The trainer was Mr. Mark Lee and his talk content included “Current Situation”, “The 9 Ways” and “Group Discussion”.

In the beginning, Mr. Lee introduced the current situation using Compaq case and “The World is Flat”. Moreover, the diminishing of the middle price occurred.

The he briefed the challenges to run the business included “Short Product Lifecycle”, “More Seasons”, “Unstable demands and supplies” and “Large number of Stock Keeping Units (SKUs)”.

After that Mr. Lee mentioned the 9 ways to increasing speed as follow.

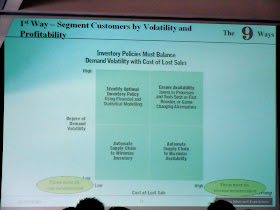

1st Way: Segment Customers by Volatility and Profitability.

Using the following chart to optimize the limited resources allocations and he suggested to determine an overall inventory policy such as balance of the demand volatility and cost of a lost sale.

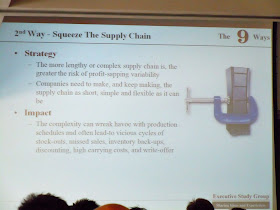

2nd Way: Squeeze the Supply Chain

Companies need to make and keep making the supply chain as short, simple and flexible as it can be.

3rd Way: Rethink and Examine Existing Inventory

Rethink whether continue to use the same inventory management methods for new markets and new products; and spend efforts to find out the real demand.

Case study of Toyota: explaining the Trade-Off of Cost and Lost-of-Sales in USA.

It is the rule of 80:20.

5th Way: Tailor Different Service Levels to Different Customer SegmentsCompanies can focus their capabilities, minimize overall costs, and increase the flexibility of their supply chains by varying service levels based on customer value. It is the same approach that Good Quality is not equal to the Highest Quality.

6th Way – Focus on Core Competences; Outsource for the RestMany companies try to do too much. It needs to rethink the company’s business model such as non-strategic tasks could be offloaded.

8th Way: Apply the Right KPI and Reward Schemes

Details could be found in previous seminar at http://qualityalchemist.blogspot.com/2010/07/five-pitfalls-of-key-performance.html

9th Way: Foster “Favored” Strategic Suppliers

The strategy is to align partners’ interests such as share risks, costs and rewards equitable.

Finally, Mr. Lee concluded that all ways aimed to reduce the Variability.

In Group Discussion, it was to rank the 9 ways using 3√and 3X.

5th Way: Tailor Different Service Levels to Different Customer SegmentsCompanies can focus their capabilities, minimize overall costs, and increase the flexibility of their supply chains by varying service levels based on customer value. It is the same approach that Good Quality is not equal to the Highest Quality.

6th Way – Focus on Core Competences; Outsource for the RestMany companies try to do too much. It needs to rethink the company’s business model such as non-strategic tasks could be offloaded.

The example shows the mis-matching of sales quantity and stock refill.

8th Way: Apply the Right KPI and Reward Schemes

Details could be found in previous seminar at http://qualityalchemist.blogspot.com/2010/07/five-pitfalls-of-key-performance.html

9th Way: Foster “Favored” Strategic Suppliers

The strategy is to align partners’ interests such as share risks, costs and rewards equitable.

Finally, Mr. Lee concluded that all ways aimed to reduce the Variability.

In Group Discussion, it was to rank the 9 ways using 3√and 3X.

After the seminar, I reviewed what I learnt in Quality. I believed that the outcome to implement Lean and 6 Sigma in strategy level could also obtain the same result.

http://qualityalchemist.blogspot.com/2008/05/certified-lean-master-study-sharing.html

For more information:

The Centre for Logistics Technologies and Supply Chain Optimization, CUHK: http://www.logitsco.cuhk.edu.hk/

http://qualityalchemist.blogspot.com/2008/05/certified-lean-master-study-sharing.html

For more information:

The Centre for Logistics Technologies and Supply Chain Optimization, CUHK: http://www.logitsco.cuhk.edu.hk/

沒有留言:

發佈留言