“AI Impulse 2019: Catalyst to Business Succes” was

organized by Hong Kong Productivity Council (HKPC) on 17th - 18th

Jun 2019. Artificial Intelligence (AI)

is technology that significantly enhances productivity and operation

efficiency. There are two day event in

which day 1 is summit and day 2 is visit & AI workshop. I would like to

summarize day 1 on 17th Jun contents for sharing.

Photo

with EngD cohort Dr. Wing Hong SZETO

I

met Dr Shawn Zhao (Program Director, MIT-LTP) and took a photo for memory. I

believed CityU and MIT-LTP would be cooperated in near future.

Firstly,

Mr. Willy Lin GBS, JP (Chairman, HKPC) gave a welcome remarks. He thanks HKSAR

Government’s support on this AI Summit and HKPC Industry 4.0 (i4.0) and

Enterprise 4.0 (e4.0). He hoped that summit would be a catalyst for AI adoption

in the manufacturing industry in Hong Kong and the GBA.

Dr.

David Chung JP (Under Secretary for Innovation and Technology, HKSAR) was

honorable guest gave an opening remarks. He briefed I&T policy in Hong Kong

including advanced manufacturing, reindustrialization, InnoHK Clusters (Health@InnoHK

& AIR@InnoHK), and ITF, etc.

Signing

Ceremony of the collaboration between Tsinghua University and HKPC. There is

electronic signatory using fingerprint on two robots.

Group

photo

The

first keynote speaker was Mr. Andrew Hess (President, Prognostics and Health

Management Society, USA) and his topic entitled “Applications and Prospection

of Industrial AI for Prognostics and Health Management (PHM)”. Firstly, he quoted Mat Velloso interested comments

on the different between Machine Learning and Artificial Intelligence below.

i)

If it is written in Python, it is probably Machine

Learning.

ii)

If it is written in Power Point, it is probably

Artificial Intelligence.

Mr. Hess said the current logistics infrastructure to predict future health status was too large and costly. So that Prognostics and Health Management by using new technologies were a trend. He proposed structure as detection, isolation and prognosis.

The

concept of PHM aimed to detect “state changes” as far as possible from

Diagnostics to Prognostics.

He

concluded two PHM approaches were data driven (fit mathematical model &

statistics) and physics of failure model driven (basis of failure in model)

should be combined for better implementation. So that enterprise Big Data and

AI tools added capabilities on PHM.

Lastly, Mr. Andrew Hess showed some cases to explain how ML application

implemented in PHM.

The

second keynote speaker was Prof. Han Ding (丁漢)

(Academician, CAS; Dean, School of Mechanical Science & Engineering,

Huazhong University of Science and Technology) and his topic named “Future of

Robotics: The Tri-Co (Coexisting – Cooperative – Cognitive) Robots”. In the beginning, Prof. Han Ding pointed out

problems of robots in reality that Industrial Robots are poor online perception

and real-time operation, Service Robots are insufficient man-machine

cooperation ability, as well as, Special Robots relied on remote operations to

complete a specific task.

Then

Prof. Ding said the future robots should have the abilities to interact with

environment, with human and with other robots.

For Robot-Environment interaction, it would be walking robot and

continuum robot. For Robot-Robot

interaction, it could be individual autonomy and group collaboration. For Robot-Human interaction, it should be

safe and comfortable in structure and perception that understanding of the

human behavior (such as concept of i4.0 – CPS).

After

that Prof. Ding introduced Tri-Co Robots research which was launched by the

National Natural Science Foundation of China. Tri-Co Robots states for

“Coexisting-Cooperative-Cognitive Robots”. It aimed to fulfill the future

robots requirements and solve the robots’ problem. This research execution period is from 2017

to 2024 and total budget is 200M RMB.

Finally, Prof. Ding aimed to connecting “the last mile” of university achievements transformation. He briefed the HUST-Wuxi Research Institute R&D included high efficient machining for complex surface, robotic intelligent grinding system, robotic intelligent milling system, vision guide assembly robotic system, intelligent logistics & storage system, intelligent machine vision & measuring system, etc. So as to achieve government-industry-university-research-user deep integration.

The third keynote speaker was Dr Shawn Zhao (Program Director, MIT-LTP) and his presentation title was “A Glance of AI Research and Applications at MIT”. In the beginning, Dr. Zhao briefed the Kendall Square called the most innovative square mile in the world that many innovative companies surrounding the MIT included Google, facebook, apple, Microsoft, etc. MIT is a world-class research university and almost all departments are involved with AI related research said by Dr. Zhao.

