After that Mr. Allen Ma (CEO, HKSTP) came back to the real world and gave welcome speech. He said IoT contained “Integration” and “Realization” and he mentioned the “Power of Collaboration” through HKSTP three platform named “Robotic Engineering”, “Smart City” and “Health Ageing”.

The Honourable Nicholas W Yang, JP (Secretary for Innovation and Technology, HKSAR) was our Guest-of-Honour and gave an opening speech. He said government supported Innovation and Technology industry and Re-industrialization was very important in Hong Kong. Moreover, IoT could provide quality improvement opportunity for young people. Lastly, He reminded us that International IT Fest would be held from 11-23 April 2016.

Group photo was taken.

The first keynote speaker was Mr. Chris Ip (Senior Partner, McKinsey & Company) and his topic entitled “Internet of Things – Beyond the Hype, Mapping the Value and a Case for Action”. Firstly, Mr. Ip explained McKinsey prediction that IoT was poised to be the biggest technological revolution.

Then he explained four myths and truths in the following diagram. Then he briefed Industry 4.0 which enabled by IoT. Industry 4.0 was the application of the Internet of Things (IoT) in traditional industries: sensors in everything, networks everywhere and analyze everything.

Mr. Chris Ip also introduced the Industry 4.0 model which included “Disruptive Technology” and “Transform into a digital company (with Operational Effectiveness and Business Model)”.

I would like to remark two points from Mr. Chris Ip presentation below.

i) Disruptive Technologies’ three elements included Connectivity, Affordability and Interoperability.

ii) Four main trends regarding New Business Models included “As-a-service business model”, “Platforms”, “IPR-based business models” and “Data-driven business models”.

Finally, Mr. Ip concluded that digital company needed to establish sound digital foundations in 5 dimensions included “Build Digital Capability”, “Enable Collaboration in the Ecosystem”, “Manage Data as a Valuable Asset”, “Implement 2-speed System/Data Architecture” and “Manage Cyber-Security”.

The second keynote speaker was Mr. Gardner Carrick (Vice President, The Manufacturing Institute, US National Association of Manufacturers) and he presented a topic named “A Report on U.S. Manufacturing”. In the beginning, Mr. Carrick briefed ISM Manufacturing Purchasing Managers’ Index from Jan 2015 to Feb 2016 and the trend was decreasing. Then he asked a question “A Resurgence in U.S. Manufacturing?” He found that the output of U.S. Manufacturing was increasing from 2010 to 2014 but Manufacturing Jobs were decreased from 2002 to 2009 and then flatten.

After that he said there were four factors driving resurgence that were “Cost of Business Overseas”, “Transportation Costs”, “U.S. Energy Prices” and “U.S. Innovations”. And that he highlighted 3 of gallery of disruptive technologies (i.e. Internet of Things, Advnced Robotics and 3D Printing).

Finally, he mentioned some perception solutions for manufacturing. He added 3 out of 10 parents would encourage their kids to pursue manufacturing as a career but kids’ own interests / experiences had 64% career influence based on the survey. Then Mr. Carrick raised Quality Education as a solution such as inviting the Public for MFG DAY, “Dream It. Do It.” (DIDI) Ambassador Program, etc. There were 15 Endorsed certifications from different associations and company included ASQ!

During the tea break, I met many friends and took some photos for memory.

(Left: Prof. Gregg Li (CEO, Gregg Li and Co; Vice Chairman of Business and Professionals Federation of Hong Kong)), Dr. Raymond Leung (Vice Chairman, Hong Kong Industry-University-Research Collaboration Association (HKIUR)) and I)

(Left: Mr. Simon Tong (HKSQ), Dr. Michael Li (ISIHK) and I)

(Left: Prof. Fugee Tsung (HKUST & HKSQ) and I)

The third keynote speaker was Mr. Li Beiguang (Ministry of Industry and Information Technology of the People’s Republic of China) and his presentation was “China Manufacturing 2025”. He would focus on four key questions on China Manufacturing: “What it thinking like?” “How to observe?” “How to do?” and “How to promote?”

Then Mr. Li explained there were 5 policy named “Innovation Driven”, “Quality First”, “Green Development”, “Structure Optimization” and “Talent Based”.

Mr. Li said many countries launched their own manufacturing plan included USA, UK, EU, Germany, France, Japan, Korea and India. He also explained Industry in different levels as follows:

After that Mr. Li stated the way of China Manufacturing under 811 strategies. The domains were “Innovation”, “Quality”, “Green”, “Structure” and “Talent”.

Mr. Jean-David Miquel (France Exper Committee Member, ISO/IEC JTC1/WG10) was the fourth keynote speaker and his topic named “Industry 4.0 – Smart Manufacturing”. He quoted the IoT means “An infrastructure of interconnected objects, people, systems and information resources together with intelligent services to allow them to process information of the physical and the virtual world and react.”

Then he introduced SG5 & WG10 for Standards & Reference Architectures identification (www.jtc1.org ) as well as IoT interoperability context. WG10 works on Reference Architecture (RA) included System RA (SRA), Communications RA (CRA) and Information RA (IRA).

