I would like to summarize all quality related activities I attended in 2009 as follows:

Seminar x23; Training x3, Visit x3 and Conference x4.

Seminar:(YYYYMMDD)

20090105: Upgrade your ISO 9001:2000 to ISO 9001:2008 & Get Equipped to meet the Challenges of the Economic Downturn (HKSQ)

20090110: Quality in Outsourcing (HKSQ)

20090220: PCB and Packaging Technologies (Physical Society of Hong Kong and HKPC)

20090220: Fail and Fix to Predict and Prevent – A Paradigm Shift in Engineering Asset Management (CityU HK)

20090226: A Critical Rethink of Supplier Quality Assurance Management of Hardware Manufacturing (HKSQ & ISMHK)

20090402: Development of China DTV – Digital Terrestrial Multimedia Broadcasting (HKSTP)

20090403: A New Perspective on Electronic Product Reliability (CityU HK)

20090414: Solar Photovoltaic Energy (PV) – From Technology to Business Opportunities (HKEIA)

20090423: Maximise SMEs’ Business Potential through Intellectual Capital Management & Knowledge Management (EngD Society)

20090428: Realizing Value from IT Investment (HKSTP)

20090508: Latest EU Standard and LED Technology in Lighting Industry (HKSTP & ITS)

20090513: Building a Sustainable Future for Hong Kong through Technology Development (HKIE)

20090710: Sharing Entrepreneur Experience in Healthcare Products and Medical Devices & Diversify into Medical Manufacturing Business (HKSQ – AGM)

20090807: IPO Process in Hong Kong & Role of Financial Adviser (HKSTP)

20090822: Innovation – From Art to Science (HKSTP)

20090827: Embracing the Challenges of Emerging Information Security Threats (HKQAA & HKSQ)

20090910: Biomedical MEMS (CityU HK)

20090911: How to Interpret Performance in Proficiency Test / External Quality Assessment Scheme (HKAS)

20091014: Chemosensors & Chemosensing Technology Development (CityU HK)

20091016: Effectively Managing a Pharmaceutical GMP Laboratory (SGS)

20091112: Quality Assurance in Food Industry (CityU & HKPC)20091124: ISO 14971 Risk Management for Medical Device Manufacturer (HKSQ & SGS)

20091127: Hong Kong Council for Testing and Certification (HKCTC) Consultation Forum (HKAS & HKCTC)

Training:

20090313: Effective Performance Appraisal (Hi-Po Management Consultant Company Limited)

20090527: Business Sustainability: Key to Long-term Success (HKQAA)

20091214-16: GMP Compliance Training: Implementing Regulatory and GMP Requirements into the Operations of Pharmaceutical Companies (SGS)

Visit:

20090227: Secrets of KMB’s Exemplary Bus Service and Fleet Management (HKSQ)

20090423: Technical Visit to Hong Kong Disneyland (IIE-HK)

20090704: Visit to The Hong Kong Jockey Club’s Racing Laboratory (HKTIC)

Conference:

20090512: HKQAA Carbon Conference “Carbon Emission Reduction – The Right Thing to Do” (HKQAA)

20090916-18: ANQ Congress 2009 in Tokyo, Japan (HKSQ)

20091124-25: An Evolution of CSR Era – After Economic Crisis (HKQAA Symposium 2009)

20091201-02: InnoAsia 2009 Conference (HKSTP)

2009年12月31日星期四

2009年12月29日星期二

Certificate Course on “Quality Management for Laboratory” supported by HKSQ

I would like to introduce the coming training course entitled “Quality Management for Laboratory” organized by Hong Kong Society for Quality (HKSQ) and Dept. of Biology and Chemistry, The City University of Hong Kong (BCH, CityU HK).

In 2002, I recognized that students, studying chemistry and/or biology, did not understand the industrial requirements on laboratory operations. Thus, I delivered two special training seminars on the related context for BCH students in CityU HK. After that, the relevant body of knowledge was proposed by Dr. KS Chin and I (representatives of HKSQ), as well as, Dr. Richard Cheung and Dr. Michael Lam (representatives of BCH, CityU HK) to the Head of BCH Department and it was supported positively. Now, it is the fifth intake and the end date will be on 21st January 2010. (More details: http://www.hksq.org/nevents.htm )

The leaflet of the special seminar 2002 is shown.

The course not only includes lectures and laboratory works, but also laboratories visits. Therefore, students would gain some experience in the commercial laboratory environment. Some photos are shown as follows:

Lectures:

Dr. Lam’s Lecture in 2005

In 2002, I recognized that students, studying chemistry and/or biology, did not understand the industrial requirements on laboratory operations. Thus, I delivered two special training seminars on the related context for BCH students in CityU HK. After that, the relevant body of knowledge was proposed by Dr. KS Chin and I (representatives of HKSQ), as well as, Dr. Richard Cheung and Dr. Michael Lam (representatives of BCH, CityU HK) to the Head of BCH Department and it was supported positively. Now, it is the fifth intake and the end date will be on 21st January 2010. (More details: http://www.hksq.org/nevents.htm )

The leaflet of the special seminar 2002 is shown.