Then

Dr. Zhao introduced the 1st AI Lab founded by John McCarthy and

Marvin Minsky named MIT AI Lab in 1959.

He also briefed MIT Media Lab which was founded in 1985 that is an

antidisciplinary research laboratory at MIT and its research groups included

neurobiology, biologically inspired fabrication, socially engaging robots,

emotive computing, etc. MIT Quest for

Intelligence was mentioned and many applications of AI in different departments

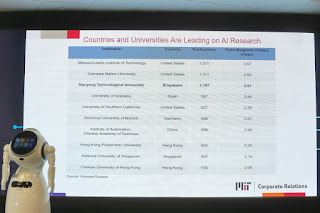

at MIT. The following two diagrams demonstrated

universities in countries/regions whose lead the AI Research. Hong Kong is the

third one!

PolyU

and CUHK are ranted within top ten!

And

then Dr. Zhao introduced MIT’s Industrial Liaison Program (MIT-ILP) in which

more than 250 world’s leading companies to be ILP members and 26% of them

sponsored MIT research, accounting for 49% of all corporate research funding.

One of key program named MIT Startup Exchange that actively promoted

collaboration and partnerships between MIT-connected startups and industry,

principally ILP members. Those startups

were based on licensed MIT technology or were founded and or led by MIT faculty

staff / alumni, so as to testing the commercial viability of new

technology. Lastly, Dr. Zhao stated the

trending technologies to us.

The

fourth keynote speaker was Dr. B Q Cui (Chief Architect and Vice President, AI

and Cloud Platform of Xiaomi) and his presentation named “AI and IoT support

Xiaomi’s Sustainable Innovation”. Dr.

Cui firstly briefed their AI problem named Xiaomi music box.

Then Dr. Cui introduced Xiaomi’s capability graph included business, platform, application, cognition and foundation. He also briefed their strategy on IoT since 2014 that most of collaboration products using Xiaomi Wi-Fi modules. Unit now, Xiaomi had 2000 types of product connected and more than 1300 companies cooperated together.

After

that Dr. Cui stated Xiaomi music box had AI language assistant to connect

different hardware and control different electronic products.

Finally,

Dr. Cui mentioned the Xiaomi strategy on double engine – Mobile and AIoT. He

shared their open ecosystem at the end.

The

fifth keynote speaker was Prof. Jay Lee (Director, NSF I/UCRC on Intelligent

Maintenance System (IMS) and Vice Chairman of Foxconn Industrial Internet) and

his topic was “Industrial AI and Industrial Internet of Thing for Smart

Manufacturing”. His speech topics would include industrial internet

transformation, industrial AI & Big Data, Smarter Manufacturing Lighthouse

Factory and transformation case studies.

Firstly,

Prof. Lee mentioned industrial transformation from 1950 to 2000 through quality

and six sigma. Now, it could be

transformed by Industry 4.0 and Industrial Internet.

Then

he told us the three fundamental elements of digital transformation were

People, System and Things. The core

technologies applied were Data Technology (DT), Analytics Technology (AT),

Platform Technology (PT) and Operations Technology (OT). He always mentioned ABCDE stated for

Analytics (AI), Big Data, Cloud, Domain Knowhow and Evidence.

After that Prof. Lee introduced opportunity for intelligent system through visible to invisible and solve to avoid problem that the value creation using smarter information for unknown knowledge in the invisible and avoid region.

Prof.

Lee also introduced 3D of industrial big data and they were Broken Data, Bad

Data and Background Data. He said Data

Quality is very important that the Data Quality Evaluation System should be

established. He said that “Industrial

AI, is a systematic discipline which focuses on developing, validating and

deploying various machine learning algorithms systemically and rapidly for

industrial applications with sustainable performance.”

Finally,

he stated using Industrial AI tools depended on four element in axis that were

uncertainty and precision, as well as, speed and complexity. The industrial AI System structure were

demonstrated. Lastly, he briefed their

Lights Out Factory and discussed current challenges to find AI Talents. So that they established Industrial AI

Institute (https://www.iaiinstitute.com/).

Afternoon

Parallel Session, I joined the session I and summarized as follows.

The

first session speaker was Mr. Ian Fountain (Director, Technical Marketing –

Industrial Internet of Things of National Instruments) and his presentation

title named “Better Outcomes start with Better Data”. He said the most of your engineering

investments would be on 5G, IoT and Automotive.

