The seminar on "Safety Management and Risk Assessment in Railway Operations" was organized by Hong Kong Society for Quality (HKSQ) and co-organized by American Society for Quality (ASQ), Department of Systems Engineering and Engineering Management (SEEM) of CityU and Institute of Railway Signal Engineers (IRSE) - Hong Kong Section on 24 Feb 2012. With the advent of new technologies, the international enhanced safeguards for passengers. The seminar aimed to provide participants with an updated view on contemporary policies and practices of safety management and risk assessment in railways operations.

In the beginning, I am honour represented HKSQ to gave welcome speech. I appreciated to all speakers and co-organizers. Then I briefed the objectives of HKSQ and introduced the coming ANQ Congress 2012. Finally, I pointed out two crises which were Fukushima Daichi Nuclear Power Station accident on 12 April 2011 and Wenzhou High Speed Train crash on 23 July 2011, indicating the important on safety management and risk assessment.

And then Prof. Kwok Tsui (Head of SEEM, CityU) gave a welcome speech. He presented the engineers' view on safety management and risk assessment.

The first speaker was Mr. KW Pang (Infrastructure Maintenance Manager, MTR) and his topic entitled "Safety in the Railway Industry".

Mr. Pang briefed some railway accidents occurred in the past.

He explained why safety of railway was very concerned by public. It was because Railways carried over 4M passengers per day in Hong Kong. Railway safety would become more high profile and sometimes political. Some photos about passenger behavior in the old days Hong Kong were shown.

After that Mr. Pang introduced the major railway safety concerns as follows:

FIRE, Equipment Failure, Wrong Sided Signal Failure, Human Error, Object on or near Track, Adverse Weather, Level Crossings, Wilful Disturbance by Men, others.

Fire usually caused by de-railed. If fire in tunnel, it was the worst case. For safety precaution of fire, passenger trains were designed with high fire resistant rating and easy evacuation.

Equipment failure could be caused by damaged/broken rail (e.g. Side displacement). Wrong Sided Failure such as train detection by human error caused very serious consequence (e.g. Wenzhou Collision). In order to avoid Object on or near Track, any construction near MTR area should inform MTR for evaluation.

Other safety concerns included escalator accident, platform gap accident, platform door accident. Many loss from accident could be reduced by regular incident handling drills

I represented HKSQ to present souvenir to Mr. KW Pang.

Mr. Charles Lung (Vice-chairman of IRSE Hong Kong) presented souvenir to Mr. KW Pang.

The second speaker was Mr. Joseph Ng (Safety & Quality Systems & Knowledge Management Manager, MTR) and his presentation named "Safety Management System for MTR Railway Business".

Mr. Ng introduced MTR railway business included Heavy Rail, Airport Express, Intercity, Light Rail, Bus, Disneyland Resort Line and NP 360 Cable Car.

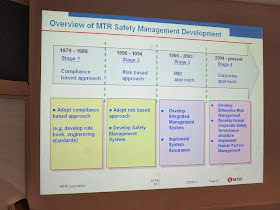

Then Mr. Ng overviewed the MTR safety management development which separated into four stages: 1) Compliance based approach; 2) Risk based approach; 3) IMS approach and 4) Corporate approach.

Moreover, nine key components of MTR safety management system were briefed.

Apart from nine key components, 17 safety tasks which associated with safety objectives and requirements were discussed.

Precursor monitoring was employed to enhance the proactive risk management process which showed in the accident triangle.

MTR Corporate Safety Month is one of safety promotion programmes for MTR staff and contractors. These programmes were very important in safety communication and promotion.

I (Chairman of HKSQ) presented souvenir to Mr. Joseph Ng.

Mr. Charles Lung (Vice-chairman of IRSE Hong Kong) presented souvenir to Mr. Joseph Ng.

Dr. KS Chin (ASQ) was a facilitator to introduce the next speaker.

The third speaker was Dr. Thomas Kwok (Training Manager, Bureau Veritas Certification Hong Kong Limited) and his presentation named "International Railway Industry Standard Certification (IRIS)".

IRIS was a global non-profit program with the intention to secure high quality in the railway industry. It aimed to enhance supra-national competition by enabling railway equipment manufacturers to meet globally recongnized levels of quality for their railway components.

Dr. Kwok said that IRIS was employed for supply chain management in the railway industry.

UNIFE - the Association of the European Rail Industry established IRIS for the rail industries. IRIS group members were shown in following diagram.

Then the certification process flow was introduced. There were 18 types of railway equipment in the first level for certification: 1) Car body, 2) Car body fittings, 3) Guidance (Bogies and running gear), 4) Power System, 5) Propulsion, 6) Auxiliary Systems, 7) Braking System, 8) Interiors, 9) On board vehicle control, 10) Passenger Information Systems, 11) Communication systems, 12) Cabling and Cabinets, 13) Door System, 14) HVAC, 15) Toilet System, 16) Lighting, 17) Coupler and 18) Rolling Stock.

IRIS additional clauses which compared with ISO 9001 were shown below.

4.3 Knowledge management

4.4 Management of multi sites projects

5.5.4 Customer relationship management

6.2.2.1 Human resources - Product design skills

6.3.2 Contingency plan

7.3 Tender management

7.4 Project management

7.5.8 First article inspection (FAI)

7.6 Configuration management

7.10 Reliability/Avaliability/Maintainability/Safety (RAMS) and Life Cycle Costs (LCC)

The following 10 questions called "Knock out questions" which was designated questions as the “Expected Response” did not automatically exclude applicants from receiving a passing score on the requisition. It employed as screening process before IRIS certification.

The last speaker was Dr. Aaron Tong (Managing Director, TQM Consultant Ltd.) and his topic entitled "RoHS - misused and impact to Infrastructure Reliability".

Firstly, Dr. Tong introduced RoHS restricted materials and then he questioned "Shall we implement RoHS as soon as possible?"

He raised an example about 30 year reliability requirement for equipment in CLP Power. Could Lead Free soldering and PCB fulfill the requirement?

Then Dr. Tong mentioned some exemptions of RoH implementation.

Finally, Dr. Tong suggested to use accelerated life test but it was not 100% confidence. It was only a simulation but still better than do nothing.

At the end, Mr. Charles Lung (Vice-chairman of IRSE Hong Kong) gave a closing remarks.

I (Chairman of HKSQ) presented souvenir to Dr. Thomas Kwok.

Mr. Charles Lung (Vice-chairman of IRSE Hong Kong) presented souvenir to Dr. Thomas Kwok.

I (Chairman of HKSQ) presented souvenir to Dr. Aaron Tong.

Mr. Charles Lung (Vice-chairman of IRSE Hong Kong) presented souvenir to Dr. Aaron Tong.

Reference:

Hong Kong Society for Quality (HKSQ) - http://www.hksq.org/index.asp

American Society for Quality (ASQ) - http://asq.org/index.aspx

SEEM, CityU - http://www.cityu.edu.hk/seem/

Institute of Railway Signal Engineers (IRSE) - HK Session - http://www.irse.org.hk/

沒有留言:

發佈留言