The course not only includes lectures and laboratory works, but also laboratories visits. Therefore, students would gain some experience in the commercial laboratory environment. Some photos are shown as follows:

Lectures:

Dr. Lam’s Lecture in 2005

My Lecture in 2006

Examination:

Photo taken in 2005

Laboratory Visit:

2005 HKPC

2006 HKSTP

2007 HAECO

2008 HKSTP

Quality Management for Laboratory is a certificate course to fill the gap between the industry requirements and tertiary education. It is one of the deliverables after I studied the contribution of quality society in 2008 and developed the Quality Professional Development (QProfD) Gap Analysis Model which aimed to analyze the process of developing the body of knowledge for quality professionals between the talents needed by industry and talents trained by Educational Institution.

(My presentation recorded in http://qualityalchemist.blogspot.com/2008/10/anq-2008-part-2.html )

In addition, by considering the industrial needs, a bachelor course entitled “Bachelor of Engineering (Honours) in Total Quality Engineering (BETQE)” was developed by Department of Manufacturing Engineering and Engineering Management (MEEM), CityU HK in 2009. (For Details: http://www.cityu.edu.hk/meem/prg-betqe.htm)

The Bachelor degree was expected to fill the gap of “Differences between Industry’s expectations of competent Quality Professionals, and Educational Institution’s perceptions of those expectations”.

Reference:

Lai, Lotto K.H., Chin, K.S. & Tsang, A.H.C. (2008) “A Conceptual Model on Development of Quality Professionals” Proceedings CD-ROM of The sixth ANQ Congress, paper C1-05.

Examination:

Photo taken in 2005

Laboratory Visit:

2005 HKPC

2006 HKSTP

2007 HAECO

2008 HKSTP

Quality Management for Laboratory is a certificate course to fill the gap between the industry requirements and tertiary education. It is one of the deliverables after I studied the contribution of quality society in 2008 and developed the Quality Professional Development (QProfD) Gap Analysis Model which aimed to analyze the process of developing the body of knowledge for quality professionals between the talents needed by industry and talents trained by Educational Institution.

(My presentation recorded in http://qualityalchemist.blogspot.com/2008/10/anq-2008-part-2.html )

In addition, by considering the industrial needs, a bachelor course entitled “Bachelor of Engineering (Honours) in Total Quality Engineering (BETQE)” was developed by Department of Manufacturing Engineering and Engineering Management (MEEM), CityU HK in 2009. (For Details: http://www.cityu.edu.hk/meem/prg-betqe.htm)

The Bachelor degree was expected to fill the gap of “Differences between Industry’s expectations of competent Quality Professionals, and Educational Institution’s perceptions of those expectations”.

Reference:

Lai, Lotto K.H., Chin, K.S. & Tsang, A.H.C. (2008) “A Conceptual Model on Development of Quality Professionals” Proceedings CD-ROM of The sixth ANQ Congress, paper C1-05.

2009年12月17日星期四

GMP Compliance Training (Day 3)

Day 3 (16 Dec 2009)

Dr. Claren Woo (Section Manager, Life Sciences Service) presented “Environmental Monitoring of Facilities” and “Quality Control for Analytical Test”. After that Ms. Cherry Lau (Sr. Technical Executive) gave the last two sessions entitled “GMP for Warehouses and Distribution Centres” and “Microbiology Laboratory”.

Dr. Woo introduced different types of cleanroom classes as follows:

International: ISO 14644 & WHO

National: EU GGMP, EC PIC/S, TGA, FDA & ISPE

The following method characteristics were considered for test method validation.

- Specificity (Selectivity)

- Linearity

- Range

- Accuracy and Precision

- Detection Limit and Quantitation Limit

- Robustness and Stress Test

Specificity and Robustness were selected to further describe below.

Specificity is the ability to assess unequivocally the analyte in the presence of components which may be expected to be present. Typically these might include impurities, degradants, matrix, etc.

The robustness of an analytical procedure is a measure of its capacity to remain unaffected by small, but deliberate variations in method parameters and provides an indication of its reliability during normal usage.

The follows are some international guidelines for stability studies:

ICH: Q1A(R2) “Stability Testing of New Drug Substance and Products”

ASEAN: Guideline “Stability Studies of Drug Products”

US FDA: Guidance for Industry “Stability Testing of Drug Substances and Drug Products: June 1998”

WHO: TRS 863, Annex 5: “Guidelines for Stability Testing of Pharmaceutical Products Containing Well Established Drug Substances in Conventional Dosage Forms”

EMEA: Note for Guidance on Stability Testing of Existing Active Substance and Related Finished Products (Draft), Feb 2002.

In the last two sessions, Cherry introduced GDP for pharmaceutical products in which cold chain management was included.

It concerns if the required temperature and relative humidity is maintained inside the delivery case of pharmaceutical products. (e.g. using cold chain for thermolabile products)

GDP concerns about:

i) microbial contamination source,

ii) temperature & humidity requirements, and

iii) counterfeit products detection and handling.

Lastly, she introduced different functions in microbiology laboratory.

