The International Academy for

Quality (IAQ) is an independent, self-supported, non-profit, non-governmental

organization that is administered by a collegial assembly of individuals who

have been elected by their peers form among the most respected, active and

experienced protagonists of quality in the world. In 2017, the 61th EOQ Congress would be a

joint effort of European Organization for Quality (EOQ) and the Slovenian

Quality and Excellence Association as well as IAQ in Bled, Solvenia from 11 to

12 Oct 2017. One day after the Congress,

on 13th Oct 2017, the 2nd IAQ World Quality Forum was

held at the same place. The theme of the

2nd IAQ World Quality Forum is “Future Impact of Quality”. I would like to summarize the forum below for

sharing.

Mr. Janak Mehta mentioned we met

a tremendous opportunity in big data, Industry 4.0 and IoT.

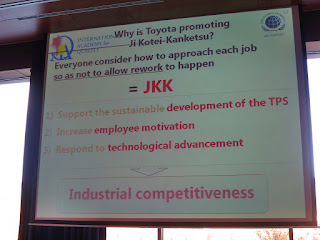

Then he shared Toyota’s Ji

Kotei-Kanketsu (JKK) that everyone considered how to approach each job so as

not to all rework to happen. It was the

built-in Quality in process with accountability.

Finally, Mr. Janak Mehta

summarized that we needed with head in the cloud and feet on the ground; and

contributing to build in quality in design, production and delivery of error

free products and services that customers could use with confidence through

motivated and capable people.

Dr. Pal Molnar (IAQ President)

chaired the opening and introduced the keynote speaker.

Mr. Gregory H. Watson (Honorary Member of IAQ, USA/Finland) was the first keynote speaker and his topic entitled “Feigenbaum Memorial Lecture – Intergalactic Quality: Reaching for the Stars Beyond our Imagination”. Firstly, Mr. Watson reviewed for a half century quality had south gurus. The guru’s ideas served their time well, but they were not able to meet challenges of a digital age.

Then Mr. Watson mentioned the

emerging nature of quality and reviewed the basic quality concept prior WWII

including Hypothesis test, LSR, SQC, DoE, QMS, Reliability, Problem Solving,

etc. He pointed out the technology was advancing

faster than the quality science. Then he

explained the industry maturity corresponded to quality below.

Industry 1.0 -> Quality 1.0 =

Inspecting each and every important output to assure quality

Industry 2.0 -> Quality 2.0 =

Inspection-based quality has an emphasis (AQL) and Labor-based performance is

measure of productivity

Industry 3.0 -> Quality 3.0 =

Standardizing work, satisfying customer and continual improvement

Industry 4.0 -> Quality 4.0 =

Digitization is a critical ingredient in process optimization. Self-induced correction and machines learn

how to self-regulate and manage their own productivity and quality.

After that he discussed the

traditional definition of quality about under-quality and over-quality

condition. However, the definition was outdated because Quality is not a “Red

line” that is drawn in the sand. Gregory H. Watson (2016) defined that Quality

– the persistent pursuit of goodness coupled tightly with the simultaneous

relentless avoidance of badness.” And “The final arbitrator or judge of quality

is the customer.” As well as, “Quality maximizes the value proposition.”

Finally, he discussed about Productive

System (PS) working mechanisms that were Integration of things and people also

called Industry 4.0 that optimizes operation of Internet of Things (IoT). Data analysis must generate profound

knowledge which contributed by Big Data, AI and Collaborative Analytics. Finally, he showed the generic system of

managing for quality. He also quoted

Yoshio Kando that “Stimulating people’s desire to work is motivation” to

demonstrate the Leadership enables followership.

During the tea break, we had

coffee and discussion with many IAQ friends.

I took a photo with Mr. Glenn

Mazur and Dr. Ayed Alamri.

Dr. KS Chin and I took a photo

with old friends.

(Left: I, Dr. KS Chin, Mr.

Juhani Anttila, Mr. Deng Ji and Dr. Ayed Alamri)

I met Shanghai Quality

professionals.

(Left: Mr. Deng Ji, I, Ms. Liu

Zhuohui (劉卓慧)(President, China Trade Association

for Anti-Counterfeiting), Mr. Gao Feng (高峰) (Director, Customer

Evaluation Center – An Affiliate of SAQ), Ms. He Xianglian (賀湘煉) (Deputy Director,

Dept., of Q&S Mgt, SPIC) and Ms. Zhen Minwei (甄敏蔚) (Chief Editor, Shanghai Quality Magazine Publishing House))

I met Prof. Azat Abdrakhmanov.

Then Dr. KS Chin and I joined

the STREAM B1 session named “Industry 4.0 and Big Data”.

