I would like to summarize all quality related activities I attended in 2008 as follows:

Seminar x16; Training x4, Visit x5 and Conference x6.Seminar:(YYYYMMDD)20080223: Seminar on “RFID: An Emerging Technology for Physical Asset Management (PAM) and Counterfeit Prevention:20080311: Biological Waste Management – Anaerobic Digestion, Composting and Vermicomposting20080313: Medical Devices and Limulus Amebocyte Lysate (LAL) Testing20080429: Jadeite Jade Classification (硬玉翡翠分類)

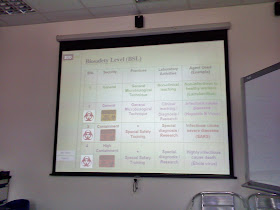

20080704: Considerations for Medical Device Manufacturing – Optimization of materials, applications and sterilization (HKIE)20080729: Exchange @ Science Park for Life Sciences Community20080730: TUV Open Forum on “How to improve the training effectiveness in cost-effective way”20080801: Seminar on ISO 9001:2000 UPGRADE to 2008 Version & Secure your information with ISO 2700120080827: How to win and keep customers coming back (HKSTP)20080911: ISO 9001:2008 Implementation Seminar (HKSQ, HKQAA & HKSTP)20081019: Solutions for Profits (ISCEA)20081106: Technical Seminar on the Aspect of DuPont Risk Based Process Safety Management (PSM)20081122: Solutions for Profits – Part 2 (ISCEA)20081202: Face-reading and Management (HKIE)20081218: Synopsys TCAD Seminar (HKSTP)20081219: Managing the Design of 2008 Beijing Olympics Projects (HKSQ) Training:20080517: Certified Lean Master course organized by International Supply Chain Education Alliance (ISCEA)20081016-17: BCM introduction and implementation training (BSI)20081204-05: APP International Photovoltaic Reliability Workshop20081211: Laboratory Biosafety Training (HKTIC) Visit:20080226: Roberto Saco, ASQ President - Elect, Visiting HK

20080425: Visit to Molecular Biology and Biotechnology Instrument Laboratory in CUHK20080509: Visit two Mainland Medical Devices Manufacturers (HKSQ)20080530: Visit to Kwong Sun Hong Limited (HKSQ)20081107: Visit to Hong Kong Yakult Co. Ltd. (HKSQ) Conference:20080930: Nanotechnology Forum – Solar Energy (HKQAA)20081029-31: ANQ Congress 2008 in Bangkok, Thailand (HKSQ)20081104: The symposium on “Advanced Design & Technology in Healthcare & Laboratory Facilities” (IHEEM(HK))20081129: The Symposium entitled “Innovation.Technology.2008: How Security Technology Protects Our Assets” (iPROA)20081210: InnoAsia 2008 Conference: Enabling Sustainability20081210-12: HKQAA Symposium 2008 - Green Day