In the beginning, Mr. Leung Kwan Yeung (Chairman – Vocational Training Council (VTC)) gave an opening address. He said the VTC would provide more short term training courses and workshops for testing and certification industries based on the report of Hong Kong Council for Testing and Certification (HKCTC).

.JPG)

The first keynote speaker was Ir. Raymond Wong (Consumer Testing Services Director, SGS Hong Kong Ltd.) and his topic was “New Outlook, New Opportunities Insider’s Look into Testing & Certification Industry”.

Ir. Raymond Wong speech included four topics. They are:

New era – Testing & Certification Industry (T&C) as one of the 6 economic areas with clear advantage;

New factors – Success story of a global brand;

New evolution – From last 50 years to next 50 years; and

New trend – Sustainability defines our future.

He said that SGS would cooperate with VTC, and they focused in Traditional Chinese Medicine (TCM) and provided GMP training.

He explained the success of SGS based on TRUST. It included “NETWORK” , “EXPERIENCE”, “RESOURCES”, “EXPERTISE” and “COMMITMENT”.

Then SGS service values in 3Ps perspective were introduced. They are “Profit”, “People”, and “Planet”. In “People”, SGS had “Management Development Program” in which 30 staffs were selected for training to be middle management level in mainland universities per year, so as to develop a talent pool.

The second Keynote speaker was Mr. Harry Yeung (Chief Operating Officer, Hong Kong Standards and Testing Centre) and his speech entitled “Hong Kong Product Certification Program Development”.

Mr. Harry Yeung said Hong Kong lack of product certification scheme compared with other developed countries’ schemes such as UL, VDE, GS, etc. However several existing regulations were effective in Hong Kong included toys safety (1993), consumer product safety (1995) and electrical product safety (1998).

Hong Kong Safety Marks established in 1998 which followed ISO Guide 65. It aims to enhance the product quality in industries and promote product safety to public.

Hong Kong Safety Mark Product Certification flow was introduced

“STC tested” Mark

Some products were achieved “STC tested” Mark such as consumer product regulation (1995), Chinese Medicines (2003) and Nutrition Label (July 2010).

He said that the following points were focused for future development.

i) extension of product certification scope

ii) enhancement of the international mutual recognition

iii) promotion of Hong Kong Safety Mark and “STC tested” Mark to worldwide

iv) following 6 pillar industries direction

The third keynote speaker was Mr. P.C. Chan (Chief Operating Officer, Hong Kong Quality Assurance Agency (HKQAA)) and his topic entitled “Value-added certification through quality audit”.

He shared the seminar of CNCA, CNAS and CCAB in China. The main focus of that seminar was the risk of certification industry between professional and commercial. And he briefed how to enhance recognition of the certification. Moreover, He mentioned ISO 9001 was a good tool for improvement and the future plan was about “Beyond Surveillance Plan”.

Then, the first discussion panel was moderated by Dr. Christopher Leung (Academic Director (Applied Science), Vocational Training Council). During the discussion, all guests agreed “Integrity” was the most important element in the Testing and Certification Industry. Therefore, it should be included in training courses.

Photo with speaker (Mr. P.C. Chan) and friends

(Left: Ms. Joyce Chan (Acting Senior Lecturer, VTC), Mr. Steve Chan (Head of Operation and Training Business, BSI), Mr. P.C. Chan (COO, HKQAA) and I (Quality Manager, HKSTP))

(Left: Ms. Joyce Chan (Acting Senior Lecturer, VTC), Mr. Steve Chan (Head of Operation and Training Business, BSI), Mr. P.C. Chan (COO, HKQAA) and I (Quality Manager, HKSTP))After coffee Break, parallel sessions were started. I selected to attend Session II about Laboratory and Certification Accreditation.

Dr. W.T. Tang (Accreditation Officer, Hong Kong Accreditation Services) was the fourth speaker to present the topic “Laboratory Accreditation on Chemical Testing”. He said that Accreditation Body was authorized by government (or otherwise recognized by stakeholders) which operated according to ISO/IEC 17011.

Dr. Tang introduced the laboratory accreditation flow. He also briefed the measurement traceability in chemistry. The SI unit is mole (mol). Moreover, he mentioned the certified reference materials should be supplied by recognized national institute (e.g. NIST) in which reference materials producer (RMP) should be accredited to ISO Guide 34 and ISO/IEC 17025 in combination.

For Non-Standard method, validation of testing method and measurement should be performed before use. The definition of Validation, Verification and Objective evidence were shown as follows.

- Validation is the confirmation by examination and provision of objective evidence that the particular requirements for a specific intended use are fulfilled (ISO/IEC 17025 clause 5.4.5.1 & ISO 8402:1994)

- Verification is the confirmation, through provision of objective evidence, that specified requirements have been fulfilled (ISO 9000:2000).

- Objective evidence is data supporting the existence or verity of something (ISO 9000:2000).

The following slide showed the requirement for verification or validation in different method types.

The quality control plan for monitoring the validity of results on chemical testing were discussed such as blank, spiked samples, control samples, replicates or duplicates, inter-operator comparison, inter-laboratory comparison and comparison using different techniques.

Mr. K.W. Chen (Senior Accreditation Officer, Hong Kong Accreditation Services) was the fifth speaker and his topic was “Certification and Laboratory Accreditation”.

Mr. Chen introduced the HKAS structure and explained the feathers of product certification. Production certification was issue of a statement (certificate) by a third-party (certification body), based on a decision following review that a product’s fulfillment of specified requirements (product certification scheme) had been demonstrated (by supplier).