For microbial identification, morphology is the fundamental information.

Api system is a tool commonly used for microbial identification.

Water testing is also important. Some test methods were discussed below:

- Total Viable Count (TVC) using Membrane Filtration / Spread Plate

- Endotoxin using LAL test (Limulus amebocyte lysate) / KQCL (Kinetic Chromogenic LAL Assay)

After the 3-day course, I learnt a lot of basic knowledge of GMP for pharmaceutical manufacturing. The course was found very intensive and informative.

Dr. Claren Woo (Section Manager, Life Sciences Service) presented “Environmental Monitoring of Facilities” and “Quality Control for Analytical Test”. After that Ms. Cherry Lau (Sr. Technical Executive) gave the last two sessions entitled “GMP for Warehouses and Distribution Centres” and “Microbiology Laboratory”.

Dr. Woo introduced different types of cleanroom classes as follows:

International: ISO 14644 & WHO

National: EU GGMP, EC PIC/S, TGA, FDA & ISPE

The following method characteristics were considered for test method validation.

- Specificity (Selectivity)

- Linearity

- Range

- Accuracy and Precision

- Detection Limit and Quantitation Limit

- Robustness and Stress Test

Specificity and Robustness were selected to further describe below.

Specificity is the ability to assess unequivocally the analyte in the presence of components which may be expected to be present. Typically these might include impurities, degradants, matrix, etc.

The robustness of an analytical procedure is a measure of its capacity to remain unaffected by small, but deliberate variations in method parameters and provides an indication of its reliability during normal usage.

The follows are some international guidelines for stability studies:

ICH: Q1A(R2) “Stability Testing of New Drug Substance and Products”

ASEAN: Guideline “Stability Studies of Drug Products”

US FDA: Guidance for Industry “Stability Testing of Drug Substances and Drug Products: June 1998”

WHO: TRS 863, Annex 5: “Guidelines for Stability Testing of Pharmaceutical Products Containing Well Established Drug Substances in Conventional Dosage Forms”

EMEA: Note for Guidance on Stability Testing of Existing Active Substance and Related Finished Products (Draft), Feb 2002.

In the last two sessions, Cherry introduced GDP for pharmaceutical products in which cold chain management was included.

It concerns if the required temperature and relative humidity is maintained inside the delivery case of pharmaceutical products. (e.g. using cold chain for thermolabile products)

GDP concerns about:

i) microbial contamination source,

ii) temperature & humidity requirements, and

iii) counterfeit products detection and handling.

Lastly, she introduced different functions in microbiology laboratory.

For microbial identification, morphology is the fundamental information.

Api system is a tool commonly used for microbial identification.

Water testing is also important. Some test methods were discussed below:

- Total Viable Count (TVC) using Membrane Filtration / Spread Plate

- Endotoxin using LAL test (Limulus amebocyte lysate) / KQCL (Kinetic Chromogenic LAL Assay)

After the 3-day course, I learnt a lot of basic knowledge of GMP for pharmaceutical manufacturing. The course was found very intensive and informative.

2009年12月16日星期三

GMP Compliance Training (Day 2)

Day 2 (15 Dec 2009)

Ms. Cherry Lau (Sr. Technical Executive) presented another four sessions on day 2, including “Materials Management; Documentation & Record Keeping”, “Production and Quality Control” and “GMP for Active Pharmaceutical Ingredients (APIs)”

The usage of Water for pharmaceutical was also introduced. Different types of water used in pharmaceutical processes were showed as follows:

i) Purified Water

ii) Water for Injections (WFI)

iii) Softened Water (removal of calcium and magnesium)

iv) Water for Final Rinse

v) Pure, or Clean Steam

vi) Water for Cooling Autoclaves

There were five types of contaminant groups in water.

i) Inorganic compounds (e.g. chloramines, magnesium carbonate, etc.)

ii) Organic compounds (e.g. detergent residues, solvents, etc.)

iii) Solids (e.g. clay, soils)

iv) Gases (e.g. N2, CO2, O2, etc.)

v) Micro-organisms which can grow in nutrient-depleted conditions

The most troublesome contaminant of water is Biofilm which is formed by micro-organisms. Biofilm formation comes from the follow steps:

i) Free swimming aquatic bacteria use polymucosaccharides to colonise surfaces.

ii) Complex communities evolve which shed micro-colonies and bacteria.

One of water testing methods is membrane filtration which could isolate microbial contaminant for identification.

After that the specific requirements for following types of materials were reviewed:

- Starting materials

- Packaging materials

- Intermediate and bulk products

- Finished products

- Rejected and recovered materials

- Recalled products

- Returned goods

- Reagents and culture media

- Reference standards

- Waste materials

- Miscellaneous materials

Documentation is an essential part of QA and related to all aspects of GMP which ensures that specifications for all materials and methods of manufacture and control are available; assures all personnel know what to do and when to do it; and ensure that Authorized Persons will has all information necessary for release; as well as, all documents available for audit trail.

There were different types of documentation below:

- Labels, specifications and master formulae

- Batch processing and batch packaging records

- Standard operating procedures

- Stock control and distribution records

- Water quality manual, etc.

