In the beginning, Dr. Sammy Wan (President, IIE (HK)) gave an opening speech. He said industry engineer methodology was able to apply in different field included transportation, parks, public utility, logistic and healthcare, etc. It was honor that the seminar had invited different IE professional to share their experience.

It was our honored to have Ir. Dr. the Hon Lo Wai-kwok, BBS, JP (Member of the Legislative Council (Engineering Functional Constituency) to deliver an honorable speech. Dr. Lo said his first job was in IE and his first Master degree was also in IE. He remembered the principles in IE such as 4M – Man, Machine, Money and Method. Moreover, the first IE Internation Conference in China was held in 1988 which organized by HKIE – PIE division (now named MIE division).

Then Dr. Wan presented souvenir to all guest speakers.

I was honor to take a photo with Dr. Lo before he went back to Legislative Council of Hong Kong (Legco) for meeting.

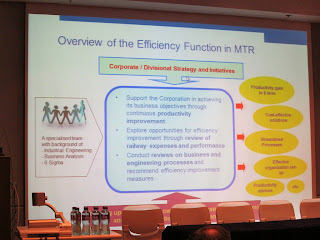

The first speaker was Mr. Ryan Y.Y. Li (Acting Corporate Efficiency Manager, MTR Corporation) and his topic entitled “Application of IE Techniques in Railway Service Delivery”. Mr. Li introduced the challenge in MTR for daily patronage over 5 million. Highly cost effective, no compromise in safety and quality were key challenge in MTR.

Mr. Li explained how Specialised Team in Corporate Efficiency Unit used IE knowledge could help in MTR to integrate various areas of railway operational and asset management knowledge and expertise. For example:

- To identify effectiveness and productivity improvement opportunities;

- To provide recommendations for achieving higher cost effectiveness and raising productivity;

- To facilitate implementation of improvement actions.

Mr. Li said the team approach was important through identified initiatives, conducted review, defined improvement actions and implemented changes. They were advocates of mind-set change for challenging the shortfalls in productivity during participation in the team environment.

Finally, Mr. Li introduced different typical application of IE techniques in MTR including:

- Enhancement of workshop capacity for new train overhaul

- M-Train overhaul process study

- Maintenance strategy for Light Rail Track Point machine assembly maintenance

- Maximizing utilization of non-traffic-hours (NTH)

- Customer service centre work study

- Review on business processes for ticket inspection unit

- Standardization of allowance claim process

Mr. Li shared his personal remarks that IE application was not necessarily rocket-science technology but it closed to our daily life. IE focused on taking a holistic view, and working with experts in different specialized areas, as well as, managing the white space of the organization chart. Moreover, he said while the theoretical base of IE was a science but its application was an art. Nevertheless, the most important complementary element for successful application of IE methodology was “Common Sense”!

The second speaker was Ms. Rosalyn Woo (Industrial Engineering Manager, Hong Kong Disneyland) and her presentation named “Turning Science into Magic in a Theme Park”. She briefed the four keys of Disney Guest Service included Safety, Courtesy, Show and Efficiency.

She said that the IE competencies included Capacity/Demand Analysis, Measuring the Impact, Process Design & Improvement, and Advanced Analytics. Its application covered Project Development (e.g. Park Expansion), Cost & Labor Optimization, and Operational Planning & Support. For costuming Inventory, the following activities were employed to reduce the labour cost, laundry cost, transaction time and inventory.

Finally, Mr. Li introduced different typical application of IE techniques in MTR including:

- Enhancement of workshop capacity for new train overhaul

- M-Train overhaul process study

- Maintenance strategy for Light Rail Track Point machine assembly maintenance

- Maximizing utilization of non-traffic-hours (NTH)

- Customer service centre work study

- Review on business processes for ticket inspection unit

- Standardization of allowance claim process

Mr. Li shared his personal remarks that IE application was not necessarily rocket-science technology but it closed to our daily life. IE focused on taking a holistic view, and working with experts in different specialized areas, as well as, managing the white space of the organization chart. Moreover, he said while the theoretical base of IE was a science but its application was an art. Nevertheless, the most important complementary element for successful application of IE methodology was “Common Sense”!

The second speaker was Ms. Rosalyn Woo (Industrial Engineering Manager, Hong Kong Disneyland) and her presentation named “Turning Science into Magic in a Theme Park”. She briefed the four keys of Disney Guest Service included Safety, Courtesy, Show and Efficiency.