The following slides showed the product certification systems under ISO/IEC Guide 67:2004.

At the end, Multilateral Recognition Arrangement of Certification Body was introduced.

During the lunch, Mr. Fong represented Hong Kong General Chamber of Commerce (香港總商會) to give a speech. He said there were three competitive edges in Hong Kong.

i) Established Hong Kong Testing & Certification Brand

ii) Shared the most updated information about the industry

iii) Supported SME by government organizations such as HKPC, VTC, etc.

Professor P.C. Ching (Chairman, Hong Kong Council for Testing and Certification (HKCTC)) gave an honour address. He shared HKCTC vision “Hong Kong to develop into a testing and certification hub in the region by reinforcing the branding of “Tested in Hong Kong, Certified in Hong Kong”.

The first keynote speaker in afternoon session was Mr. Dominic Lam (General Manager, CMA Testing and Certification Laboratories) and his presentation title was “Testing and Certification Industry – Manpower Requirements and Career Opportunities”.

Mr. Dominic Lam said that about 15690 persons engaged in the industry in which 9090 (58%) were professionals and associate professionals whose main duties were to carry out testing, inspection and certification services, where 50% had university degree or above, 33% had higher diploma or diploma / certificate, and 17% for others.

He said it needed about six month on-the-job training for new recruits. (In my experience, I joined CMATCL as QA officer in that post I used 3 month to familiar all calibration works and used another 3 month to familiar all QA related jobs including IQA, Proficiency testing / interlaboratory comparison arrangement, etc.)

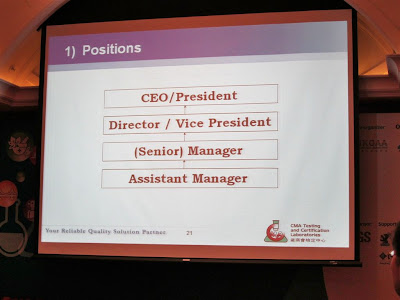

The following career path was stated.

He also pleasured VTC to provide HD courses and part-time upgrading courses that were highly relevant to the industry. Then professional Recognition Program proposed by Hong Kong Testing, Inspection & Certification Association (HKTIC) was introduced. The program aimed to encourage young professionals entering into the T&C industry, benchmarking in recruitment and improving professional image of industry.

Lastly, he concluded Passion and Curiosity were the most important elements in the career planning (which more significant than IQ) of Testing and Certification Industry.

The second Panel discussion was moderated by Dr. Lawrence Chan (Academic Director (Engineering), Vocational Training Council). Some audience questioned the cost of SME would be increased if testing items increased by regulation. Prof. Ching said it needed a balance. Increasing testing requirements may be caused by increasing living standard such as food and Chinese medicine.

Photo with Dominic Lam

(Left: Ms. Joyce Chan (Acting Senior Lecturer, VTC), Dr. Christopher Leung (Academic Director, VTC), Mr. Dominic Lam (GM, CMATCL) and I (Quality Manager, HKSTP))

(Left: Ms. Joyce Chan (Acting Senior Lecturer, VTC), Dr. Christopher Leung (Academic Director, VTC), Mr. Dominic Lam (GM, CMATCL) and I (Quality Manager, HKSTP))After that I joined the Session IV in the afternoon parallel sessions. Mr. Ronald Lau was the second speaker and his presentation entitled “Recent Developments of Food Testing in Hong Kong”.

He said that an opportunity for testing and certification in food industry after nutrient labeling regulation was effective on 1 July 2010. The number of testing items was estimated to be as high as 2 Million. Moreover, food safety was also focused in mainland and Hong Kong testing industry had potential to provide service in mainland China.

He also introduced some food related certification schemes such as HACCP, ISO 22000 and HKQAA – HCS “Hygiene Control System”. Finally, he concluded the advantages in Hong Kong such as equipment, manpower, cost (it is not advantage, so it must be value-added service), integrity and brand, as well as, one-stop shop service and value-added service.

The last speaker was Prof. Zhao Zhongzhen (Programme Director of BPharm/CM Hong Kong Baptist University) and his topic was “Testing of Chinese Medicine”.

In the beginning, he explained the classification of different types of Chinese Medicines. Why it was important to identify the right Chinese medicine? People would be poison if wrong identification of CM used.

The case of Wuhuacha composition was shared. If one of flowers misused such as “Datura metel L.”, people would be poison.

Many confused CMs in Hong Kong were introduced.

Prof. Zhao introduced 2006 NIH Policy Requirements on Quality of Natural Products for Research as follows.

- Source of materials must be identified

- Plants must be authenticated

- Analysis to rule out contamination must be done.

The Hong Kong Chinese Materia Medica (CMM) Standard was established.

Then he mentioned the facilities / equipments in “Bank of China (Hong Kong) Chinese Medicines Centre”.

DNA Molecular Marker Authentication would be more popular for identifying CMM.

He explained how to select a high quality “杞子” at the end.

Lastly, Dr. Michael Lam (CEO, Hong Kong Quality Assurance Agency) gave a closing remark.

i) Understand your customer need

ii) Be Professional

iii) Integrity & Trust

For more information:

http://www.vtc.edu.hk/vtc/web/template/event.jsp?fldr_id=1031&content_id=15658

For more information:

http://www.vtc.edu.hk/vtc/web/template/event.jsp?fldr_id=1031&content_id=15658

沒有留言:

發佈留言