Then trainer briefed the FDA inspection and showed the most common GMP deficiencies by systems as follows:

- Quality (46%)

- Laboratory (19%)

- Facilities of equipment (17%)

- Production (11%)

- Material (6%)

- Packaging & labeling (1%)

At the end, the GMP guidelines for manufacturing of Active Pharmaceutical Ingredients (APIs) were discussed. It covered “General considerations”, “Personnel”, “Premises”, “Equipment”, “Sanitation”, “Documentation”, “Retention of records and sample” and “Production”.

GMP of APIs is governed by Technical Requirements of International Conference on Harmonization (ICH) for registration of Pharmaceuticals for Human Use (ICH Q7). It was established in 1999 and aims to increase international harmonization of technical requirements to ensure that safe, effective, high quality medicines are developed and registered in the most efficient and cost-effective manner.

Ms. Cherry Lau (Sr. Technical Executive) presented another four sessions on day 2, including “Materials Management; Documentation & Record Keeping”, “Production and Quality Control” and “GMP for Active Pharmaceutical Ingredients (APIs)”

The usage of Water for pharmaceutical was also introduced. Different types of water used in pharmaceutical processes were showed as follows:

i) Purified Water

ii) Water for Injections (WFI)

iii) Softened Water (removal of calcium and magnesium)

iv) Water for Final Rinse

v) Pure, or Clean Steam

vi) Water for Cooling Autoclaves

There were five types of contaminant groups in water.

i) Inorganic compounds (e.g. chloramines, magnesium carbonate, etc.)

ii) Organic compounds (e.g. detergent residues, solvents, etc.)

iii) Solids (e.g. clay, soils)

iv) Gases (e.g. N2, CO2, O2, etc.)

v) Micro-organisms which can grow in nutrient-depleted conditions

The most troublesome contaminant of water is Biofilm which is formed by micro-organisms. Biofilm formation comes from the follow steps:

i) Free swimming aquatic bacteria use polymucosaccharides to colonise surfaces.

ii) Complex communities evolve which shed micro-colonies and bacteria.

One of water testing methods is membrane filtration which could isolate microbial contaminant for identification.

After that the specific requirements for following types of materials were reviewed:

- Starting materials

- Packaging materials

- Intermediate and bulk products

- Finished products

- Rejected and recovered materials

- Recalled products

- Returned goods

- Reagents and culture media

- Reference standards

- Waste materials

- Miscellaneous materials

Documentation is an essential part of QA and related to all aspects of GMP which ensures that specifications for all materials and methods of manufacture and control are available; assures all personnel know what to do and when to do it; and ensure that Authorized Persons will has all information necessary for release; as well as, all documents available for audit trail.

There were different types of documentation below:

- Labels, specifications and master formulae

- Batch processing and batch packaging records

- Standard operating procedures

- Stock control and distribution records

- Water quality manual, etc.

Then trainer briefed the FDA inspection and showed the most common GMP deficiencies by systems as follows:

- Quality (46%)

- Laboratory (19%)

- Facilities of equipment (17%)

- Production (11%)

- Material (6%)

- Packaging & labeling (1%)

At the end, the GMP guidelines for manufacturing of Active Pharmaceutical Ingredients (APIs) were discussed. It covered “General considerations”, “Personnel”, “Premises”, “Equipment”, “Sanitation”, “Documentation”, “Retention of records and sample” and “Production”.

GMP of APIs is governed by Technical Requirements of International Conference on Harmonization (ICH) for registration of Pharmaceuticals for Human Use (ICH Q7). It was established in 1999 and aims to increase international harmonization of technical requirements to ensure that safe, effective, high quality medicines are developed and registered in the most efficient and cost-effective manner.

2009年12月14日星期一

GMP Compliance Training (Day 1)

I attended a GMP training course entitled “GMP Compliance Training: Implementing Regulatory and GMP Requirements into the Operations of Pharmaceutical Companies” which was organized by SGS from 14th to 16th December 2009. The course was designed for individuals from all levels within pharmaceutical manufacturing organizations focusing on QA, QC, Production and Management. I would like to summarize some contents for sharing.

Day 1 (14 Dec 2009)

Ms. Cherry Lau (Sr. Technical Executive) was the trainer who presented the four sessions in day 1, including “General principle of GMP”, “Personnel; training; sanitization & cleaning”, “Premises & equipment; qualification & validation” and “Complaints; deviations; returns; recalls; contract production & testing; self inspections; quality audit”.

The following figure showed the GxP in different pharmaceutical legislative cycle. It is a very useful to overview the whole picture of GLP/GCP/GMP.

GMP applies to “Critical” processes, which means any process that directly or indirectly may have a negative impact on safety, quality or efficacy of the product are concerned. It ensures quality, safety and efficacy of drugs delivered to patients.

The GMP manufacturing site diagram

Quality Relationships:

Quality Management > Quality Assurance > GMP > Quality Control and Manufacturing

In ISO 9000:2005, the definition of audit and inspection are given in following:

Audit: systematic, independent and documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which audit criteria are fulfilled.