Mr. Miquel also mentioned Smart Manufacturing Standards and its consideration.

Mr. Jing Bing Zhang (Research Director Robotics Manufacturing Insights, IDC Asia/Pacific) was fifth speaker and his topic named “Third Platform Technologies: Enabling Digital Transformation of Manufacturing”. In the beginning, Mr. Jing explained IoT was the 3rd Platform Innovation Accelerators. Innovation Accelerators were opened up new revenue streams, created information-based organization and changed the way of work so as to drive Digital Transformation of all business aspects.

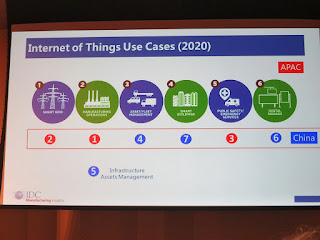

And then Mr. Jing analyzed IoT use cases in APAC and China. The priority was found different that China was more focused on Public Safety/Emergency Services. He also stated IoT for Smart Manufacturing and Logistics based on enhancing Efficiency (Smart Manufacturing), Agility (Connected Supply Chain) and Value (Connected Products).

Before the lunch break, Mr. Albert Wong (CCDO, HKSTP) introduced the Smart Living @ Science Park.

Since I needed to introduce ISO 9001 QMS in SP for IVE students this afternoon, I was missing 3 keynotes speakers’ presentation.

Mr. Ralf Schonherr (BMW Group) was ninth keynote speaker and his presentation entitled “BMW Project Industry 4.0: Digitization and Innovative Robotic Systems for Production”. He said digitalization supported their production system both continuous improvement and disruptive process change.

Mr. Schonherr mentioned that digitalization could leverage its potential for Time, Quality and Cost (Money) (i.e. TQM!).

The last speaker in the morning session was Mr. Kay Matzner (International Project Manager, bei Fraunhofer-Gesellschaft) and his presentation was “German-Chinese and Hong Kong Cooperation Paths on Industry 4.0”. His talk included Evolution status in Germany, and cooperation in both Hong Kong and China.

Then Mr. Matzner briefed the challenges of German industry 4.0 included unclear benefits, insufficient labor, missing standards, etc. After that he discussed some German-Chinese cooperation issues. Germany had the advanced technology needed for Chinese Industry 4.0 but they were worried to strengthen Chinese competitors. Moreover, Chinese data control laws making effective cooperation’s unthinkable. Therefore, the German government would not proactive support German-Chinese research collaboration on Industry 4.0.

On the other hand, Fraunhofer provided training on Industry 4.0 in HKSTP in Feb 2016 in order to improve the innovation culture of Industry 4.0 in Hong Kong. Hong Kong could be developed as China Knowledge Base for Industry 4.0 technologies.

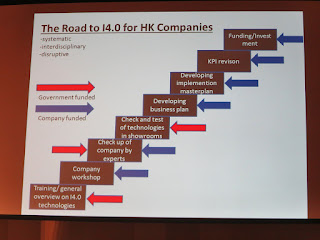

Lastly, Mr. Matzner mentioned the roadmap for Hong Kong companies toward Industry 4.0.

ii) Four main trends regarding New Business Models included “As-a-service business model”, “Platforms”, “IPR-based business models” and “Data-driven business models”.

Finally, Mr. Ip concluded that digital company needed to establish sound digital foundations in 5 dimensions included “Build Digital Capability”, “Enable Collaboration in the Ecosystem”, “Manage Data as a Valuable Asset”, “Implement 2-speed System/Data Architecture” and “Manage Cyber-Security”.

After that he said there were four factors driving resurgence that were “Cost of Business Overseas”, “Transportation Costs”, “U.S. Energy Prices” and “U.S. Innovations”. And that he highlighted 3 of gallery of disruptive technologies (i.e. Internet of Things, Advnced Robotics and 3D Printing).

Finally, he mentioned some perception solutions for manufacturing. He added 3 out of 10 parents would encourage their kids to pursue manufacturing as a career but kids’ own interests / experiences had 64% career influence based on the survey. Then Mr. Carrick raised Quality Education as a solution such as inviting the Public for MFG DAY, “Dream It. Do It.” (DIDI) Ambassador Program, etc. There were 15 Endorsed certifications from different associations and company included ASQ!

During the tea break, I met many friends and took some photos for memory.

(Left: Prof. Gregg Li (CEO, Gregg Li and Co; Vice Chairman of Business and Professionals Federation of Hong Kong)), Dr. Raymond Leung (Vice Chairman, Hong Kong Industry-University-Research Collaboration Association (HKIUR)) and I)

(Left: Mr. Simon Tong (HKSQ), Dr. Michael Li (ISIHK) and I)

(Left: Prof. Fugee Tsung (HKUST & HKSQ) and I)

The third keynote speaker was Mr. Li Beiguang (Ministry of Industry and Information Technology of the People’s Republic of China) and his presentation was “China Manufacturing 2025”. He would focus on four key questions on China Manufacturing: “What it thinking like?” “How to observe?” “How to do?” and “How to promote?”

