The HKSQ

seminar named “Future Manufacturing – Industry 4.0, Made in China 2025 and

Internet+” co-organized by Hong Kong Society for Quality (HKSQ) and SEEM Dept.,

CityU on 27th Aug 2016. Industry

4.0, Made in China 2025 and Internet+ are the trend of future

manufacturing. Dr. YC Chau was invited

to share his view on those elements and update after HKIE seminar on Industry

4.0 held one year ago. Before the

seminar, I (HKSQ) took a photo with my old friend Ir. Dr. YC Chau and Dr. CF

Luk.

Dr. KS

Chin represented SEEM Dept., CityU to give welcome speech. Dr. Chin encouraged industrial professionals

could study for research degree like Dr. YC Chau.

Then Mr. Peter Fung (Chairman, HKSQ) gave an opening speech and introduced HKSQ to all participants. This year is also our society 30th Anniversary.

After

that I introduced Dr. YC Chau to all and briefed his background. Dr. YC Chau graduated from PolyU and received

MBA from University of South Australia, as well as, PhD from SEEM Dept.,

CityU. Dr. Chau had been working in TDK

(Tokyo Denki Kagaku) Corporation since 198, where he was currently the Vice

President of China Operation Improvement Group.

He was also an Adjunct Professor and Industrial Adviser with CityU. Moreover, he was member of HKIE, Senior

member of IIE and member of IET.

In the

beginning, Ir. Dr. YC Chau (Vice President, China Operation Improvement Group,

TDK) introduced the background of Industry 4.0. He had written an article entitled “Industry

4.0 with Implications for Made-in-China 2025” in HKIE magazine named “Engineer”

Vol 44, May 2016. He also briefed the

history from the 1st to 4th Industrial Revolution. He said Industry 4.0 was not equal to the 4th

Industrial Revolution but they happened at the same time. Industry 4.0 was only Germany Manufacturing

Strategy.

Then Dr.

Chau briefed USA stated White House SMART Manufacturing, Japan mentioned

Factories Connected Together, China has talking about Made in China 2025, and

Germany promoted German Manufacturing DNA. He mentioned China economic had

achieved over England and reaching USA (超英趕美). Dr. Chow agreed with SIEMENS

Vision of Industry 4.0 that “A vision of tomorrow’s manufacturing: Products

finding their way independently through the production process. In intelligent factories, machines and

products communicate with each other, cooperatively driving production.”

Dr. Chau

introduced three Key Technology of Industry 4.0 and they were Big Data,

Internet of Things (IoT) and Cybert Physical Systems (CPS). He said we collected big data within workshop

which could be changed from Preventive Maintenance to Predictive

Maintenance. Then he showed video of Pizza

example (In Chinese) in which demonstrated how accuracy sale in future.

IoT connected

among Supplier, Manufactor, Distributor and Customer; and formed IoT supply

chain migration with cost opportunities.

He used Video of Intel’s Vision of IoT to demonstrate IoT concept.

He then

stated Cyber Physical System (CPS) in which 3C model of CPS was mentioned where

3C for Computation, Communication and Control. Dr. Chow said employing CPS was

very expensive and one example was MTR Operations Control Centre.

He told

us MTR should be no need to have driver actually but citizen had not ready to

accept it. Another application was Off Line Equipment Diagnostic such as CPS

Opportunities in Jet Turbine. He said

airplane could be hijacked through internet theoretically; therefore, airplane

companies hadn’t shared all information online.

Another example was Baidu Smart Chopsticks. Many applications were related sensor. So the sensors would become smaller, cheaper, more versatile and it could measure more data and interact with each other.

Dr. Chau

said from the integration of Big Data, IoT and CPS, we got from Industrial 4.0

was “4S” where 4S stands for Smart Factory, Smart Products, Smart Process and

Smart Services. Dr. Chow concluded that

Industrial 4.0 goal was seamless manufacturing through a merging of industry

and IT, machines and systems would gain the flexibility to adapt to today’s

rapidly changing processes.

In

addition, he said Real Time Overall Equipment Effectiveness (OEE) System would

be achieved using the Framework included Vertical and Horizontal Integration

Manufacturing Execution System plus ERP system.

After that he introduced the further business opportunities through “System

of Systems” (SoS). Dr. Chau asked us two

things should be considered in Industry 4.0 that was Human Position and Quality

Role.

The 2nd

part introduced Internet+ and Made in China 2025. Dr. Chau quoted China’s Premier Li Keqiang

announcement about Made in China 2025 in earlier March 2015 in Beijing. The program was created to drive smart

technology in China’s manufacturing plants.

He said China was pursuing an “Internet Plus” action plan that seek to

drive economic growth by integration of Internet Technology with Manufacturing

and Business. Then Dr. Chau explained

the reason of Internet+ using Asia Pacific Internet Speed data that China was

very low speed in 2015. Singapore and

Hong Kong were number 1 and 2.

Therefore, Hong Kong had our own advantage using internet.

Based on

Premier Li’s report, “Internet Plus” entailed integration of Mobile Internet, Cloud

Computing, Big Data and Internet of Things (IoT); which included modern

manufacturing, fostering new industries and business development (e.g. e-Commerce,

Industrial Internet and Internet Finance).

