The first speaker was Dr. Hong Yang (Xi’an Jizotong University) and his topic was “Quality Control in the Module Production”.

He introduced the IQC of cell testing and sorting as follows:

He introduced the IQC of cell testing and sorting as follows:i) Efficiency under STC

ii) Current measurement at 0.5V under STC

iii) Current measurement at 0.5V under Non-STC

iv) Shunt resistance testing (1500 Ohm.cm2)

v) Reverse current testing

The general standards for solar modules were introduced:

i) Visual inspection

ii) Insulation test

iii) Performance test

iv) Energy production forecast

v) Reliability (30 years)

vi) Micro-crack check-up

vii) Colour sorting

viii) Mechanical conformity

He reviewed the causes of power degradation were:

i) Performance degradation of encapsulation materials

ii) Soldering

iii) Moisture ingress

iv) Inherent device performance degradation

The second speaker: Mr. GuangChun Zhang’s representative (Suntech Power Holdings Co., Ltd.).

Topic: “Common Problems and Their Solutions in the Manufacturing of PV Modules”.

He introduced two phases of degeneration of PV modules output power. They were “early LID” and “modules ageing LID”. He proposed solutions to LID of PV modules for improving Cz-Si quality:

He introduced two phases of degeneration of PV modules output power. They were “early LID” and “modules ageing LID”. He proposed solutions to LID of PV modules for improving Cz-Si quality:i) Improve Cz-Si bar quality with MZC technique

ii) Use N-type P-doped wafer

iii) Change P-type dopant from Boron to Gallium

At last, the representative concluded the following points:

i) During pulling period of Cx-Si, gallium is doped instead of boron without increasing production cost.

ii) Ga-doped cells have good conversion efficiency which is not inferior compared with B-doped Cz-Si.

iii) There is very low or no degeneration of Ga-doped Cz-Si cells and modules.

The third speaker: Mr. Andreas Kuhlen (Director, Global Sales & Marketing – CTS Group).

Topic: “Durability Testing Concepts for the PV Industry”.

He defined the term “Durability” – The ability of a material, component or product to resist wear, decay, etc., under conditions of stress and/or time. For PV, “environment” might include extra-terrestrial or terrestrial outdoor exposure. He also stated the following durability test methodologies:

- ALT (Accelerated Life Tests)

- HALT (Highly Accelerated Life Tests (product robustness))

- ESS (Environmental Stress Screening)

- HASS (Highly Accelerated Stress Screening (infant mortality)

- HAST (Highly Accelerated Stress Test)

- CALT (Calibrated Accelerated Life Tests)

The following figure shows the Weatherability / Environmental Durability factors.

The forth speaker: Dr. John Pern (Senior Scientist II, National Center for Photovoltaics, National Renewable Energy Laboratory).

He presented a topic entitled “Stability Issues of Transparent Conducting Oxides (TCOs) for Thin-Film Photovoltaics”.

Dr. Pern introduced TCO in the different PV applications based on TCO’s performance, cost and thin-film PV fabrication sequence factors. He described the stability of Thin Film PV which had two aspects (Absorber vs. TCO):

For Absorber: CIGS, CdTe, Organic (OPV)

- Sensitivity to moisture at elevate temperature

For TCO: stability concerns as contact electrode or buffer lary or internal reflector

- Sensitivity to moisture and applied voltage at elevated temperature.

The following is an example of different morphological degradations under Damp Heat (DH)

He introduced the IEC Organization for PV via the following figure.

The terms were revealed:

IECEE – International Electrotechnical Commission System for Conformity Testing and Certification of Electrical Equipment

NCB – National Certification Body

CTL – Committee of Testing Laboratories

CBTL – Certification Body Testing Laboratory

ETF 9 PV – Expert Task Forces 9 Photovoltaics

MTL – Manufacturers’ Testing Laboratory

FIC – Factory Inspection Committee

Finally, he pointed out that there was no test or requirements for EVA. More and more new materials would come out; new tests would be required to be developed.

The sixth speaker: Mr. Wei Chen (Vice President, China Quality Certification Centre).

Topic: “System and Procedure of PV Product Certification in China”.

Firstly, He introduced CQC Mark Certification System.

Then he showed us the China certification and accreditation system.