She said that the IE competencies included Capacity/Demand Analysis, Measuring the Impact, Process Design & Improvement, and Advanced Analytics. Its application covered Project Development (e.g. Park Expansion), Cost & Labor Optimization, and Operational Planning & Support. For costuming Inventory, the following activities were employed to reduce the labour cost, laundry cost, transaction time and inventory.

IE activities included:

- Project ROI, Technology testing and evaluation, RFID tags change-out schedule, Facilities and user interface design, Process flow design and Report creation

The Third speaker was Ir. Peter Chak (Customer Enquiries and Installation Services Manager, The Hong Kong and China Gas Company) and his presentation was “Inspection Robot for Gas Service Pipes”. Mr. Chak briefed the background of transmission of town gas. Then he explained why the risers got corroded because of building environment (e.g. Drainage pipes, Acid wash of external walls) and Hong Kong climate (High temp, Near saturation humidity, Sea-salt corrosion and Air pollutants).

Then Mr. Chak introduced the regular safety inspection for more than 1.75 million accounts and the cycle time was 18 months. But the low access rate during regular safety inspection (below 50%) and more than 50% risers were not able be inspected. Therefore, they developed Riser Inspection Robot with gas detector and camera which collected the image and leakage signals, then transferred by wireless system. The robot contained three system included Lifting system, Motion system and Inspection system. There were six classes of riser corrosion through vision inspection of the image taken. Moreover, Town Gas developed a Riser Health Index to monitor the healthiness of risers. Finally, Mr. Chak concluded they would development a comprehensive pipeline inspection system continuously.

Mr. Lam Wing-chiu (Terminal & Capacity Planning Manager, Modern Terminals Limited) was the fourth speaker and his topic entitled “Productivity Uplifting in Container Terminal”. Mr. Lam introduced the business of container terminal that they moved container boxes "to" and "from" container vessels to inland transportation. He said the container crane in horizontal level, indicating under operation. If the container crane left up, it mean the crane idle.

Reviewing the port statistics of top 10 container port in the world, Hong Kong was ranked second (after Singapore) since 2006 and then Hong Kong became the third port (after Singapore and Shanghai) since 2007. Shanghai overtook Singapore as the world's busiest container port in 2010. In 2012, The million TEU* of Shanghai, Singapore, Hong Kong and Shenzhen were 32.5, 31.6, 23.1 and 22.9, respectively.

(*The unit of container throughput is million TEU (Twenty-foot Equivalent Unit).)

The following diagram was comparison the throughput among Hong Kong, Shenzhen and Nansha. It could be confirmed Shenzhen would takeover Hong Kong in 2003 because of Dock Strike.

After that Mr. Lam introduced the "New Horizon" project in MIT aiming to improve operation performance and enhance productivity through changes three areas include Process Review, Technology Upgrade and Organization Realignment. The process would focus on Work flow review, Interviews, Time & Motion study and Activity log.

Mr. Harry Li (MD, Oriental Enterprise Management Solutions Ltd.) was the fifth speaker and his presentation was “Simulation Models for the Service Industry”. Mr. Li mentioned Simulation for Business allowed organization to "Experiment" using an accurate model before "flying the real thing" and allowed Businesses to Innovate profitably by enabling Low Cost "Serious Play".

Then Harry introduced several major applications of systems simulation in service industry such as Transportation, Airport, Call Centre, Financial, Insurance, Healthcare, and Logistics, etc. After that Harry shared his projects in Transportation System and Healthcare System.

For transportation system, the project objective was to simulate the flow of passengers in metro stations to identify bottlenecks and points of congestion during rush hours.

For Healthcare System, the project aimed to simulate one of the surgical floors of the hospital specialist cllinic and using the floor layout of the proposed clinic and use the data from another clinic around the area. One of suggestions was asked patients went directly to treatment rooms for pre-consultation rather than went to unoccupied consultation rooms for pre-consultation.

The last speaker was Ir. Dr. Encon Y.Y. Hui (RPE) and his presentation topic named "Challenges of Facility Management in the Healthcare Industry". Firstly, Dr. Hui used P3 to explain Facility Management (FM). P3 was Plant x People x Process.

Then Dr. Hui introduced hospital facilities included HVAC, Piped Services, Electrical, Medical System. Those facility elements had their life cycle planning. The follow table compared some characteristics among FM in Hospital, Manufacturing and Malls & Offices. Finally, he introduce IE Way named ROW stand for Risk reduction, Outcome orientation and We as a team for Win-win. Dr. Hui also reminded us to rethink IE that less focused on hardware specific details, more focused on system & software or soft technology.