Then Mr. Li explained there were 5 policy named “Innovation Driven”, “Quality First”, “Green Development”, “Structure Optimization” and “Talent Based”.

Mr. Li said many countries launched their own manufacturing plan included USA, UK, EU, Germany, France, Japan, Korea and India. He also explained Industry in different levels as follows:

-

Industry 1.0: Handmade product with small production (Return)

-

Industry 2.0: Mass Production (Leave)

-

Industry 3.0: Small Amount Production (Breakthrough)

-

Industry 4.0: Batch Production with highly customization (Expectation)

After that Mr. Li stated the way of China Manufacturing under 811 strategies. The domains were “Innovation”, “Quality”, “Green”, “Structure” and “Talent”.

Lastly, Mr. Li mentioned the weakness part (say Death Valley) was the commercialization from universities/gov to industry.

Mr. Jean-David Miquel (France Exper Committee Member, ISO/IEC JTC1/WG10) was the fourth keynote speaker and his topic named “Industry 4.0 – Smart Manufacturing”. He quoted the IoT means “An infrastructure of interconnected objects, people, systems and information resources together with intelligent services to allow them to process information of the physical and the virtual world and react.”

Then he introduced SG5 & WG10 for Standards & Reference Architectures identification (www.jtc1.org ) as well as IoT interoperability context. WG10 works on Reference Architecture (RA) included System RA (SRA), Communications RA (CRA) and Information RA (IRA).

Mr. Miquel also mentioned Smart Manufacturing Standards and its consideration.

Mr. Jing Bing Zhang (Research Director Robotics Manufacturing Insights, IDC Asia/Pacific) was fifth speaker and his topic named “Third Platform Technologies: Enabling Digital Transformation of Manufacturing”. In the beginning, Mr. Jing explained IoT was the 3rd Platform Innovation Accelerators. Innovation Accelerators were opened up new revenue streams, created information-based organization and changed the way of work so as to drive Digital Transformation of all business aspects.

And then Mr. Jing analyzed IoT use cases in APAC and China. The priority was found different that China was more focused on Public Safety/Emergency Services. He also stated IoT for Smart Manufacturing and Logistics based on enhancing Efficiency (Smart Manufacturing), Agility (Connected Supply Chain) and Value (Connected Products).

At the end, Mr. Jing concluded the future factory was Smart Manufacturing and considered “Cognitive”, “Mobility”, “Analytics”, “Safe & Secure”, Connected” and “3D Printing”.

Before the lunch break, Mr. Albert Wong (CCDO, HKSTP) introduced the Smart Living @ Science Park.

Since I needed to introduce ISO 9001 QMS in SP for IVE students this afternoon, I was missing 3 keynotes speakers’ presentation.

Mr. Schonherr mentioned that digitalization could leverage its potential for Time, Quality and Cost (Money) (i.e. TQM!).

Finally, he introduced Innovative Robotic System which used “Sensitive” lightweight robot technology, redefining the “Role of Space” between Human Being and Maching, Flexible automation according to relocation and usage, as well as, Smarter System. Lastly, Mr. Schonherr concluded that “The Future is not ours to see – But it is

ours to create it.”

The last speaker in the morning session was Mr. Kay Matzner (International Project Manager, bei Fraunhofer-Gesellschaft) and his presentation was “German-Chinese and Hong Kong Cooperation Paths on Industry 4.0”. His talk included Evolution status in Germany, and cooperation in both Hong Kong and China.

Then Mr. Matzner briefed the challenges of German industry 4.0 included unclear benefits, insufficient labor, missing standards, etc. After that he discussed some German-Chinese cooperation issues. Germany had the advanced technology needed for Chinese Industry 4.0 but they were worried to strengthen Chinese competitors. Moreover, Chinese data control laws making effective cooperation’s unthinkable. Therefore, the German government would not proactive support German-Chinese research collaboration on Industry 4.0.

On the other hand, Fraunhofer provided training on Industry 4.0 in HKSTP in Feb 2016 in order to improve the innovation culture of Industry 4.0 in Hong Kong. Hong Kong could be developed as China Knowledge Base for Industry 4.0 technologies.

Lastly, Mr. Matzner mentioned the roadmap for Hong Kong companies toward Industry 4.0.

Reference:

HKSTP - http://www.hkstp.org

APAC Innovation Summit - http://www.apacinnosummit.net/aboutus

20141203: HKSTP APAC Innovation

Summit 2014 - http://qualityalchemist.blogspot.hk/2014/12/hkstp-apac-innovation-summit-2014.html

20150416: IoT Symposium 2015 - http://qualityalchemist.blogspot.hk/2015/04/iot-symposium-2015.html

20150642: HKSTP APAC Innovation

Summit 2015 - Robotic - http://qualityalchemist.blogspot.hk/2015/06/hkstp-apac-innovation-summit-2015.html

沒有留言:

發佈留言