He said 4 China PV testing laboratories signed the testing standard contract with CQC by now and they were:

i) No.18 Research Institute of China Electronics Technology Group Corporation

ii) Shanghai Institute of Space Power-source

iii) Chinese Academy of Sciences Solar Power Generation Systems and Wind Power System, Quality Test Centre

iv) Shenzhen Electronic Product Quality Test Centre

Lastly, he concluded “Thin-film solar cell is the future of solar cell and BIPV is the future of thin-film solar cell.”

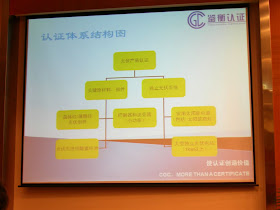

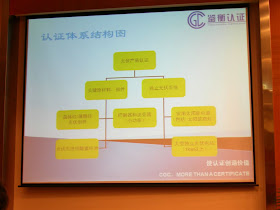

The seventh speaker: Mr. HaiYan Qin’s representative Mr. Wang (China General Certification Center, Shanghai, China).

Topic: “PV Quality Certification Status and Development of China”.

He introduced the certification and accreditation management mechanism in China and then he explained the PV certification structure.

Finally, he shared several research achievements and results such as “Village-Village Electrification” forerunner project in Tibet, “San Jiang Yuan” project in Qinghai province and “New Village Construction” project in China.

The eighth speaker: Mr. Yu Xue (China National PV Products Test Centre).

Topic: “Current Status of National PV Quality Test Center at Wuxi”.

He introduced the process of centre establishment and their testing capability including PV cell and module, energy storage cell, etc.

The ninth speaker: Mr. Gong Daoren (Yangzhou PV & LED Test Centre).

Topic: “State Key Laboratory of PV & LED Testing”.

He said that “China is a large country of PV manufacture, but not a large end-user, more than 95% of the PV products were exported.” Then he affirmed the aims:

i) Become a leading PV testing lab around the world

ii) One testing result according to one standard in our lab recognized around the world

iii) Become CBTL authorized by IEC

He introduced the PV module testing and certification in his centre.

Lastly, he reported the current status of PV Lab that their quality management system has been built according to ISO/IEC 17025 and the requirement of IEC CBTL. All equipment would be arrived the laboratory continually before Jan 2009.

Lastly, he reported the current status of PV Lab that their quality management system has been built according to ISO/IEC 17025 and the requirement of IEC CBTL. All equipment would be arrived the laboratory continually before Jan 2009.

The tenth speaker: Dr. Xu who represented Prof. Xu Honghua (Institute of Electrical Engineering / Chinese Academy of Science).

Topic: “Research on Grid-connected PV System in China”.

He introduced the solar energy and development potential of PV system in China as follows:

i) Installed area and planning of BIPV in China

ii) Research on key technology and equipment such as components used for BIPV and concentration of light technology

iii) Sunpower tracker system

iv) PV grid-connected inverter

v) Ultra scale PV grid-connected inverter

vi) MW scale BIPV grid-connected Plant

He also shared the application of PV system in Beijing 2008 Olympic Games.

The eleventh speaker: Mr. Lai represented Mr. KeQin Wang (Chief Engineer, Shenzhen Electronic Product Quality Testing Center).

Topic: “Partial Discharge Test to Back Sheet in PV Module”.

He introduced the discharge mechanism of partial discharge (PD) as below:

i) PD usually begins within voids, cracks or inclusions within a solid dielectric.

ii) PD within an insulating material are usually initiated within gas-filled voids within the dielectric

iii) The electric field (or the voltage stress) appearing across the void is significantly higher than across an equivalent distance of dielectric.

He also introduced the testing procedure in IEC 61730 (Photovoltaic (PV) module safety qualification).

The twelfth speaker: Mr. ZhengQi Tang (Shanghai Electric Power Green Energy).

Topic: “Research on Megawatt ON-Grid PV Power Generation”.

He introduced the factors which would affect PV Power Generation and its application perspective.

He presented a topic entitled “Stability Issues of Transparent Conducting Oxides (TCOs) for Thin-Film Photovoltaics”.