The first speaker was Mr. Thomas

Prefi (WZL RWTH Aachen, German) and his presentation topic was “Quality 4.0 –

What Will Matter!” He briefed the

digital agenda to discuss which innovation tool had to be utilized to master

Industry 4.0 and pointed out the following challenges for quality:

i)

Changing the perspective: From

product to ecosystem!

ii)

The supplier structure

change: From a traditional value chain

to network!

iii)

The way how to develop a

product is changing: Products are developed in agile environment.

iv)

How does “perpetual beta“ and

“good enough quality” fit with the German attitude to perfection!

Then Mr. Thomas Prefi mentioned

the six essential tasks of the Q-Organization.

He described the traditional V-model and questioned that it was becoming

obsolete when it became agile. He said

“Quality principles are still valid but methods are not fit anymore!” And then he proposed the new tools for QM

such as 72h-radar which was consolidating of the data between suppliers,

logistics and the customer.

Finally, Mr. Thomas Prefi

discussed the machine learning. He said

machine learning would not replace people in QM but force us to

development. It created at least two

jobs for quality professionals that one was mentor for machine training and the

other was curator for validation. That’s

what he concluded about Quality 4.0 and Organization 4.0 to put the world in

boxes!

Dr. KS Chin (Associate

Professor, SEEM Dept., CityU) was the second speaker and his presentation title

named “Quality Analytics for Quality and Performance Improvement”. He introduced the data analytics in the

beginning that “It is an emerging technique that drives into data set without

prior formulation of hypotheses. It is

the process of examining data sets in order to draw conclusions about the

information they contain.” Then he

pointed out some application example such as social media analytics tools

(Twitter & Facebook)

After that Dr. Chin mentioned

the relationship of Analytic and Quality Management and quoted Prof. Sung Yung

Park presentation at ANQ 2017 that quality experts should be Data Scientists.

And then Dr. Chin added that data analytics driven quality management through

performance analytics and predictive analytics.

Finally, Dr. Chin introduced the

quality analytics process model for “data to value” which could be separate

from “data-to-insight” and “insight-to-action” process. He also shared his research employed data

analytics named “Quality Improvement in Healthcare Service”.

At the end, Dr. Chin introduced

the Education related to Quality Analytics that CityU revamped BEng Total

Quality Engineering program and MSc management program with data

analytics. The details of modules were

showed and discussed.

The third speaker was Mr. Shentu Jun (China) and his topic entitled “Intelligent Digitalized Design with Effective Quality Improves Efficiency”. Firstly, he introduced his quality journal in SNERDI Quality System in R&D which was based on different standards included HAF003/HAD003, IAEA GSR Part 2/GS-G-3.5/50-C/SG-Q, ASME NQA-1, ISO 9001, ISO14001 and OHSAS 18001.

Then he introduced Intelligent

Digitalized Design (IDD) with quality improved efficiency through rules made,

process optimization, method R&D, Data-aid work and Data Management. Finally, he summarized for sustainable

development of the techno-economy, safety based on quality is very

important. Data model, data quality

management, data collection & application was crucial for digital design.

The last speaker of the session

was Mr. Deng Ji (Shanghai Academician For Quality Management, China) and his

presentation title was “Quality and Modern City”. He firstly briefed the background of the

National Model Cities of Quality which campaign had organized and carried out

by the General administration of Quality Supervision, Inspection and Quarantine

of P.R.C. since 2012.

Then Mr. Ji discussed each major

requirement for the building of “National Model Cities of Quality” included

“Quality culture construction”, “City brand cultivation”, “Focus on citizens’

life” and “Performance appraisal of quality progress”. He also made reference to ISO 37120 World

Council on City Data which allowed us to explore, track, monitor, and compare

member cities on up to 100 service performance and quality of life indicators.

In Q&A session, Dr. Chin

explained his new course related to data analytics to the participants.

At the end, Prof. Kano gave some

comments on that session. He used Japan

nuclear plant accident to explain the one mistake affected the environment

seriously. Could we use big data and

industry 4.0 to overcome safety issue systematically?

After that I prepared my

presentation in the STREAM C2 Session which chaired by Prof. Hans-Dieter

Seghezzi.

The first speaker in this

session was Prof. A. Blanton Godfrey (College of Textiles, North Carolina State

University, USA) and his presentation title named “Driving Innovation and

Entrepreneurship”. Firstly, he briefed the definition of Entrepreneurship and

Disruptive Innovation.

Then Prof. Godfrey briefed their

research database on entrepreneurship as well as the need of entrepreneurs such

as Space, Internet, Air Condition and Coffee.