Inspection: conformity evaluation by observation and judgment accompanied as appropriate by measurement, testing or gauging.

It has some different interpretation in GMP below.

Inspections are carried out by government agencies (also called the Competent Authorities).

Audits are preformed by drug companies (also called the Marketing Authorization Holder), including:

- Internal self-inspections

- External audits of suppliers and contractors

Personnel requirements were also introduced. Individuals must receive training in GMP:

- initial training

- continuing training, including hygiene standards

Heads of Production and Quality Control should be independent of each other but they may share some responsibilities depending on the national regulations such as authorization of written procedures (SOPs) and other documents, environmental monitoring and control, process validation and calibration, training, etc.

For Sanitation and Hygiene requirements, all aspects of manufacturing should be considered including personnel, premises, equipment, apparatus, production materials and container, and all potential sources of cross-contamination.

The following factors should be considered to prevent cross-contamination.

- Segregated areas for production

- Ventilation systems and airlocks

- Clothing

- Closed processing systems

- Cleaning and decontamination

The manufacturing environment is critical for product quality, such as light, temperature, humidity, air movement, microbial contamination, particulate contamination, etc.

The different classifications of cleanroom were shown.

The validation requirements of cGMP were shown in the following sequence.

i) User Requirement Specification (URS)

ii) Impact assessment

iii) Design Review (DR) or Design Qualification (DQ)

iv) Commissioning / Qualification

v) Installation Qualification (IQ)

vi) Operational Qualification (OQ)

vii) Performance Qualification (PQ)

viii) Cleaning Validation (CV)

ix) Process Validation (PV)

One of the most important documents for GMP inspection is Validation Master Plan (VMP) which should contain at least:

i) Validation policy

ii) Organization structure

iii) Summary of facilities, systems, equipment, processes to be validated

iv) Documentation format for protocols and reports

v) Planning and scheduling

vi) Change control

vii) Training requirement

Day 1 (14 Dec 2009)

Ms. Cherry Lau (Sr. Technical Executive) was the trainer who presented the four sessions in day 1, including “General principle of GMP”, “Personnel; training; sanitization & cleaning”, “Premises & equipment; qualification & validation” and “Complaints; deviations; returns; recalls; contract production & testing; self inspections; quality audit”.

The following figure showed the GxP in different pharmaceutical legislative cycle. It is a very useful to overview the whole picture of GLP/GCP/GMP.

GMP applies to “Critical” processes, which means any process that directly or indirectly may have a negative impact on safety, quality or efficacy of the product are concerned. It ensures quality, safety and efficacy of drugs delivered to patients.

The GMP manufacturing site diagram

Quality Relationships:

Quality Management > Quality Assurance > GMP > Quality Control and Manufacturing

In ISO 9000:2005, the definition of audit and inspection are given in following:

Audit: systematic, independent and documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which audit criteria are fulfilled.

Inspection: conformity evaluation by observation and judgment accompanied as appropriate by measurement, testing or gauging.

It has some different interpretation in GMP below.

Inspections are carried out by government agencies (also called the Competent Authorities).

Audits are preformed by drug companies (also called the Marketing Authorization Holder), including:

- Internal self-inspections

- External audits of suppliers and contractors

Personnel requirements were also introduced. Individuals must receive training in GMP:

- initial training

- continuing training, including hygiene standards

Heads of Production and Quality Control should be independent of each other but they may share some responsibilities depending on the national regulations such as authorization of written procedures (SOPs) and other documents, environmental monitoring and control, process validation and calibration, training, etc.

For Sanitation and Hygiene requirements, all aspects of manufacturing should be considered including personnel, premises, equipment, apparatus, production materials and container, and all potential sources of cross-contamination.

The following factors should be considered to prevent cross-contamination.

- Segregated areas for production

- Ventilation systems and airlocks

- Clothing

- Closed processing systems

- Cleaning and decontamination

The manufacturing environment is critical for product quality, such as light, temperature, humidity, air movement, microbial contamination, particulate contamination, etc.

The different classifications of cleanroom were shown.

The validation requirements of cGMP were shown in the following sequence.

i) User Requirement Specification (URS)

ii) Impact assessment

iii) Design Review (DR) or Design Qualification (DQ)

iv) Commissioning / Qualification

v) Installation Qualification (IQ)

vi) Operational Qualification (OQ)

vii) Performance Qualification (PQ)

viii) Cleaning Validation (CV)

ix) Process Validation (PV)

One of the most important documents for GMP inspection is Validation Master Plan (VMP) which should contain at least:

i) Validation policy

ii) Organization structure

iii) Summary of facilities, systems, equipment, processes to be validated

iv) Documentation format for protocols and reports

v) Planning and scheduling

vi) Change control

vii) Training requirement

Reference:

USA 21 CFR on Food and Drugs, parts 210 and 211.

US GMP: http://www.gpoaccess.gov/cfr/index.html

EU Commission Directive 2003/94/EC; for human drugs

EU Commission Directive 91/412/EEC; for veterinary drugs

EU GMP: http://www.ec.europa.eu/enterprise/pharmaceuticals/eudralex/index.htm

USA 21 CFR on Food and Drugs, parts 210 and 211.

