The

webinar named “How Products Reliability and Systems Safety help Local Industry

to address market needs and promote business opportunities” was organized by

Centre for Advan es in Reliability and Safety (CAiRS) and supported by HKSTP on

26th Nov 2020. It aimed to

share industrial and research experiences on products reliability and systems

safety and how the industry needs could be addressed and business opportunities

could be promoted.

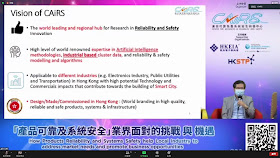

Prof.

Winco Yung (Centre Director, CAiRS) was the first speaker and his topic

entitled “Introduction of Reliability and Safety Research in CAiRS”. Firstly, Prof. Yung mentioned the vision of

CAiRS that aimed to be world leading and regional hub for research in

reliability and safety innovation.

And

then he introduced CAiRS approach in which focused on AI based methods for

system health assessment so as to ensure reliability and safety. It aimed to develop

a real-time and predictive solution for system safety.

After

that Prof. Yung introduced five key research programs for achieving their

objectives below.

l

Identification and acquisition of useful data relating

to reliability and safety.

l

Development of different AI technologies in

bridging the above knowledge gaps and formation industry big data

l

Integration of Data-driven Model and Physics of

Failures approaches on data set in various industry sectors

l

Development of algorithm for Predictive Failure of

critical components and systems

l Formulation of practical modelling on product’s life prediction and process quality forecast

Finally,

Prof. Wu stated their testing laboratory capabilities included AI

supercomputing, Temperature & Environment Testing, Failure Analysis

Equipment and Life Cycle Assessment Equipment. Moreover, he also introduced their

team member in different departments in PolyU with different supporting organizations

such as HKEIA, HKEIC, ASM, Compass, nVidia, HAECO, CLP, GP, Defond, … etc.

Lastly,

Prof. Wu emphasized several benefits to collaborate between Industry and CAiRS

such as failure prevention and cost saving.

Until now, there were five application sectors in the program and they

were Transportation, Public Utility, Products, Parts & Components, and Data

Integrity & Software Trustworth.

Dr.

Brian Li (Executive VP, Gold Peak Industries (Holdings) Limited) was the second

speaker and his presentation named “Marketing Needs and Challenges of Products

Reliability and Systems Safety”. In the

beginning, Dr. Li briefed the background of Gold Peak Group.

Then

Dr. Li mentioned the product quality and reliability that was the livelihood of

a manufacturer. He said that the integral

cost of supplying products to customers included customer service costs and

warranty costs, which could be higher than the manufacturer’s Free On Board

(FOB) cost in terms of brand. Therefore,

high quality and high reliability is a most important qualification to establish

the brand. After that he briefed their

group’s batteries was working with CAiRS on new approaches for assessing

product reliability using Big Data analysis and AI techniques.

Finally,

Dr. Li briefed their GP batteries service and requirements. He expected the best quality and reliability were

achieved before new product launch through new technology and research employed

from the program with CAiRS.

The

last speaker was Dr. Steven Boles (Associate Professor, PolyU) and his

presentation title was “Reliability and Safety Research Methodology with

Industrial Applications”. Firstly, he briefed the demand trend for energy. Electricity increasing daily was observed that

Natural Gas and Renewables were growing.

Then

Dr. Boles said we needed for energy storage using electrochemical energy

storage device. It was observed that

Lithium-ion Battery (LIB) was growing in recently years.

After

that Dr. Boles briefed the principles of LIBs and said more energy stored, the higher

risk was. Therefore, safety and reliability

of LIBs were concerned especially travelling in fight (e.g. spare lithium

batteries never go in a checked bag).

Finally,

Dr. Boles briefed some cases about “Physics of Failure” in LIB such as Li-metal

plating, Overcharging, Manufacturing issues, thermal runaway, etc. Therefore, he suggested to add sensing in

batteries like “canary” device so as to improve safety, reliability and health

in the future.

Reference:

沒有留言:

發佈留言