What kind of space do entrepreneurs need? They just needed a table and

two chairs, wet lab, tool shop, wine & cheese bar and music. Extra needs of entrepreneurs were Money,

Mentors, Adult Supervision, Network and a Place to Live. Finally, he introduced their Center for

Technology and Innovation.

The second speaker was Mr. N.

Ramanathan (India) and his topic entitled “Redefining Organization

Performance”. He reviewed the past

business leaders argument and the impact between profit and society. Drucker’s performance metrics was found to

like the first balanced scorecard.

The shorten history of judging

business performance was discussed.

Finally, Mr. Ramanathan

concluded that financial performance did not equal to organization

performance. He proposed the redefined

organization performance model required a linked combination of capability-building

and effects, as well as, care planet earth.

The third speaker was Mr. Janos

Takacs (VP Communication, Hungary) and his presentation named “CSR and

Sustainability – From Milton Fredman to Michael Porter and beyond”. In the beginning, Mr. Takacs briefed the

Fredman Doctrine’s shareholder approach to Porter & Kramer’s CSR Value

Chain. He then explained that CSR

coverage was larger than Creating Shared Value (CSV).

Then Mr. Takacs mentioned EFQM

included CSR and Quality Management and they had strong correlation.

Prof. Hans-Dieter Seghezzi introduced my background at the end of this session.

I (Lotto Lai) (Associate

Academician of IAQ; Chairman of HKSQ) was the last speaker and my topic

entitled “Quality Innovation: Extenics Employed in Quality Startup Management

System”. My content included Quality Innovation and its trends; TRIZ and

Extension Innovation Method, Quality Startup Management System (QStarMS) and

Extenics applied in QStarMS.

I briefed the history of quality

management and innovation tools development.

I compared their timeline and found that they had strongly

complementary.

Then I introduced Prof. Cai Wen

and his innovative philosophy named “Extenics” which had been studied since

1976. His important paper named “Extension

Set and Incompatible Problem” was published in 1983. It aimed to solve contradictory problem

through extension possibility of things.

After that I briefed my Quality

Startup Management System (QStarMS) model which combined that simplified ISO

9001 requirement, plus HKSTP incubatee milestone assessment and business model generation, as

well as, HKQAA 25 questions.

For new business model

generation, I introduced the Extension Innovation Four Steps Methodology named “Model”,

“Extension”, “Transformation” and “Selection” (METS) to change the existing

business model to more possible new businesses. (e.g. Discount Taxi, Uber, Ofo,

GogoVan, Airbnb, etc.)

At the end, I concluded that “Extenics”

is a good innovation tools to help quality professional from thinking inside

the box to outside the box systematically, so as to create many ideas like idea

factory and provided ideas pipeline for new product/service, and new business

model use.

During Q&A session, I

explained more about Extenics divergence of the Extensible analysis. I believed that part of Extenics using

basic-element format could create as much idea as possible for everyone without

science and engineering prerequisite.

We met Prof. Kano and had lunch

together. Dr. Ivan Ng (our coopt member)

had presented in the other session at the same time of my session. His topic named “An Analysis of the Impact of

Chinese Cultural Factors to Quality Management by Six Sigma”.

After lunch, I joined the STREAM

C3 session named “Future of Quality Management” which chaired by A. “Parsu”

Parasuraman (USA).

Mr. Juhani Anttila (Academician,

IAQ; and member of ISO TC 176, as well as Former President of the Finnish

Society for Quality) was the first speaker and his topic was “Out of the Crisis

of the Quality Profession: The New Renaissance in the Quality Discipline”.

(P.S. We

had dinner with Mr. Juhani Anttila in Hong Kong in 2015.) He raised two examples to demonstrate the

crisis that one was unclear terminology leads to pseudo results in research

projects and the other was “the quality imperative” in education was of a great

consensus, but the quality as a concept was unclear.

Under

technological achievement and urbanization, quality profession should reform to

get quality happen in practice. Because of the fragmentation of QM

practices under many tools (tool-fragmented), it caused comprehension of the

whole lost. So Mr. Juhani Anttila suggested the solution to the crisis

that was renaissance of the quality profession on two levels below:

i)

Theoretical and scientific of the quality

discipline – The renaissance in thinking

ii)

Quality Integration – The renaissance in practice

At the

end, he pointed out three challenges to the quality profession for the quality

renaissance.

i)

Quality and QM of individuals – Quality of

life

ii)

Quality and QM for the society – Quality of

society (including Industry 4.0 & Smart City)

iii)

Quality management in SMEs and startups

The second speaker was Mr.

Bension Tendler (Canada) and his topic named “Looking backwards in History to

Look Better Further in the Future”. Mr.

Tendler reviewed the management and business history from different countries

included USA, UK, Germany, etc. (Except

Japan because of well-known)

Mr.