The Q&A session

Reference:

IIE(HK) - http://www.iiehk.org/

HKPC - http://www.hkpc.org/

- Project ROI, Technology testing and evaluation, RFID tags change-out schedule, Facilities and user interface design, Process flow design and Report creation

The Third speaker was Ir. Peter Chak (Customer Enquiries and Installation Services Manager, The Hong Kong and China Gas Company) and his presentation was “Inspection Robot for Gas Service Pipes”. Mr. Chak briefed the background of transmission of town gas. Then he explained why the risers got corroded because of building environment (e.g. Drainage pipes, Acid wash of external walls) and Hong Kong climate (High temp, Near saturation humidity, Sea-salt corrosion and Air pollutants).

Then Mr. Chak introduced the regular safety inspection for more than 1.75 million accounts and the cycle time was 18 months. But the low access rate during regular safety inspection (below 50%) and more than 50% risers were not able be inspected. Therefore, they developed Riser Inspection Robot with gas detector and camera which collected the image and leakage signals, then transferred by wireless system. The robot contained three system included Lifting system, Motion system and Inspection system. There were six classes of riser corrosion through vision inspection of the image taken. Moreover, Town Gas developed a Riser Health Index to monitor the healthiness of risers. Finally, Mr. Chak concluded they would development a comprehensive pipeline inspection system continuously.

Mr. Lam Wing-chiu (Terminal & Capacity Planning Manager, Modern Terminals Limited) was the fourth speaker and his topic entitled “Productivity Uplifting in Container Terminal”. Mr. Lam introduced the business of container terminal that they moved container boxes "to" and "from" container vessels to inland transportation. He said the container crane in horizontal level, indicating under operation. If the container crane left up, it mean the crane idle.

Reviewing the port statistics of top 10 container port in the world, Hong Kong was ranked second (after Singapore) since 2006 and then Hong Kong became the third port (after Singapore and Shanghai) since 2007. Shanghai overtook Singapore as the world's busiest container port in 2010. In 2012, The million TEU* of Shanghai, Singapore, Hong Kong and Shenzhen were 32.5, 31.6, 23.1 and 22.9, respectively.

(*The unit of container throughput is million TEU (Twenty-foot Equivalent Unit).)

The following diagram was comparison the throughput among Hong Kong, Shenzhen and Nansha. It could be confirmed Shenzhen would takeover Hong Kong in 2003 because of Dock Strike.

After that Mr. Lam introduced the "New Horizon" project in MIT aiming to improve operation performance and enhance productivity through changes three areas include Process Review, Technology Upgrade and Organization Realignment. The process would focus on Work flow review, Interviews, Time & Motion study and Activity log.

Mr. Harry Li (MD, Oriental Enterprise Management Solutions Ltd.) was the fifth speaker and his presentation was “Simulation Models for the Service Industry”. Mr. Li mentioned Simulation for Business allowed organization to "Experiment" using an accurate model before "flying the real thing" and allowed Businesses to Innovate profitably by enabling Low Cost "Serious Play".

Then Harry introduced several major applications of systems simulation in service industry such as Transportation, Airport, Call Centre, Financial, Insurance, Healthcare, and Logistics, etc. After that Harry shared his projects in Transportation System and Healthcare System.

For transportation system, the project objective was to simulate the flow of passengers in metro stations to identify bottlenecks and points of congestion during rush hours.

For Healthcare System, the project aimed to simulate one of the surgical floors of the hospital specialist cllinic and using the floor layout of the proposed clinic and use the data from another clinic around the area. One of suggestions was asked patients went directly to treatment rooms for pre-consultation rather than went to unoccupied consultation rooms for pre-consultation.

The last speaker was Ir. Dr. Encon Y.Y. Hui (RPE) and his presentation topic named "Challenges of Facility Management in the Healthcare Industry". Firstly, Dr. Hui used P3 to explain Facility Management (FM). P3 was Plant x People x Process.

Then Dr. Hui introduced hospital facilities included HVAC, Piped Services, Electrical, Medical System. Those facility elements had their life cycle planning. The follow table compared some characteristics among FM in Hospital, Manufacturing and Malls & Offices. Finally, he introduce IE Way named ROW stand for Risk reduction, Outcome orientation and We as a team for Win-win. Dr. Hui also reminded us to rethink IE that less focused on hardware specific details, more focused on system & software or soft technology.

The Q&A session

Reference:

IIE(HK) - http://www.iiehk.org/

HKPC - http://www.hkpc.org/

沒有留言:

發佈留言