That transformed from “+ Internet” to “Internet +”. The following diagram demonstrated what

Internet + different industries which created different products / services.

After

that Dr. Chau introduced “Made in China 2025” that was the first 10-year action

plan designed to transform China from a manufacturing giant into world

manufacturing power. The three step

strategy was shown as follows:

2015-2025:

From Manufacturing Giant (工業大國) to World Manufacturing Power (工業强國)

2025-2035:

Form Elementary Level to Medium Level

2035-2049:

Leading Manufacturing Power which marks (the 100th anniversary of

the founding of PRC)

“Made in

China 2025” had 5 key engineering areas, included “Innovation Center”, “Smart

Manufacturing”, “Self-sufficiency in Infrastructure”, “Green Demonstration

Projects” and “Indigenous R&D”.

Dr. Chau

said Hong Kong had many SMEs but they hadn’t capability to implement Industry

4.0 but one thing his suggested to following the China strategies and used our

advantages to find opportunities. The 10

sectors of “Made in China 2025” were “New Information Technology”, “Numerical

Control Tools”, “Aerospace Equipment”, “High-tech Ships”, “Railway Equipment”, “Energy

Saving”, “New Materials”, “Medical Devices”, “Agricultural Machinery” and “Power

Equipment”.

Moreover,

Dr. Chau also mentioned the Nine Tasks as follows:

-

Improving Manufacturing Innovation

-

Integrating Technology and Industry

-

Strengthening the Industrial Base

-

Fostering Chinese Brands

-

Enforcing Green Manufacturing

-

Promoting Breakthroughs in 10 Key Sectors

-

Advancing Restructuring of Manufacturing Sector

-

Promoting Service Oriented Manufacturing and Manufacturing-related

Service Industries

-

Promoting International Manufacturing

And then

Dr. Chau compared Germany Industry 4.0 and Made in China 2025 that they were

same as National Strategy. The

difference was showed as follows:

For

Industry 4.0, it focused on the development of fully-automated “Smart Factories”

that made products fully customization.

For Made

in China 2025, it span the whole manufacturing industry to apply advanced idea

not only form Germany but also from the US and Britain among others.

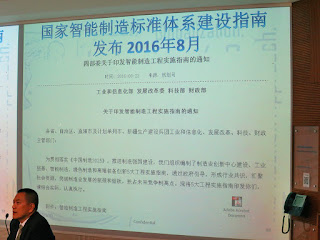

Dr. Chau

told us China government had draft the National Smart Manufacturing Standard

consultation paper in October 2015 and the guideline (國家智能製造標準體系建設指南) was published in August

2016.

Then Dr.

Chau showed the video about the bearing made in Germany and China that

indicated the level difference. We need

to catchup the gap as soon as possible.

Finally,

Dr. Chau said the road to be Manufacturing Power was difficult. When others walk, we need to run. Others run, we need to fly!

In

Q&A Session, many questions were discussed.

Mr. Edmond

Cheung asked how SMEs started Industry 4.0 because of resource limitation. Dr. Chau said it depended on their need. The start part could be some existing

manufacturing equipment data such as micro real time OEE.

Dr.

Aaron Tong said the short product life cycle and system changed so fast that could

be difficult to adopt such standardization.

Dr. Chau agreed that we needed more flexibility and customization. He quoted Nike sport shoes as example that

they could employ 3-D printing technology and tail-made a sport shoes for each

customer.

Mr.

Peter Fung asked how Hong Kong achieved reindustrialization. Dr. Chau said most SMEs in Hong Kong seek for

surviving and he advised SMEs based on their own capability to adopt different position

under China policy.

Finally,

I gave close remark and added a comment that quality consultant could provide a

service for evaluating manufacturing plant to achieve which industry level and

could adopt what kind of Industry 4.0 technology.

Reference:

HKSQ – www.hksq.org

What is

Big Data? Pizza example (In Chinese) - https://www.youtube.com/watch?v=bSANNsqfy6E

Intel’s

Vision “Transform Manufacturing with the Internet of Things” - https://www.youtube.com/watch?v=5OQQZ9eWF-4

Hong

Kong MTR Operations Control Centre (TVB Program) - https://www.youtube.com/watch?v=lUpJFy-pOmg

Industry

4.0: Integrated Industry reaches the next level - www.youtube.com/watch?v=ccB6e18VwsQ

Differences

between made in China & made in Germany - https://www.youtube.com/watch?v=RepARd6db7c

Recommendations

for implementing the strategic initiative INDUSTRIE 4.0 (2013) - http://www.acatech.de/fileadmin/user_upload/Baumstruktur_nach_Website/Acatech/root/de/Material_fuer_Sonderseiten/Industrie_4.0/Final_report__Industrie_4.0_accessible.pdf

20150820:

HKIE Seminar on Industry 4.0: The 4th Industrial Revolution - https://qualityalchemist.blogspot.hk/2015/08/hkie-seminar-on-industry-40-4th.html

沒有留言:

發佈留言