Tendler said WWII as catalyst to develop sampling inspection for the goods and

standards for process control. Then Leslie Simon was active in the founding of

the ASQC in 1946. Lessons to be learned from this history were:

i)

Appreciation of history help in planning and

decision making;

ii)

Planning of national movement require an

understanding of national culture and background;

Mr. Glenn Mazur (QFD Institute, USA)

was the third speaker and his presentation topic entitled “Prioritization

Methodology for Quality Professionals using ISO 16355 Guidance”. He discussed how could we best apply the

criteria to prioritize and selected the best options through ISO 16355-2:2017,

cls 9.1.2.8.4 for step-by-step guidance.

Mr. Glenn

Mazur said executive decisions often required judgment by intelligence, design

and choice. He questioned that could we better leverage insight,

experience, and intuition? There had limitations of ordinal judgments

because people had bias on pessimists score lower end, or optimists score higher

end, or unsure score the center. He then introduced four types of

criteria for measuring judgments below.

i)

Counts, bigger is better

(Objective)

ii)

Counts, smaller is better (Objective)

iii)

Absolute or expert judgment (Subjective)

Finally, he demonstrated those

judgements and employed Analytic Hierarchy Process (AHP) pair-wise comparison

for project priorities. Mr. Glenn Mazur

concluded that AHP was able to use for prioritizing projects, customer

segments, customer needs, technology options and suppliers.

Then I joined the STREAM B3 to

attend Dr. Ayed Alamri (Saudi Arabia) and his presentation title was “The

Leadership Role of Saudi Quality Council”.

Since their session ran faster, I only join the discussion part. I would like to know the relationship between

Saudi people culture and leadership.

During the tea break, I took a

photo with Singapore friend Mr. Singh Harnek.

Took a photo with Chinese friend

Mr. Shentu Jun.

Oh! Ms. Liu Zhuohui (CAQ) played

the piano.

I met Mr. Paul Harding (Executive

Director at South African Quality Institute) and Prof. Azat again.

Closing Plenary Session

The final keynote was Prof.

Noriaki Kano (Honorary Member for IAQ and ASQ) and his topic entitled ‘Ishikawa

Memorial Lecture – Intranet of Qualities (IoQ) for Quality Assurance in the

DIGITAL ERA”.

Firstly, Prof. Kano introduced

his teacher Mr. Kaoru Ishikawa and his book named “The Man and Quality Countrol”

which had translated into English at http://www.juse.or.jp/english/archives/

.

Then Prof. Kano said under IoT,

we ubiquitously utilize ICT. IoT brings

about big data and then we needed to make its analysis. So almost all the data related to QA is

confidential to outside of a company so that Intranet (close IoT) is used. Then he discussed the data for quality

assurance in R&D applying QFD. However, the quality table became too large!

After that Prof. Kano stated the

data for QA in Manufacturing using QA Matrix.

The following diagram showed the hierarchical structure of In-Process

Control through three tiers included Product, Process and Work. Prof. Kano said the 21st Century

would be an age of thorough application of “Build Quality in Process (BQiP)”. It also created Butterfly Model (Butterfly

effect!)

Prof. Kano added to develop IoT

to link various data of qualities for QA such as Customer Requirement, Product

Specifications, Component Specification, Process Parameters, SOP, Testing

Characteristics, Inspection Items, etc. He

introduced Intranet of Qualities (IoQ) as following diagram.

Prof. Kano reminded us care

about the analysis the correlation data. It should find the causal relationship

before making the conclusion. (It could be pseudo-correlation!)

Finally, Dr. Pal Molnar (IAQ

President, Hungary) gave the closing remark.

Reference:

20171012&13:

The 2nd IAQ World Quality Forum – Welcome Cocktail and Dinner - https://qualityalchemist.blogspot.hk/2017/10/the-2nd-iaq-world-quality-forum-welcome.html

20171013:

The 2nd IAQ World Quality Forum 2017 in Bled, Slovenia - https://qualityalchemist.blogspot.hk/2017/10/the-2nd-iaq-world-quality-forum-2017-in.html

The 1st IAQ World Quality

Forum 2015

20151025:

IAQ World Quality Forum 2015, Hungary – Welcome Cocktail - https://qualityalchemist.blogspot.hk/2015/10/iaq-world-quality-forum-2015-hungary.html

20151026:

IAQ World Quality Forum 2015, Hungary – Day 1 - https://qualityalchemist.blogspot.hk/2015/10/iaq-world-quality-forum-2015-hungary_26.html

20151027:

IAQ World Quality Forum 2015, Hungary – Day 2 - https://qualityalchemist.blogspot.hk/2015/10/iaq-world-quality-forum-2015-hungary_27.html

沒有留言:

發佈留言