Dr. Pern introduced TCO in the different PV applications based on TCO’s performance, cost and thin-film PV fabrication sequence factors. He described the stability of Thin Film PV which had two aspects (Absorber vs. TCO):

For Absorber: CIGS, CdTe, Organic (OPV)

- Sensitivity to moisture at elevate temperature

For TCO: stability concerns as contact electrode or buffer lary or internal reflector

- Sensitivity to moisture and applied voltage at elevated temperature.

The following is an example of different morphological degradations under Damp Heat (DH)

- Use ITO to replace Al-doped ZnO

- More DH-stable TCOs – InZnO, InGaZnO (but expensive!)

- Mitigation ZnO with Barrier Coating

- Moisture-blocking polymeric topcover

The fifth speaker: Mr. Liang Ji (Research Engineer, Underwriters Laboratories, Inc.).

Topic: “New Topics of IEC PV Module Standard Development”.

The fifth speaker: Mr. Liang Ji (Research Engineer, Underwriters Laboratories, Inc.).

Topic: “New Topics of IEC PV Module Standard Development”.

He introduced the IEC Organization for PV via the following figure.

The terms were revealed:

IECEE – International Electrotechnical Commission System for Conformity Testing and Certification of Electrical Equipment

NCB – National Certification Body

CTL – Committee of Testing Laboratories

CBTL – Certification Body Testing Laboratory

ETF 9 PV – Expert Task Forces 9 Photovoltaics

MTL – Manufacturers’ Testing Laboratory

FIC – Factory Inspection Committee

Finally, he pointed out that there was no test or requirements for EVA. More and more new materials would come out; new tests would be required to be developed.

The sixth speaker: Mr. Wei Chen (Vice President, China Quality Certification Centre).

Topic: “System and Procedure of PV Product Certification in China”.

Firstly, He introduced CQC Mark Certification System.

Then he showed us the China certification and accreditation system.

He said 4 China PV testing laboratories signed the testing standard contract with CQC by now and they were:

i) No.18 Research Institute of China Electronics Technology Group Corporation

ii) Shanghai Institute of Space Power-source

iii) Chinese Academy of Sciences Solar Power Generation Systems and Wind Power System, Quality Test Centre

iv) Shenzhen Electronic Product Quality Test Centre

Lastly, he concluded “Thin-film solar cell is the future of solar cell and BIPV is the future of thin-film solar cell.”

The seventh speaker: Mr. HaiYan Qin’s representative Mr. Wang (China General Certification Center, Shanghai, China).

Topic: “PV Quality Certification Status and Development of China”.

He introduced the certification and accreditation management mechanism in China and then he explained the PV certification structure.

Finally, he shared several research achievements and results such as “Village-Village Electrification” forerunner project in Tibet, “San Jiang Yuan” project in Qinghai province and “New Village Construction” project in China.

The eighth speaker: Mr. Yu Xue (China National PV Products Test Centre).

Topic: “Current Status of National PV Quality Test Center at Wuxi”.

He introduced the process of centre establishment and their testing capability including PV cell and module, energy storage cell, etc.

The ninth speaker: Mr. Gong Daoren (Yangzhou PV & LED Test Centre).

Topic: “State Key Laboratory of PV & LED Testing”.

He said that “China is a large country of PV manufacture, but not a large end-user, more than 95% of the PV products were exported.” Then he affirmed the aims:

i) Become a leading PV testing lab around the world

ii) One testing result according to one standard in our lab recognized around the world

iii) Become CBTL authorized by IEC

He introduced the PV module testing and certification in his centre.

Lastly, he reported the current status of PV Lab that their quality management system has been built according to ISO/IEC 17025 and the requirement of IEC CBTL. All equipment would be arrived the laboratory continually before Jan 2009.

Lastly, he reported the current status of PV Lab that their quality management system has been built according to ISO/IEC 17025 and the requirement of IEC CBTL. All equipment would be arrived the laboratory continually before Jan 2009.The tenth speaker: Dr. Xu who represented Prof. Xu Honghua (Institute of Electrical Engineering / Chinese Academy of Science).

Topic: “Research on Grid-connected PV System in China”.

He introduced the solar energy and development potential of PV system in China as follows:

i) Installed area and planning of BIPV in China

ii) Research on key technology and equipment such as components used for BIPV and concentration of light technology

iii) Sunpower tracker system

iv) PV grid-connected inverter

v) Ultra scale PV grid-connected inverter

vi) MW scale BIPV grid-connected Plant

He also shared the application of PV system in Beijing 2008 Olympic Games.

