

ii) 1st Large EV research group in Hong Kong;

iii) 1st Self developed commercial electric vehicle in Hong Kong;

iv) 1st In-wheel motor using the switched-reluctance technology;

v) 1st Integrated charger and motor drive in Town car.

After the seminar, we visited Power Electronics Research Cent

Prof. Cheng explained the In-wheel motor to us.

Front and Tail LED lighting and integrated sphere for LED testing.

沒有留言:

發佈留言