The Mr. Fountain briefed IoT Value Streams which started from Data. The following IoT trends could improve data such as Wireless Communication, MEMS Technology, Edge Processing and AI/Analytics/ML.

Edge

Processing that choose where the ‘math’ happens and stop waiting for data to

make a round-trip to cloud and back.

Therefore the data throughout was much higher (e.g. 1.6TB/Day).

Lastly,

Mr. Fountain mentioned Asset Health Maintenance using different mathematical

approach under different asset criticality level and obtained different

insights.

The

second session speaker was Mr. Haisheng Yang (General Manager, ZPMC Smart

Solutions Group) and his topic entitled “Smart Equipment on Cloud”. Mr. Yang introduced China Communications

Construction and Shanghai Zhenhua Heavy in the beginning. It included Port Machinery, Smart System,

Smart Operation & Maintenance and Planning & Simulation.

Then

he discussed the following questions.

1. Why

we need Smart Equipment on Cloud?

2. What

we can do on Cloud for Smart Equipment?

3. What

we have done on Cloud for Smart Equipment?

4. What

we will do on Cloud for Smart Equipment?

The

following diagram demonstrated their smart equipment connected on cloud.

Finally,

he concluded procedural work would be increasingly done by machines that let

people be human and machines works.

Ports would be automatic and smart using AI and cloud computing.

The

third session speaker was Ms. J Y Li (Product Director, TCL in Intelligent

Manufacturing Products) and her presentation title named “Applications of AI

for Smart Manufacturing and Intelligent Inspection”. Firstly, Ms. Li briefed

TCL semiconductor’s factory and then introduced AI application and expectation.

Ms.

Li briefed the process flow from product design, parameter design to failure mode

predication. AI was employed and reduced

the R&D cycle to 30%.

And

then she quoted one of application on AI for product defect inspection that

could reduce the inspection cycle to 60%.

Finally,

Ms. Li expected big data and AI algorithm could enhance smart manufacturing

based on Descriptive, Diagnostic, Predictive and Prescriptive level.

The

last session speaker was Mr. Ken Law (Founder and CEO, Motherapp) and his

presentation topic was “AI to Boost Smart Business”. He briefed industry 4.0 history and how AI

employed in the traditional industry.

Then

he demonstrated some cases they done for assembly line balancing using AI

vision recognition and ML.

Mr.

Law also showed another example in textile industry for sewing line real-time management

and calculated the overall process effectiveness (OEE = Availability x

Performance x Quality x Safety).

Forum

on Adoption of AI for Manufacturer and Enterprise

Mr.

Edmond Lai (Chief Digital Officer, HKPC) was the moderator. (Left one)

(Guests

from Left: Prof Yuexian Zou, Prof Tao Zhang, Dr. B Q Cui, Mr. Andrew Hess, Dr.

Shawn Zhao, Dr. Christian Maase, Mr. Paul Wu)

Mr.

Edmond Lai asked guests comments on AI + Industry.

Mr.

Paul Wu suggested using new business model to create demand because ecosystem

is changing.

Mr.

Andrew Hess use one word that was PHM.

Dr.

Zhao said MIT always supported industry using AI.

Dr.

Cui said AI and industry in China had a great opportunity because we had a lot

of data, local AI companies and young talents (especially Engineer).

Prof.

Zou said AI for Fintech and trading market were important.

Mr.

Edmond Lai asked guests about how to keep and train AI talents.

Mr.

Andrew Hess suggested to use the title data scientist rather than engineer and

trained them in multi-discipline subject.

Mr.

Paul Wu encouraged young talent didn’t look down yourself.

Prof.

Zhang said education system should be changed and taught young people AI.

Prof.

Zou added there were 35 universities in China had a new degree program in AI

major.

Dr.

Cui said it was hard to build data scientist team several years ago. University should encourage faculty member to

train young professional in AI. Keep

professors in university and didn’t let them all jump into industry!

Mr.

Edmond Lai asked the last question about Future AI and giving suggestion to

HKPC.

Mr.

Paul Wu suggested to enhance AI application in Industry. Service robot and special robot could change

our life to next level.

Prof.

Zou said Hong Kong had a good foundation to develop AI in medical and finance

field.

Prof.

Cui said Hong Kong should keep open and attract more top professional in the

world. He said Xiaomi changed from

data-driven to AI-driven.

Dr.

Zhao suggested we thought why great company like Sense Time in Hong Kong why not

in other place. How HK to achieve AI in industrial application. How to maximize

AI research result and ecosystem?

Reference:

沒有留言:

發佈留言