US GMP: http://www.gpoaccess.gov/cfr/index.html

EU Commission Directive 2003/94/EC; for human drugs

EU Commission Directive 91/412/EEC; for veterinary drugs

EU GMP: http://www.ec.europa.eu/enterprise/pharmaceuticals/eudralex/index.htm

2009年12月10日星期四

Dinner with Prof. Hiroshi OSADA (Deming Prize Winner 2009)

Tonight, HKSQ executive committee members had a dinner with Prof. Hiroshi Osada (Professor in Department of MOT (Management of Technology), Graduate School of Innovation Management, Tokyo Institute of Technology). He is the 2009 Deming Prize recipient from JSQC. Prof. Osada came over for a few days for IEEE conference organized in Hong Kong. We were glad to meet him this time and have opportunity to exchange views on quality.

(Center: Prof. OSADA)

(Center: Prof. OSADA)

The Deming prize was established in December 1950 in honor of W. Edwards Deming. It was originally designed to reward Japanese companies for major advances in quality improvement. There are four categories of Deming prize:

i) The Deming Prize for Individuals

ii) The Deming Application Prize

iii) The Quality Control Award for Operations Business Units

iv) The Japan Quality Medal

I would like to introduce the Deming Prize for Individuals below.

The Deming Prize for Individuals is an annual award grand to:

a) individuals who have made outstanding contributions to the study of TQM or statistical methods used for TQM, or

b) individuals who have made outstanding contributions in the dissemination of TQM.

(Note: The candidates’ primary activities are limited to outside Japan are not eligible for the prize.)

A new individual prize entitled “Deming Distinguished Service Award for Dissemination and Promotion (Overseas)” was established in 2009. It is an award given to individuals who have made outstanding contributions in the dissemination and promotion of TQM. The candidates’ primary activities must be limited to outside Japan. The first winner is Mr. Gregory H. Watson.

I am the lucky one and have met 5 Deming Prize winners during Asia Network for Quality (ANQ) Congress and ASQ conference since 2001. They are Prof. Yoji AKAO (Deming prize winner in 1978), Prof. Noriaki KANO (Deming prize winner in 1997), Prof. Yoshinori IIZUKA (Deming prize winner in 2006), Mr. Gregory H. WATSON (Deming prize (overseas) winner in 2009) and Prof. Hiroshi OSADA (Deming prize winner in 2009).

Photo with KANO (ASQ Conference in 2005)

(Left: Prof. Yoji AKAO; Right: Dr. Kozo KOURA)

(Left: Prof. Yoji AKAO; Right: Dr. Kozo KOURA)

Photo with IIZUKA (ANQ Congress 2007)

(Center: Prof. OSADA)

(Center: Prof. OSADA)The Deming prize was established in December 1950 in honor of W. Edwards Deming. It was originally designed to reward Japanese companies for major advances in quality improvement. There are four categories of Deming prize:

i) The Deming Prize for Individuals

ii) The Deming Application Prize

iii) The Quality Control Award for Operations Business Units

iv) The Japan Quality Medal

I would like to introduce the Deming Prize for Individuals below.

The Deming Prize for Individuals is an annual award grand to:

a) individuals who have made outstanding contributions to the study of TQM or statistical methods used for TQM, or

b) individuals who have made outstanding contributions in the dissemination of TQM.

(Note: The candidates’ primary activities are limited to outside Japan are not eligible for the prize.)

A new individual prize entitled “Deming Distinguished Service Award for Dissemination and Promotion (Overseas)” was established in 2009. It is an award given to individuals who have made outstanding contributions in the dissemination and promotion of TQM. The candidates’ primary activities must be limited to outside Japan. The first winner is Mr. Gregory H. Watson.

I am the lucky one and have met 5 Deming Prize winners during Asia Network for Quality (ANQ) Congress and ASQ conference since 2001. They are Prof. Yoji AKAO (Deming prize winner in 1978), Prof. Noriaki KANO (Deming prize winner in 1997), Prof. Yoshinori IIZUKA (Deming prize winner in 2006), Mr. Gregory H. WATSON (Deming prize (overseas) winner in 2009) and Prof. Hiroshi OSADA (Deming prize winner in 2009).

Photo with KANO (ASQ Conference in 2005)

Photo with AKAO (ASQ Conference in 2005)

(Left: Prof. Yoji AKAO; Right: Dr. Kozo KOURA)

(Left: Prof. Yoji AKAO; Right: Dr. Kozo KOURA) Photo with IIZUKA (ANQ Congress 2007)

For more information,

OSADA Laboratory: http://www.geocities.jp/osada_lab/

The W. Edwards Deming Institute: http://deming.org/

2009年12月4日星期五

InnoAsia 09 Conference (Sustainable Transportation / Energy)

InnoAsia 09 Conference was held from 1st to 2nd December 2009. The theme called “SUSTAINABLE City, Transportation & Energy”. I joined sessions entitled “Sustainable City” on Day 1 and “Sustainable Tansportation / Energy” on Day 2. The summary was shown as follows.