The eleventh speaker: Mr. Lai represented Mr. KeQin Wang (Chief Engineer, Shenzhen Electronic Product Quality Testing Center).

Topic: “Partial Discharge Test to Back Sheet in PV Module”.

He introduced the discharge mechanism of partial discharge (PD) as below:

i) PD usually begins within voids, cracks or inclusions within a solid dielectric.

ii) PD within an insulating material are usually initiated within gas-filled voids within the dielectric

iii) The electric field (or the voltage stress) appearing across the void is significantly higher than across an equivalent distance of dielectric.

He also introduced the testing procedure in IEC 61730 (Photovoltaic (PV) module safety qualification).

The twelfth speaker: Mr. ZhengQi Tang (Shanghai Electric Power Green Energy).

Topic: “Research on Megawatt ON-Grid PV Power Generation”.

He introduced the factors which would affect PV Power Generation and its application perspective.

The thirteenth speaker: Ms. Cecile Warner (National Renewable Energy Laboratory, DOE).

Topic: “BIPV and the Solar Decathlon” and “BIPV Market Growth and the Role of Reliability”.

She introduced the objectives of Solar Decathlon and the rules for participants. The competition is to design, build and operate the most attractive and energy-efficient solar-powered house.

The second topics was the BIPV Market. She introduced Professor Kosuke Kurokawa who was the first scholar to develop the R&D proposal regarding the grid-connected concept of residential PV systems in 1977. BIPV Reliability and Maintainability were concerned.

Lastly, she concluded:

i) More than 10GW or BIPV will be installed in 5 years

ii) BIPV market growth is both good news and a call to action.

iii) NREL invites industry and laboratory colleagues around the world to join in the assessment.

Topic: “BIPV and the Solar Decathlon” and “BIPV Market Growth and the Role of Reliability”.

She introduced the objectives of Solar Decathlon and the rules for participants. The competition is to design, build and operate the most attractive and energy-efficient solar-powered house.

The second topics was the BIPV Market. She introduced Professor Kosuke Kurokawa who was the first scholar to develop the R&D proposal regarding the grid-connected concept of residential PV systems in 1977. BIPV Reliability and Maintainability were concerned.

Lastly, she concluded:

i) More than 10GW or BIPV will be installed in 5 years

ii) BIPV market growth is both good news and a call to action.

iii) NREL invites industry and laboratory colleagues around the world to join in the assessment.

The fourteenth speaker: Mr. Wu Guoliang (VP, Trony Solar).

Topic: “BIPV Module Manufacturing and Quality Control”.

He introduced different BIPV modules including dot-transparent a-Si solar PV insulated-laminated glass, shutter a-Si solar PV laminated glass and shutter a-Si solar PV insulated glass, etc.

He also briefed us several success cases.

The last speaker of day two was Mr. Wei Chen (Solarfun Power Holding Co., Ltd.) and his topic was “Performance Reliability Evaluation of BIPV Modules and Systems”.

He introduced the process of crystalline silicon BIPV Module Production. Moreover, he summarized several problems, including:

i) Glass Self-breaking

ii) UV-Browning

iii) Temperature (Over-heating of the BIPV module in the summer)

iv) Un-identical radiation for modules in the PV system

v) Accumulation of dust

Topic: “BIPV Module Manufacturing and Quality Control”.

He introduced different BIPV modules including dot-transparent a-Si solar PV insulated-laminated glass, shutter a-Si solar PV laminated glass and shutter a-Si solar PV insulated glass, etc.

He also briefed us several success cases.

The last speaker of day two was Mr. Wei Chen (Solarfun Power Holding Co., Ltd.) and his topic was “Performance Reliability Evaluation of BIPV Modules and Systems”.

He introduced the process of crystalline silicon BIPV Module Production. Moreover, he summarized several problems, including:

i) Glass Self-breaking

ii) UV-Browning

iii) Temperature (Over-heating of the BIPV module in the summer)

iv) Un-identical radiation for modules in the PV system

v) Accumulation of dust

Who knows where to download XRumer 5.0 Palladium?

回覆刪除Help, please. All recommend this program to effectively advertise on the Internet, this is the best program!