The Hong Kong Society for Quality (HKSQ) organized

a webinar named “Why we need Inspection Service” on 24th Jun 2022. Inspection

is the most common method of attaining standardization, uniformity, and quality

of workmanship on the product. The webinar aims to introduce inspection service

based on acceptance quality level (AQL), different types of inspection and

competence based on ISO 17020. The guest speaker was Dr. Jane WK Wong (Vice-chairman,

HKSQ; Retail Sales Director, General Inspection Services Co., Ltd.) and she has

over 30 years’ experience in inspection business.

Firstly, Dr. Jane Wong briefed some reasons to

employ inspection service such as reducing the risk, ensuring the contractual

obligations, identifying the problem before shipment, etc. Then she mentioned

the QA and QC in the global supply chain with certification, testing and

inspection service.

Then she stated different types of inspection

including “Pre-production Inspection (First Article Check)”, “During Production

Inspection (DPI) / In-line Inspection” and “Pre-Shipment Inspection (PSI) /

Final Random Inspection (FRI)” under different product categories.

After that Dr. Wong used a case to example

inspection plan such as item A with 1200 pieces and 80 samples inspected. Number

of cartons is 60 and number of drawn is square root of 60 ~ 8.

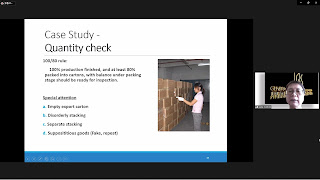

Finally, she employed case study on single

sampling plans for normal inspection to explain the AQL inspection table. Usually, customer would select general

inspection level II where level I is smaller sample size and level III is larger

sample size. She further explained that reject

if any critical defect is found because it related to safety. Major defect is

some broken part of product and cannot sale.

Minor defect is some flaw but still can sale.

Lastly, she introduced the roadmap of inspection.

Before

end of webinar, we had discussed many items during Q&A sessions as below.

-

Defects Per Million Opportunities (DPMO) employed

in factory;

-

Proof of Concept (PoC) product is only one

or two piece(s) that inspection body would communicate with customer to arrange

pre-production inspection, etc.

We took a group photo

for memory at the end.

沒有留言:

發佈留言