The Topic of August seminar entitled “Strategic Inventory Management: Successful Formulas that Market Leaders Are Using Everyday”, which organized by An Executive Study Group under the Chinese University of Hong Kong (CUHK) and the Hong Kong Science and Technology Parks Corp (HKSTPC) on 26 Aug 2011.

Mr. Mark Lee (MBA, CUHK) presented the content including “Why Inventory Management Matters?”, “Aligned Strategy”, “Harmonic Collaboration”, “Sales and Operation Planning” and “Group Discussion”.

In the beginning, Mr. Lee quoted Mr. Gianpaolo Callioni (Director of Supply Chain Strategy and Planning, HP) that inventory-driven costs equaled the PC business's total operating margin.

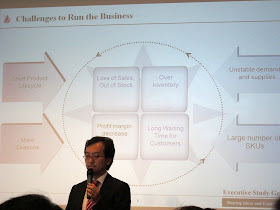

Mr. Lee pointed out some challenges to run the business which related to supply chain such as large number of SKU (Stock-Keeping Unit).

Then he introduced strategic structure of inventory management included Aligned Strategy, Harmonic Collaboration and Sales & Operation Planning (S&OP).

For Aligned Strategy, Mr. Lee quoted the founder of Dell Computer (Mr. Michael Dell) statement on inventory that "How Fast" not "How Much". If using "How Much" based on balance sheet, management would cut down the inventory and affected the service level. When it used "How Fast" concept, inventory would decrease without hurting service level.

There were two product characteristics which separated into "Functional" and "Innovative". Functional product is more long term but margin is low. Innovative product is a short term but margin is high. However, they used different strategy on supply chain.

Mr. Lee used Prof. Marshall L. Fisher's Matching table. It indicated Functional Product matched the Efficient Supply Chain and Innovative Product matched the Responsive Supply Chain. Mr. Lee explained that Efficient Supply Chain was a bus and Responsive Supply Chain was a taxi.

Then Mr. Lee quoted Dr. Harry Lee's statement that reduce cycle time to reduce risk by investment on infrastructure. It indicated that production capacity should be reserved (not 100% utilization).

For Harmonic Collaboration, Mr. Lee suggested "Sticking to a Rhythm" such as Toyota's "Takt Time" and Dell's "Inventory Velocity". Supply chain overall performance should be monitored.

Finally, Mr. Lee briefed the Sales & Operations Plan (S&OP). The following figure showed the process positioning of S&OP.

The 4 step workflow of S&OP was introduced.

S&OP worksheet was mention. There are separated into three parts as "Demand", "Operations" and "Inventory".

S&OP process functions involved "Manufacturing", "Sales", "Marketing", "Sourcing & Procurement" and "Finance". This S&OP process included a formal meeting each month ran by the general manager and covered a planning horizon adequate to plan resources effectively. A concise written S&OP policy is needed.

At the end of the seminar, we had an exercise to find out two of the current biggest challenges and one of the least challenge to Inventory from 8 items.

Reference:

The Centre for Logistics Technologies and Supply Chain Optimization, CUHK: http://www.logitsco.cuhk.edu.hk/

HKSTP - www.hkstp.org

沒有留言:

發佈留言