Sustainable Transportation / Energy (Day 2)

The first speaker was Dr. Didier Kechemair (Executive Deputy Director, Division for International Affairs, French Atomic Energy Cmmission (CEA). France) and his topic was “Social Demand as a Driving Force for Research and Innovation in a Sustainable Energy Development Context”. He explained three studies related to CEA R&D activities. They were:

i) Energy without CO2: Why should Nuclear play a major role?

ii) Mobility without CO2: How to associate renewable energies applications for transportation and buildings?

iii) From mobility to Nomad: How to take into account customers’ perception in the design & innovation process?

Nuclear plays a major role. 90% of French electricity is carbon-free.

Mobility without CO2

Sustainable Transportation / Energy (Day 2)

The first speaker was Dr. Didier Kechemair (Executive Deputy Director, Division for International Affairs, French Atomic Energy Cmmission (CEA). France) and his topic was “Social Demand as a Driving Force for Research and Innovation in a Sustainable Energy Development Context”. He explained three studies related to CEA R&D activities. They were:

i) Energy without CO2: Why should Nuclear play a major role?

ii) Mobility without CO2: How to associate renewable energies applications for transportation and buildings?

iii) From mobility to Nomad: How to take into account customers’ perception in the design & innovation process?

Nuclear plays a major role. 90% of French electricity is carbon-free.

Mobility without CO2

The second speaker, Mr. Kenichiro Wada (General Manager, EV/Power Train System Engineering Department, Development Engineering Office, Mitsubishi Motors Corporation, Japan) gave a talk entitled “Development of New Generation Electric Vehicle i-MiEV”. The history of Mitsubishi’s EVs development and the feathers of i-MiEV were introduced. The MiEV operation system included Safety and Security, Energy Saving, as well as, Comfort were also discussed.

Five aspects of the i-MiEV

Reliability Test

Running over water

The collaboration with Hong Kong Government (EPD) was shown.

Mr. Wada concluded that in order to contribute in prevention of global warming and move toward independence from fossil fuels, Mitsubishi Motors is leading the change toward electric vehicles.

The third speaker was Mr. Thomas Nagy (Executive Vice President, Stakeholder Relations, Novozymes A/S, Denmark) and his topic was “Change the World – Bio-innovation for Environmental & Economic Benefits”. They provide industrial enzymes, microorganisms and biopharmaceutical ingredients. He pointed out the global challenges included financial / economic crisis, increasing unemployment, growing population, depleting resources and climate change. It indicated that the world was becoming Hot, Flat & Crowded.

He shared the enzyme technology which was used in the 2nd generation biofuel. Those commercial enzymes could produce bioethanol from agricultural waste. Compared with gasoline, using of biofuel could reduce CO2 emissions by 90%.

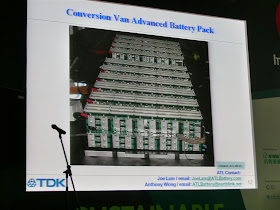

In Panel Session, Dr. Raymond Leung (Chairman and CEO, TDK China Co., Ltd.) was invited to give a talk entitled “Sustainable Transportation – EV Market Dynamics, Drive Train, Battery Technology”. He said zero emission vehicle is the one of important market trend.

LiFeP/Graphite Cell was developed in HK and it was deployed in China (Beijing).

Five aspects of the i-MiEV

Reliability Test

Running over water

The collaboration with Hong Kong Government (EPD) was shown.

Mr. Wada concluded that in order to contribute in prevention of global warming and move toward independence from fossil fuels, Mitsubishi Motors is leading the change toward electric vehicles.

The third speaker was Mr. Thomas Nagy (Executive Vice President, Stakeholder Relations, Novozymes A/S, Denmark) and his topic was “Change the World – Bio-innovation for Environmental & Economic Benefits”. They provide industrial enzymes, microorganisms and biopharmaceutical ingredients. He pointed out the global challenges included financial / economic crisis, increasing unemployment, growing population, depleting resources and climate change. It indicated that the world was becoming Hot, Flat & Crowded.

He shared the enzyme technology which was used in the 2nd generation biofuel. Those commercial enzymes could produce bioethanol from agricultural waste. Compared with gasoline, using of biofuel could reduce CO2 emissions by 90%.

In Panel Session, Dr. Raymond Leung (Chairman and CEO, TDK China Co., Ltd.) was invited to give a talk entitled “Sustainable Transportation – EV Market Dynamics, Drive Train, Battery Technology”. He said zero emission vehicle is the one of important market trend.

LiFeP/Graphite Cell was developed in HK and it was deployed in China (Beijing).

Dr. Leung showed “The test driving the first EV sports car in the world”.

The last speaker was Dr. Ying Yang (CEO, Hong Kong Auto Parts and Accessory Systems R&D Centre (APAS)) and his topic was “Key components for Electric Vehicles: Challenges and Opportunities”. He discussed the technical challenges on electric vehicles included Battery, Battery Management System (BMS), Brake by Wire, Power Electronics, Vehicle Controller and Control Strategies, Electrical Powered Air Conditioning, etc. He commented they could be the business opportunities.

Panel discussion was organized at the end.

The last speaker was Dr. Ying Yang (CEO, Hong Kong Auto Parts and Accessory Systems R&D Centre (APAS)) and his topic was “Key components for Electric Vehicles: Challenges and Opportunities”. He discussed the technical challenges on electric vehicles included Battery, Battery Management System (BMS), Brake by Wire, Power Electronics, Vehicle Controller and Control Strategies, Electrical Powered Air Conditioning, etc. He commented they could be the business opportunities.

Panel discussion was organized at the end.

2009年12月3日星期四

InnoAsia 09 Conference (Sustainable City)

InnoAsia 09 Conference was held from 1st to 2nd December 2009. The theme was called “SUSTAINABLE City, Transportation & Energy”. I attended sessions entitled “Sustainable City” on Day 1 and “Sustainable Transportation / Energy” on Day 2. The summary was shown as follows.

Sustainable City (Day 1)

In the beginning, Mr. Nicholas Brooke (Chairman – HKSTP) gave the opening speech to introduce InnoAsia Conference.

Mr. Edward Yau (JP, Secretary for the Environment, The Government of HKSAR) shared the environmental policies and some insight for the theme.

The opening ceremony was started by irrigation plants by all VIPs.

The first speaker was Mr. Ilmar Reepalu (Mayor, Malmo stad (Sweden)) and his topic was “Making Sustainability Reality – Creating the Sustainable City of Tomorrow”. He compared different environmental policies employed to the city including renewal energy, transportation, etc. Waste management such as reduction the usage of natural resources, prioritization of reuse and recycling, optimization of refuse collection and separation of organic waste, were discussed.

The following figure showed Zero-emission heating and cooling system.

The second speaker, Mr. Tom Murphy (Sr. Resident Fellow, Urban Development, the Urban land Institute (USA) and Former Mayor of Pittsburgh) gave a talk named “Building a World Class Region, Competing in a Changing World”.

He stated building a World Class Region in 5 dimensions as follows:

i) Infrastructure

ii) Regional Cooperation

iii) Quality of Life

iv) Competitive Advantage

v) Leadership

Mr. Chris Twinn (Director, Building Engineering Sustainability Group, Ove Arup & Partners (UK)) was the third speaker and his topic was “Zero Carbon Communities – Moving Theory into Practice”.

He mentioned COP 15 Copenhagen expectation that developed countries need to achieve about 90% carbon emissions reduction across all sectors by 2050.

Then he explained Zero Carbon operating in the following photo.

The Hong Kong Science Park Phase 3 – Sustainability Masterplan, which could be a route map to zero carbon, was also discussed.

Lastly, he concluded that:

i) A step-change is possible

ii) Challenging for unfamiliar industry

iii) Consumers ultimately pay

iv) Governments should lead the role in setting market framework

v) Learning from experience is proving essential

vi) Practitioners need to help national policy development

Panel discussion was held at the end.

Sustainable City (Day 1)

In the beginning, Mr. Nicholas Brooke (Chairman – HKSTP) gave the opening speech to introduce InnoAsia Conference.

Mr. Edward Yau (JP, Secretary for the Environment, The Government of HKSAR) shared the environmental policies and some insight for the theme.

The opening ceremony was started by irrigation plants by all VIPs.

The first speaker was Mr. Ilmar Reepalu (Mayor, Malmo stad (Sweden)) and his topic was “Making Sustainability Reality – Creating the Sustainable City of Tomorrow”. He compared different environmental policies employed to the city including renewal energy, transportation, etc. Waste management such as reduction the usage of natural resources, prioritization of reuse and recycling, optimization of refuse collection and separation of organic waste, were discussed.

The following figure showed Zero-emission heating and cooling system.

The second speaker, Mr. Tom Murphy (Sr. Resident Fellow, Urban Development, the Urban land Institute (USA) and Former Mayor of Pittsburgh) gave a talk named “Building a World Class Region, Competing in a Changing World”.

He stated building a World Class Region in 5 dimensions as follows:

i) Infrastructure

ii) Regional Cooperation

iii) Quality of Life

iv) Competitive Advantage

v) Leadership

Mr. Chris Twinn (Director, Building Engineering Sustainability Group, Ove Arup & Partners (UK)) was the third speaker and his topic was “Zero Carbon Communities – Moving Theory into Practice”.

He mentioned COP 15 Copenhagen expectation that developed countries need to achieve about 90% carbon emissions reduction across all sectors by 2050.

Then he explained Zero Carbon operating in the following photo.

The Hong Kong Science Park Phase 3 – Sustainability Masterplan, which could be a route map to zero carbon, was also discussed.

Lastly, he concluded that:

i) A step-change is possible

ii) Challenging for unfamiliar industry

iii) Consumers ultimately pay

iv) Governments should lead the role in setting market framework

v) Learning from experience is proving essential

vi) Practitioners need to help national policy development

Panel discussion was held at the end.